Electron shift type electric field intensity sensor

A technology of electric field strength and sensors, applied in the fields of electromagnetic field characteristics, electrostatic field measurement, instruments, etc., can solve problems such as poor product consistency, poor environmental adaptability, and low resolution, and achieve small electric field energy loss, good applicability, and high resolution high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

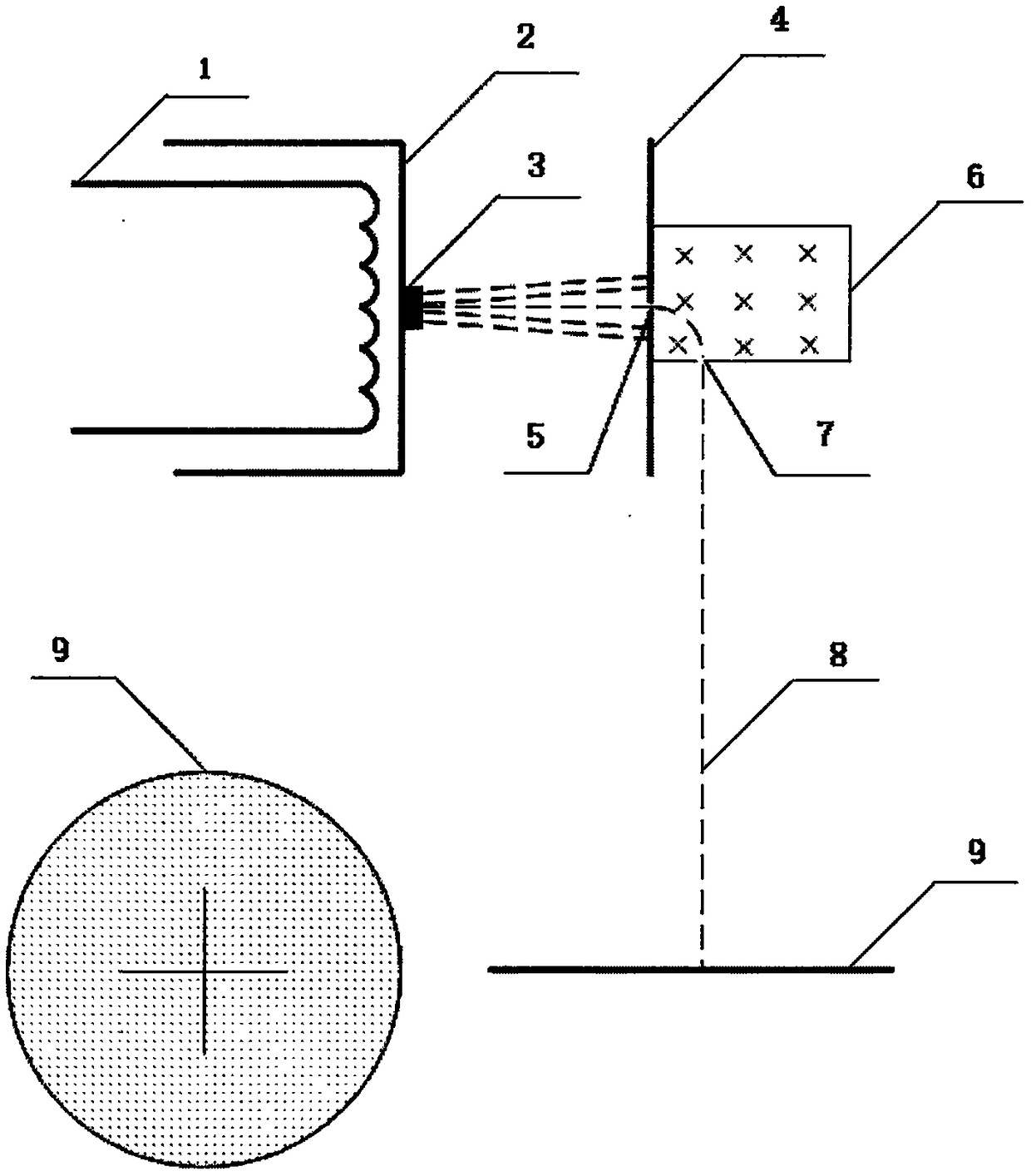

[0021] Example 1: figure 1 It is an implementation form of electronic offset electric field strength sensor. As shown in the figure, this embodiment is mainly composed of heating electrode, emitting cathode, accelerating electric field cathode, accelerating electric field anode, accelerating electric field anode small hole, screening magnetic field generating device, speed Screening pinholes, composed of charge-coupled devices. The emitting cathode emits electrons after being heated, and the electrons move forward under the action of the accelerating electric field. The accelerating electric field makes the electrons emitted by the cathode have a greater forward speed in all directions, and most of the electrons fly to the anode. Among the electrons going to the anode of the electric field, some electrons pass through the anode hole on the anode plate and enter the screening magnetic field. The screening magnetic field is a uniform magnetic field. Under the action of the magne...

Embodiment 2

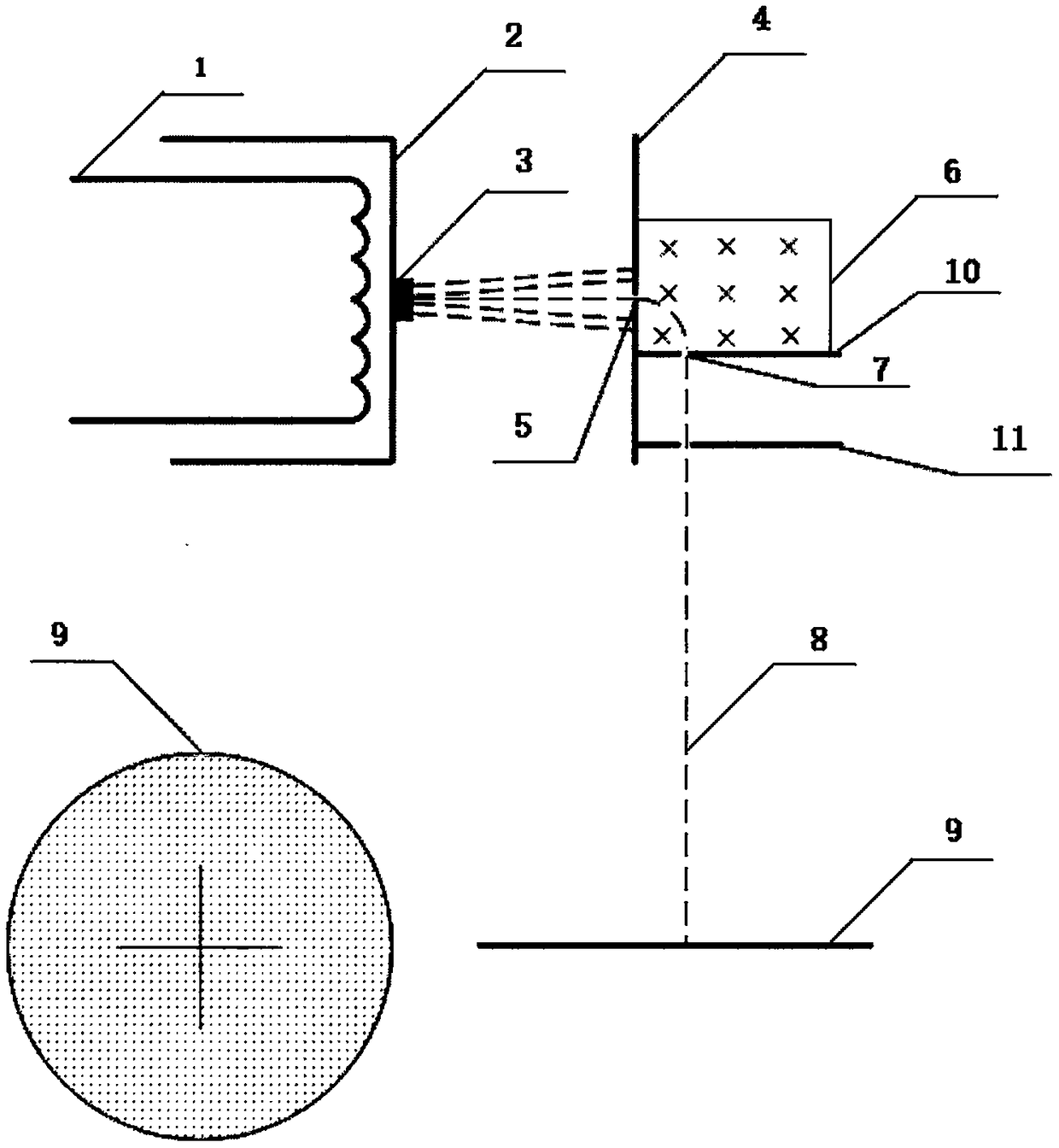

[0023] Embodiment 2: On the basis of Embodiment 1, a decelerating electric field is added after the magnetic field is screened, which becomes the second embodiment of the present invention. Such as figure 2As shown, this embodiment is mainly composed of a heating electrode, an emitting cathode, an accelerating electric field cathode, an accelerating electric field anode, an accelerating electric field anode aperture, a screening magnetic field generating device, a velocity screening aperture, a decelerating electric field and a charge coupled device. The emitting cathode emits electrons after being heated, and the electrons move forward under the action of the accelerating electric field. The accelerating electric field makes the electrons emitted by the cathode have a greater forward speed in all directions, and most of the electrons fly to the anode. Among the electrons going to the anode of the electric field, some electrons pass through the anode hole on the anode plate a...

Embodiment 3

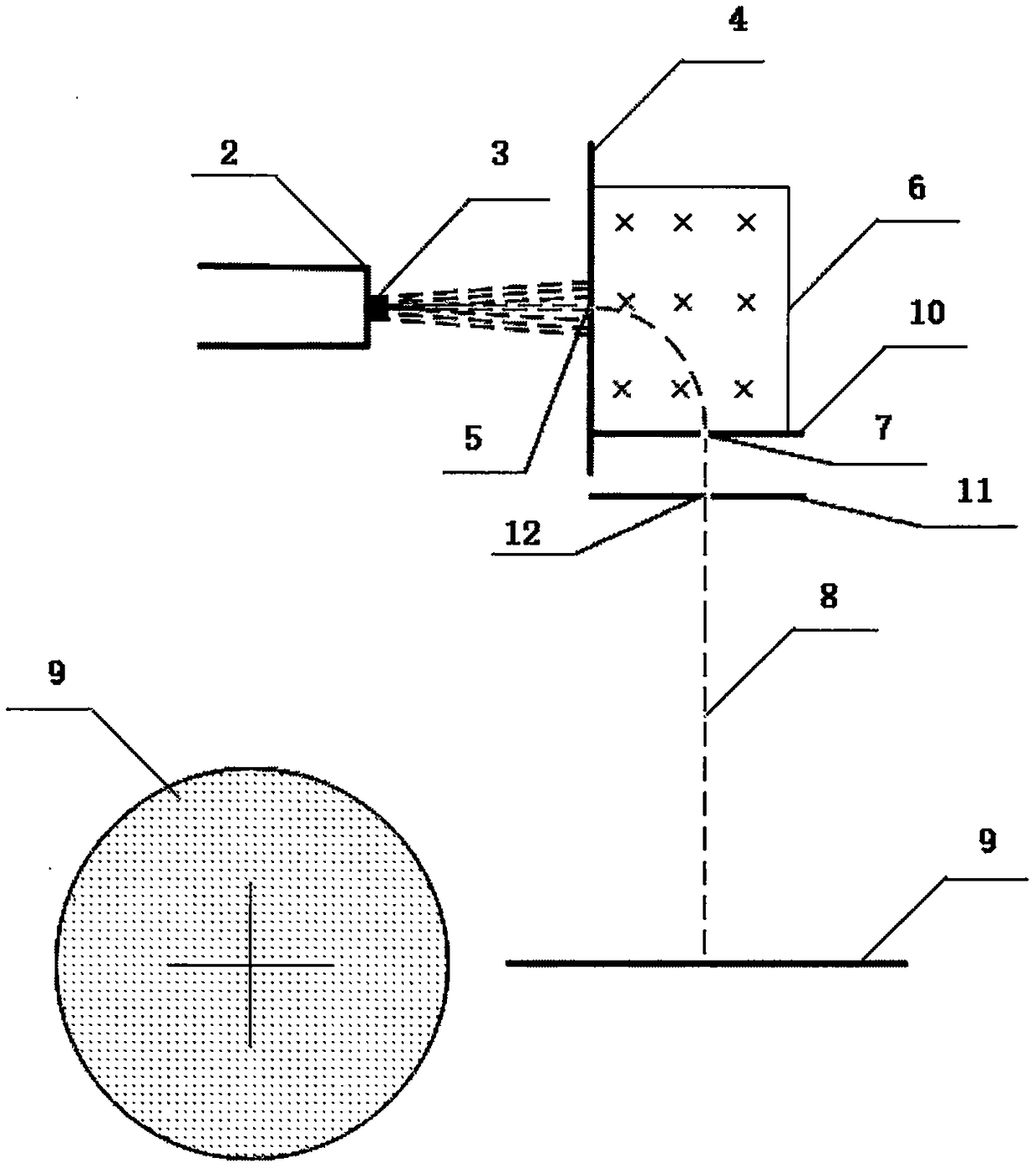

[0025] Embodiment 3: On the basis of Embodiment 2, after canceling the cathode heating device, field electron emission is used, which becomes the third embodiment of the present invention. like image 3 As shown, this embodiment is mainly made up of emitting cathode, accelerating electric field cathode (also serving as emission control grid), accelerating electric field anode, accelerating electric field anode aperture, screening magnetic field generating device, speed screening aperture, decelerating electric field and charge-coupled device . Apply a high voltage to the accelerating electric field, and the emitting cathode emits electrons under the action of the high voltage, and the electrons move forward under the action of the accelerating electric field. The high-voltage accelerating electric field makes the electrons emitted from the cathode in all directions have a great forward direction Speed, most of the electrons fly to the anode. Among the electrons flying to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com