Chemico-mechanical polishing method of metal interconnection line with ruthenium barrier layer

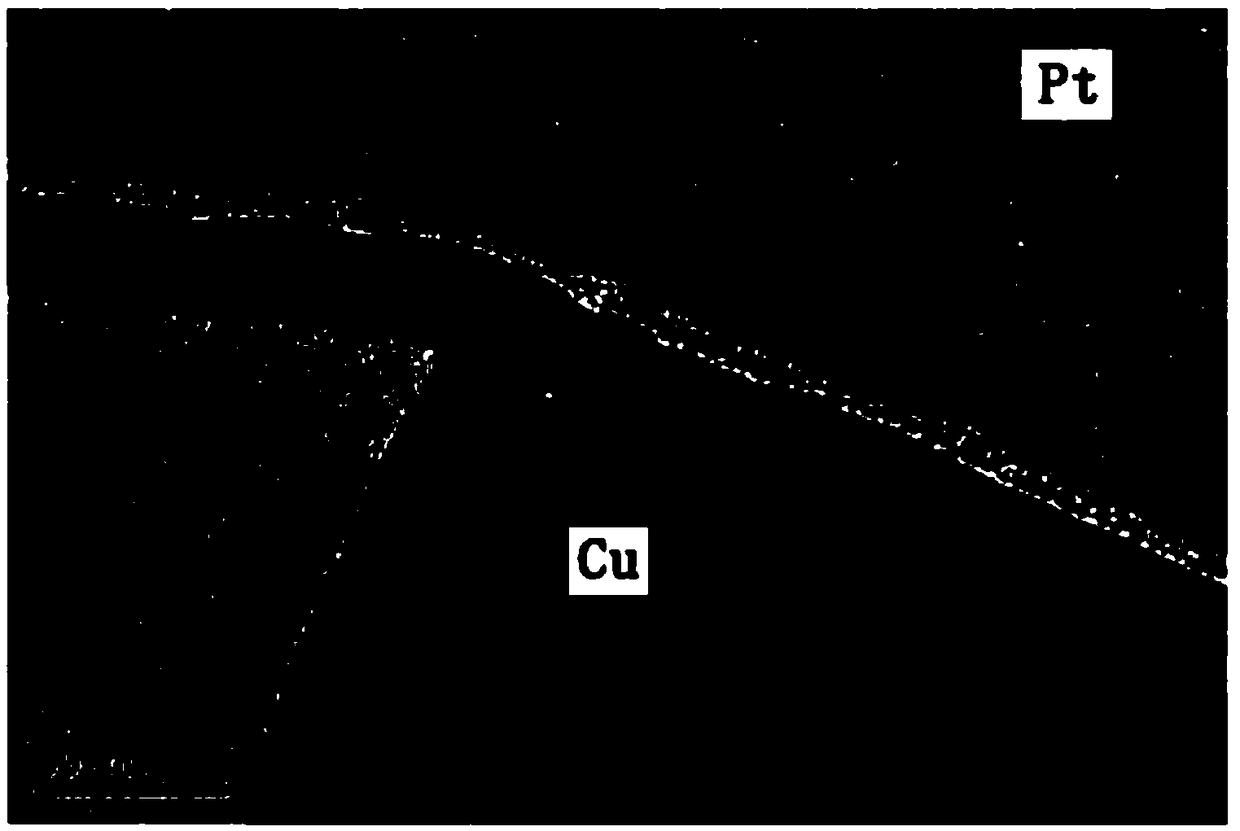

A technology of barrier layer and polishing liquid, applied in the field of polishing liquid, to achieve the effect of good flatness, good wafer surface and interface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The preparation method of the first polishing liquid and the second polishing liquid is as follows: according to the composition ratio of the first polishing liquid and the second polishing liquid, SiO 2 Abrasive particles were added to deionized water, followed by oxidizing agent (H 2 O 2 ), triazole-based corrosion inhibitor (1,2,4-triazole) and other chemical components, stir with a magnetic stirrer for 30 minutes, and use magnetic force in the chemical mechanical polishing process of the first polishing solution and the second polishing solution. The agitator keeps stirring.

[0053] The chemical mechanical polishing method applied includes: using Universal-150 polishing machine (Tianjin Huahai Qingke Electromechanical Technology Co., Ltd.), using IC1000 polishing pads in the first polishing process and the second polishing process, using PolitexReg polishing pads in the third polishing process, After the third polishing process, the wafer surface was cleaned with...

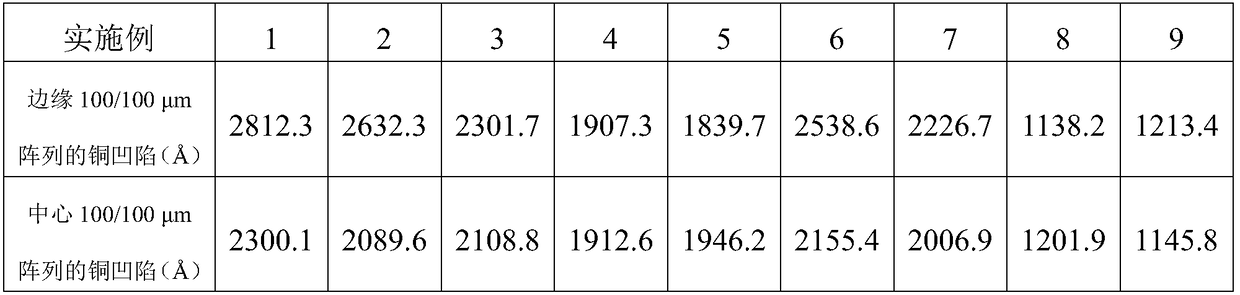

Embodiment 1

[0056] Use a square pattern wafer with a side length of 1.55 inches. Copper polishing process: P1 polishing pressure is 2.0psi, OP polishing pressure is 1.3psi, the first polishing liquid flow rate is 130mL / min, the polishing speed is 90 / 100rpm, and the first polishing liquid contains 1wt.%H 2 O 2 , 5wt.%SiO 2 Abrasive, using IC1000 polishing pad.

Embodiment 2

[0058] Use a square pattern wafer with a side length of 1.55 inches. Copper polishing process: P1 polishing pressure is 1.5psi, OP polishing pressure is 1.3psi, the first polishing liquid flow rate is 130mL / min, the polishing speed is 90 / 100rpm, and the first polishing liquid contains 1wt.%H 2 O 2 , 5wt.%SiO 2 Abrasive, using IC1000 polishing pad.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com