3D printing high-strength artificial stone pattern die and preparation method thereof

A 3D printing, artificial stone technology, applied in the field of 3D printing high-strength artificial stone pattern mold and its preparation, can solve the problems of insufficient mold strength, insufficient strength, short life, etc., to achieve low comprehensive use cost, reduced cleaning time, and use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing a 3D printing high-strength artificial stone pattern mold, comprising the following steps:

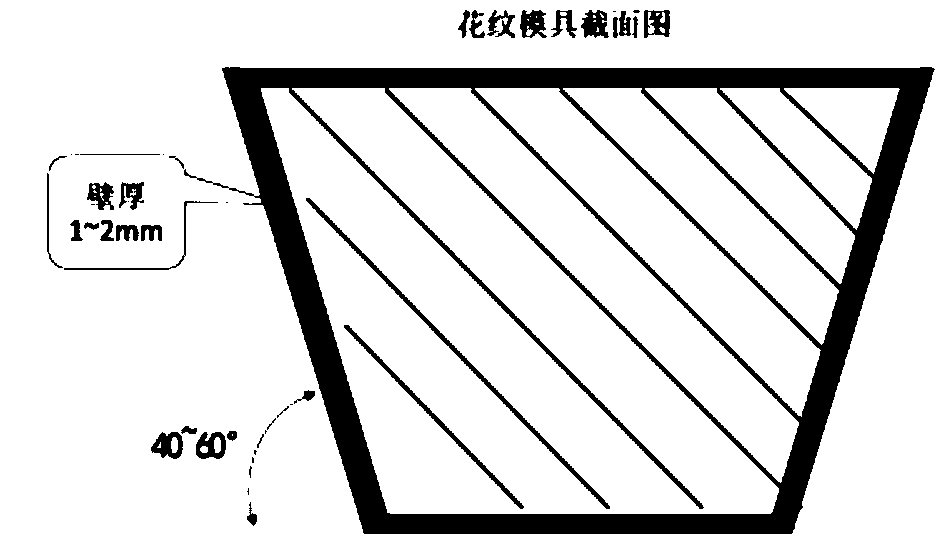

[0032] 1. Draw a CAD three-dimensional drawing according to the desired pattern. The gradient of the section of the pattern mold is 50° and the height is 10mm.

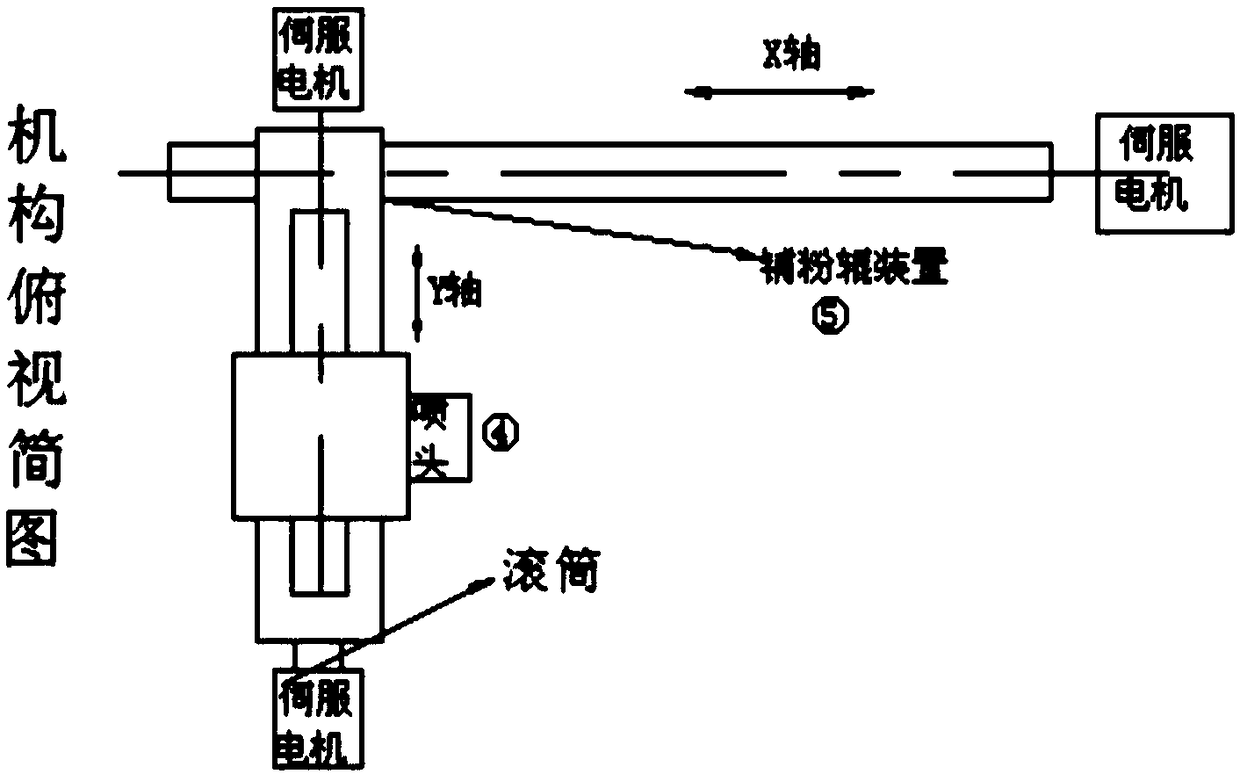

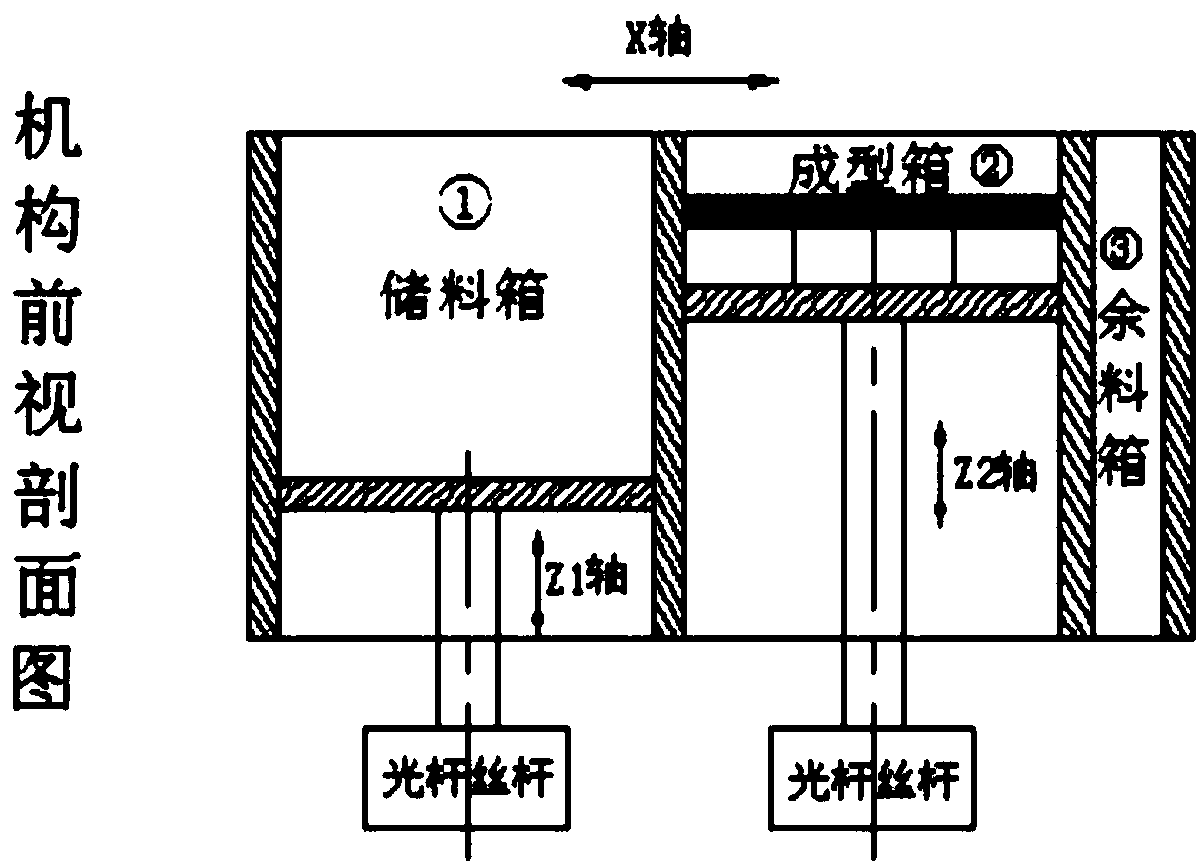

[0033] 2. Enter the CAD three-dimensional drawing drawn in step 1 into the 3D printer, and add 316L stainless steel powder into the material cavity, and the particle diameter is 15-45um.

[0034] 3. Adjust the flow rate of the powder to 10s / 50g, the moving speed to 2cm / s and the temperature of the laser beam to 1399-1455°C, and start printing.

[0035] 4. After printing, temper at 1000-1050°C to eliminate stress.

[0036] 5. Finally, perform surface treatment, grinding and polishing, the mesh number ranges from 800-5000 mesh, and finally obtain the 3D printed high-strength artificial stone pattern mold with a wall thickness of 1-2mm.

[0037] In the 3D printed high-strength artificial stone pat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com