Mercaptoazole derivatives as lubricating additives

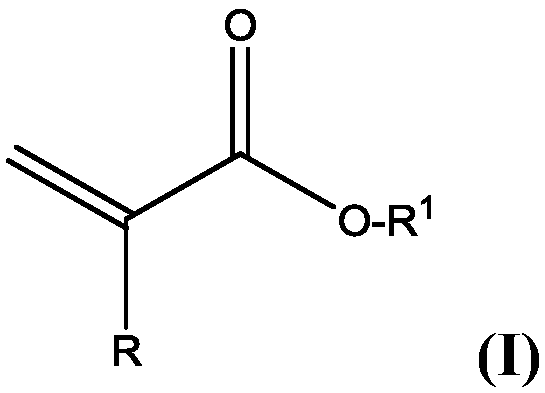

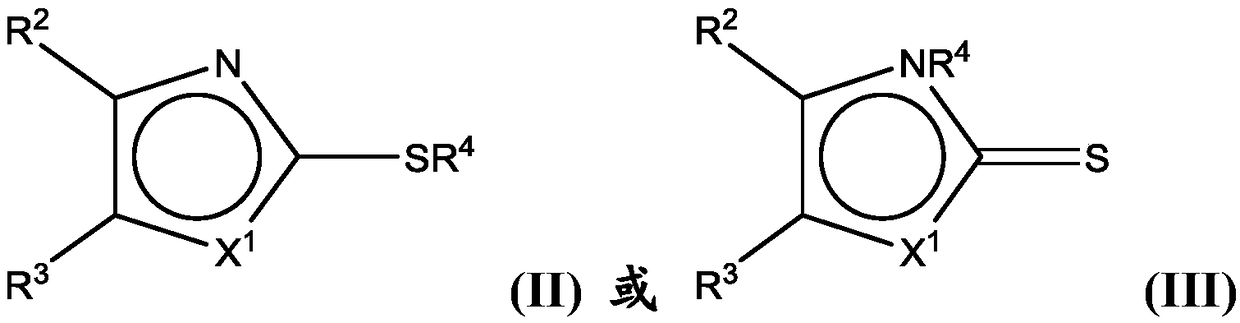

A technology of mercaptopyrrole and its derivatives, which can be used in additives, lubricating compositions, petroleum industry, etc., and can solve the problems of insufficiently solved lubricating oil corrosion inhibition requirements, seal wear, lead corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A-1

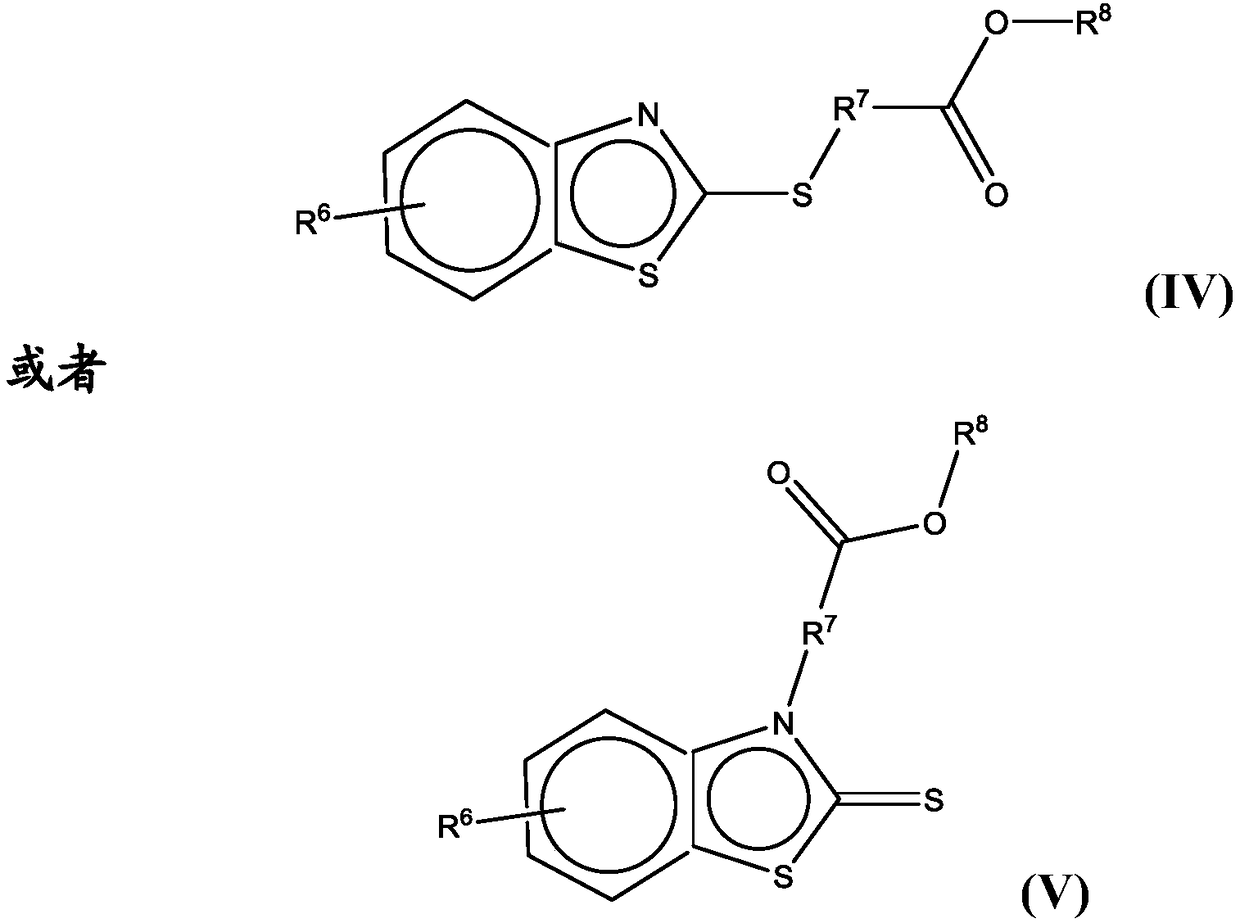

[0142] The reaction product of embodiment A-1—2-mercaptobenzothiazole and 2-ethylhexyl acrylate

[0143] For Example A-1, 2-mercaptobenzothiazole MBZL (100 grams, 0.6 moles), 2-ethylhexyl acrylate (111 grams, 0.6 moles), triethylamine (60 grams, 0.6 moles) and 300 Add a mixture of mL of acetonitrile and THF to a 4-necked 1 L round bottom flask. The mixture was stirred vigorously to facilitate the dissolution of MBZL. The reaction was maintained between 50°C and 75°C until the reaction was complete. The reaction mixture containing the mercaptopyrrole-acrylic acid adduct was obtained by rotary evaporation and filtration through calcined celite.

Embodiment A-2

[0144] The reaction product of embodiment A-2 (forecast)-2-mercapto-1,3,4-triazole and 2-ethylhexyl acrylate

[0145] For Example A-2, 2-mercapto-1,3,4-triazole and 2-ethylhexyl acrylate were reacted under the same reaction conditions as in Example A-1.

Embodiment A-3

[0146] The reaction product of embodiment A-3 (forecast)-5-mercaptoimidazole and 2-ethylhexyl acrylate

[0147] For Example A-3, 5-mercaptoimidazole and 2-ethylhexyl acrylate were reacted under the same reaction conditions as in Example A-1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com