Pet food prepared by combining freeze-dried meat with puffed staple food

A technology of pet food and carcass, applied in the field of pet food, can solve the problems of pet malnutrition and inability to meet the nutritional needs of pets, and achieve the effect of ensuring safety and palatability, nutrition and palatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] Its preparation method comprises the following steps:

[0039] Step 1. Making puffed body:

[0040] A. Raw materials such as corn, soybean meal, rice, linseed and other plant-derived components, as well as animal-derived components such as chicken powder and meat and bone meal, are first coarsely pulverized and then ultrafinely pulverized, and the particle size reaches 80-100 mesh;

[0041] B. The raw material yeast extract, xylo-oligosaccharide and other prebiotics and compound minerals are directly ultra-finely pulverized, and the particle size reaches 80-100 mesh;

[0042] C. Mix the above pulverized raw materials for 20-60 minutes, and add 10-30% of water;

[0043] D. Add the mixed raw materials into the feeding port of the twin-screw extruder, adjust the operating parameters of the twin-screw extruder, and obtain the puffed staple grain body;

[0044] Step 2, spraying the adhesion layer: mixing animal fat and vegetable oil to form an adhesion layer, spraying it on ...

Embodiment 1

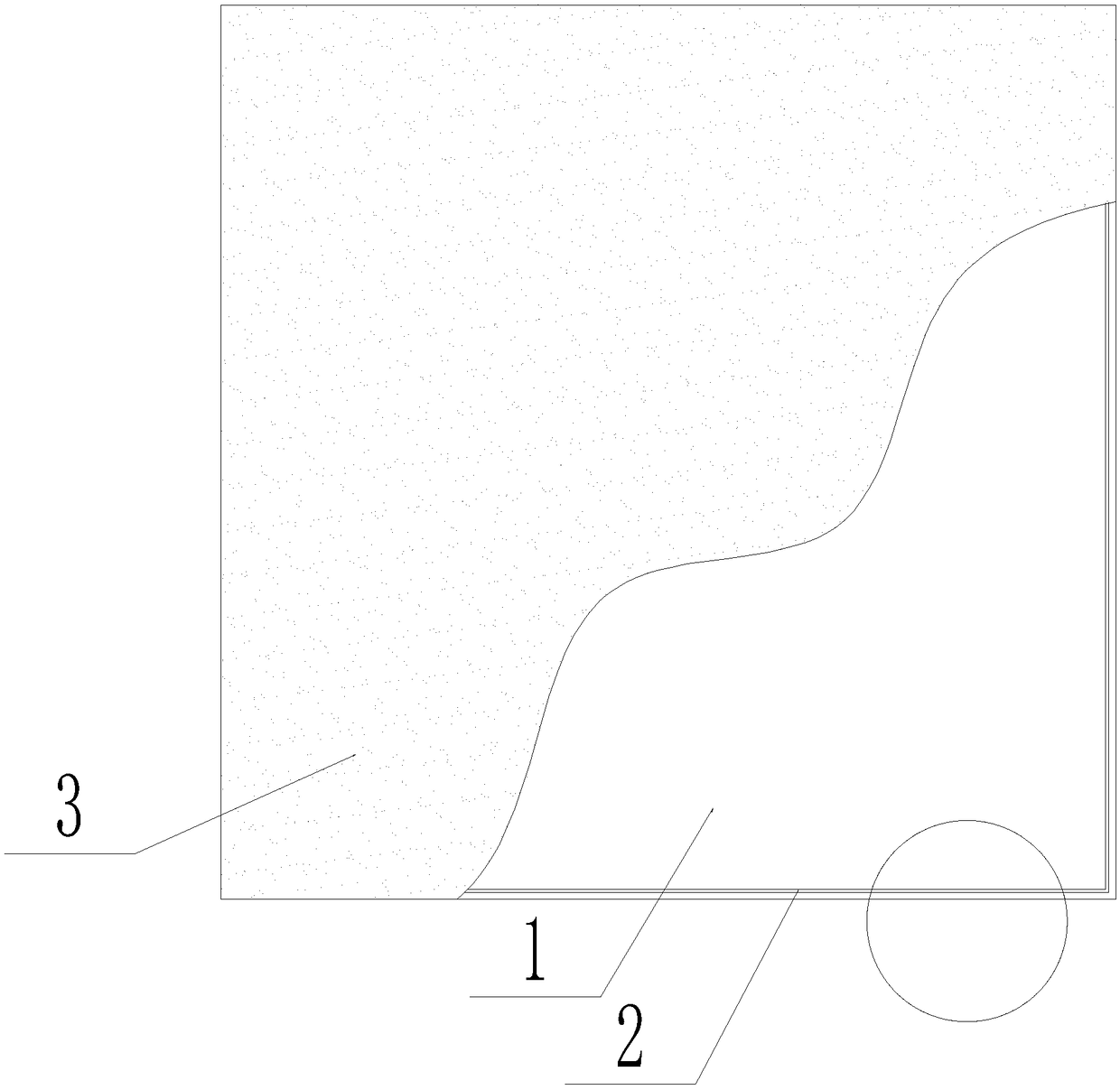

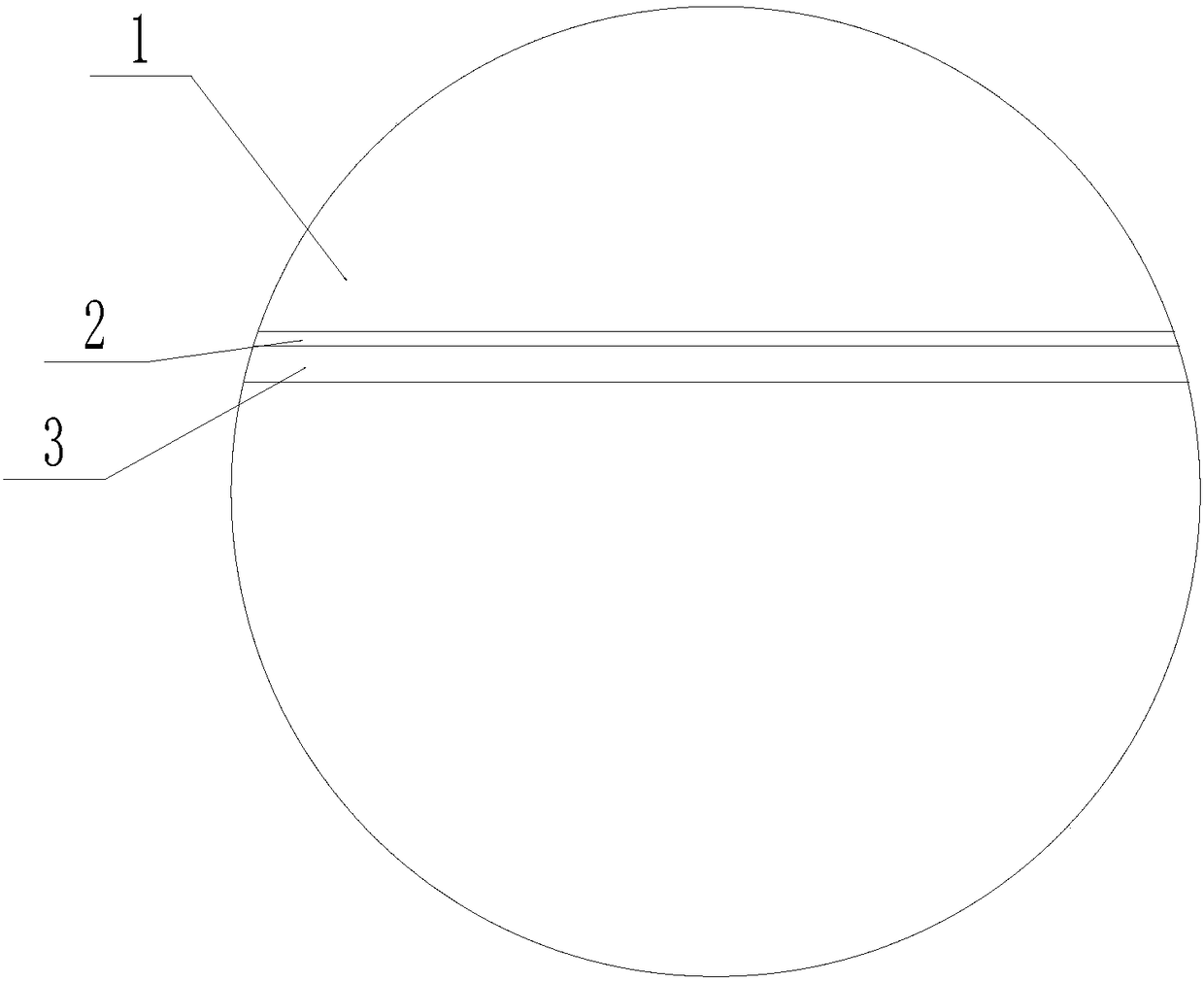

[0055] according to figure 1 with figure 2 As shown, the meat or viscera (such as liver) of pure chicken, pure duck, pure beef, pure salmon or pure tuna, etc. The meat floss is made into a meat floss layer, and then the meat floss layer is adhered to the adhesive layer.

Embodiment 2

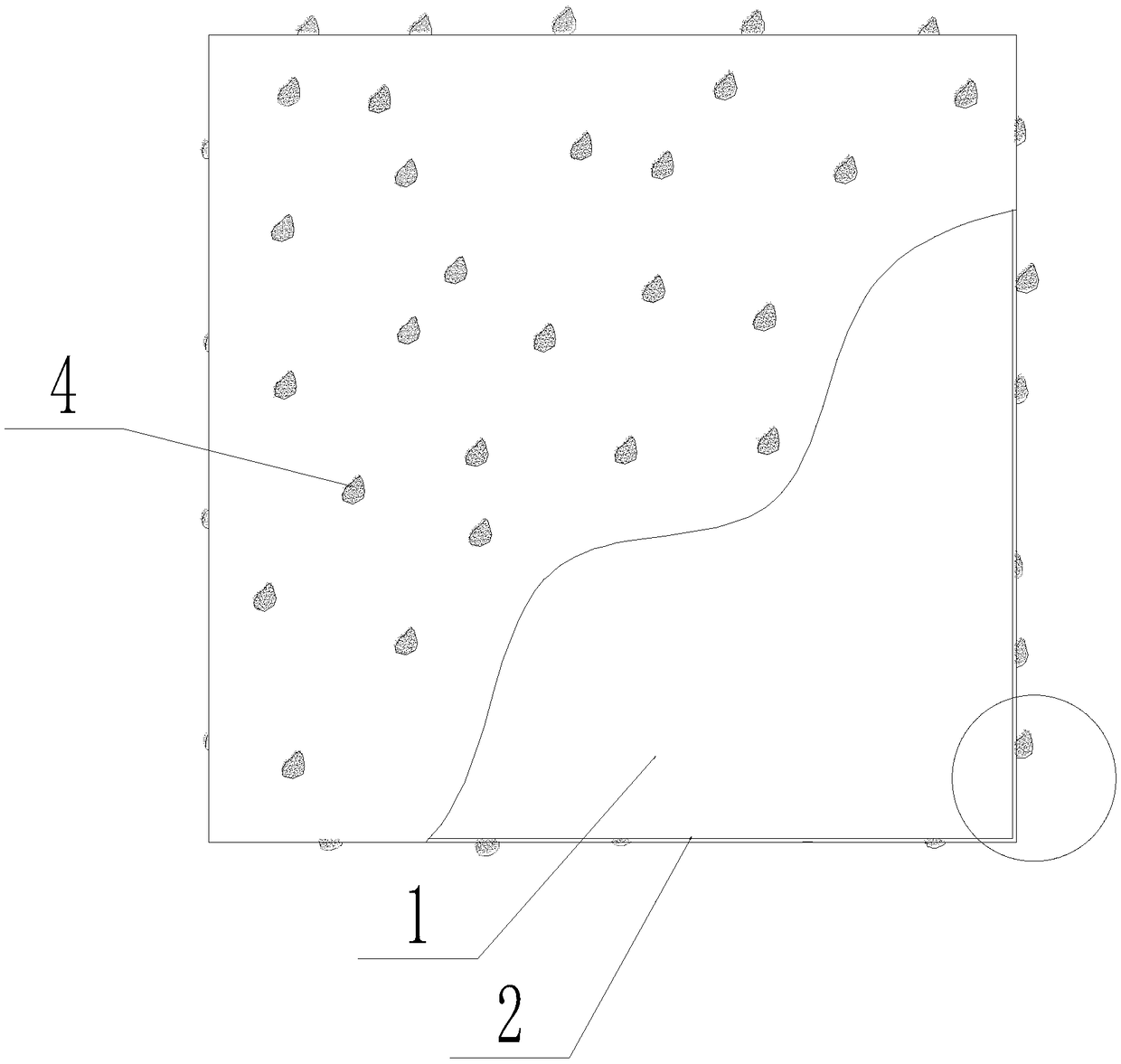

[0057] according to image 3 with Figure 4 As shown, the meat floss layer is adhered on the adhesive layer, and the meat or viscera (such as liver) of livestock such as chicken or duck meat or beef or salmon meat or tuna meat, poultry or fish, shrimp and shellfish (such as liver) are made into meat with a meat grinder. Stuffing, vegetables, and fruits are chopped with a knife; the minced meat, chopped vegetables, fruits and animal fat are mixed; the mixed above-mentioned raw materials are made into a cylindrical shape with a sausage enema machine and then quick-frozen; the quick-frozen raw materials are placed in The freeze-drying device performs vacuum freeze-drying treatment, and after freeze-drying and dehydration, the meat particles can be obtained to make meat particles, and then a plurality of meat particles are adhered to the surface of the adhesion layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com