Preparation method, product and application of mesoporous graphite-phase carbon nitride composed of hollow spheres

A technology of graphite phase carbon nitride and carbon nitride, which is applied in the direction of chemical instruments and methods, nitrogen compounds, nitrogen and non-metallic compounds, etc., can solve the problems of complex preparation process, increase the specific surface area and improve the utilization rate , low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

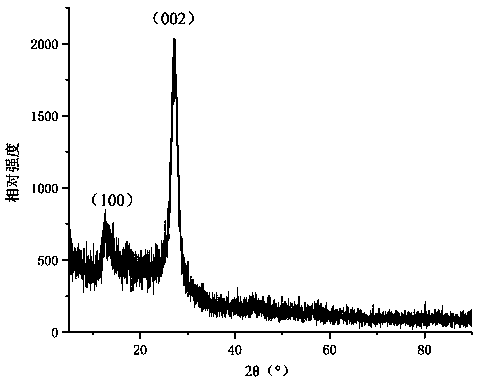

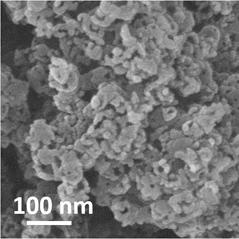

Embodiment 1

[0025] (1) A cylinder with a height of 4 cm and a diameter of 3 cm at the bottom is placed in the center of a 300 ml crucible to form two separated raw material placement spaces at the bottom of the crucible and the top of the cylinder;

[0026] (2) Weighing 0.2g of a 20nm-diameter silica template evenly placed on the top of the cylinder, weighing 2g of melamine evenly placed on the bottom of the crucible, and cover the crucible lid;

[0027] (3) Place the crucible in a muffle furnace and calcinate at 550°C for 4h with a heating rate of 4°C / min;

[0028] (4) The obtained yellow product was treated with 4M NH 4 HF 2 24 hours of processing;

[0029] (5) The product in (4) was washed three times with deionized water and absolute ethanol, and then vacuum-dried at 80° C. for 12 h. The obtained yellow product was mesoporous carbon nitride composed of hollow spheres.

Embodiment 2

[0031] (1) A cylinder with a height of 4 cm and a diameter of 3 cm at the bottom is placed in the center of a 300 ml crucible to form two separated raw material placement spaces at the bottom of the crucible and the top of the cylinder;

[0032] (2) Weighing 0.2g of silica template with a diameter of 20nm is evenly placed on the top of the cylinder, weighing 2g of urea is evenly placed on the bottom of the crucible, and the crucible lid is covered;

[0033] (3) Place the crucible in a muffle furnace and calcinate at 520°C for 4h with a heating rate of 4°C / min;

[0034] (4) The obtained yellow product was treated with 4M NH 4 HF 2 Processing for 24 hours;

[0035] (5) The product in (4) was washed three times with deionized water and absolute ethanol, and then vacuum-dried at 80° C. for 12 h. The obtained yellow product was mesoporous carbon nitride composed of hollow spheres.

Embodiment 3

[0037] (1) A cylinder with a height of 4 cm and a diameter of 3 cm at the bottom is placed in the center of a 300 ml crucible to form two separated raw material placement spaces at the bottom of the crucible and the top of the cylinder;

[0038] (2) The silica template weighing 0.2g of diameter 20nm is evenly placed on the top of the cylinder, the cyanamide weighing 2g is evenly placed on the bottom of the crucible, and the crucible lid is covered;

[0039] (3) Place the crucible in a muffle furnace and calcinate at 550°C for 4h with a heating rate of 4°C / min;

[0040] (4) The obtained yellow product was treated with 4M NH 4 HF 2 Processing for 24 hours;

[0041] (5) The product in (4) was washed three times with deionized water and absolute ethanol, and then vacuum-dried at 80° C. for 12 h. The obtained yellow product was mesoporous carbon nitride composed of hollow spheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com