A kind of preparation method and application of resin asphalt emulsion that improves the adhesion of acidic stone material and asphalt

A technology of resin asphalt and adhesion, which is applied in the field of preparation of resin asphalt emulsion, can solve the problems of limited adhesion ability and poor high temperature stability of anti-stripping agent, and achieve excellent adhesion performance, excellent adhesion performance and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Preparation of surface treatment agent

[0022] Mix 0.1 parts by mass of coupling agent KH-792, 5 parts by mass of 100-mesh quartz sand, and 20 parts by mass of water, and ultrasonically disperse for 10 minutes to obtain a quartz sand dispersion.

[0023] Add 5 parts by mass of cationic epoxy resin emulsion, 5 parts by mass of water-based epoxy curing agent polyamine and 20 parts by mass of cationic emulsified asphalt to the prepared quartz sand dispersion, and stir mechanically at room temperature for 0.5h to obtain a surface Treatment agent resin bitumen emulsion.

[0024] (2) Application of surface treatment agent

[0025] Heating the granite to 180°C, spraying the surface treatment agent resin asphalt emulsion with a mass percentage of 1% of the granite onto the surface of the granite, baking at 180°C for 10 seconds, and obtaining the surface-treated stone after drying.

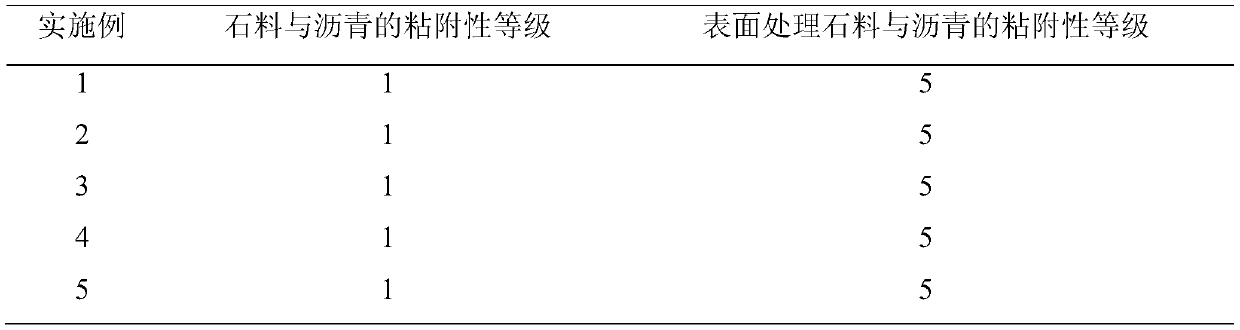

[0026] The adhesion level between stone and asphalt before and after surface treatment wa...

Embodiment 2

[0028] (1) Preparation of surface treatment agent

[0029] After mixing 1 mass part of coupling agent KH-560, 10 mass parts of 400-mesh bentonite, 15 mass parts of 200-mesh white carbon black, and 200 mass parts of water, ultrasonically disperse for 30 minutes to obtain a composite of bentonite and white carbon black. Dispersions.

[0030] Add the nonionic epoxy resin emulsion of 30 mass parts, the phenalkamine of 25 mass parts and the nonionic emulsified asphalt of 100 mass parts in the composite dispersion liquid of the bentonite of preparation and white carbon black, mechanically stir 4h at room temperature, A surface treatment agent resin bitumen emulsion is obtained.

[0031] (2) Application of surface treatment agent

[0032] Heat the granite to 200°C, then spray the surface treatment agent resin asphalt emulsion with a mass percentage of 10% of the granite onto the surface of the granite, bake at 150°C for 20 seconds, and obtain the surface-treated stone after drying....

Embodiment 3

[0035] (1) Preparation of surface treatment agent

[0036] Mix 2 parts by mass of coupling agent KH-602, 35 parts by mass of 200-mesh white carbon black, and 250 parts by mass of water, and ultrasonically disperse for 5 minutes to obtain a white carbon black dispersion.

[0037] Add 50 parts by mass of anionic epoxy resin emulsion, 50 parts by mass of polyamide and 100 parts by mass of anionic emulsified pitch to the prepared silica dispersion, and stir mechanically at room temperature for 0.5h to obtain a surface treatment agent resin asphalt emulsion.

[0038] (2) Application of surface treatment agent

[0039] Heat the sandstone to 150°C, then spray a surface treatment agent with a mass percentage of 0.3% of the sandstone onto the surface of the sandstone, bake at 200°C for 5 seconds, and obtain the surface-treated stone after drying.

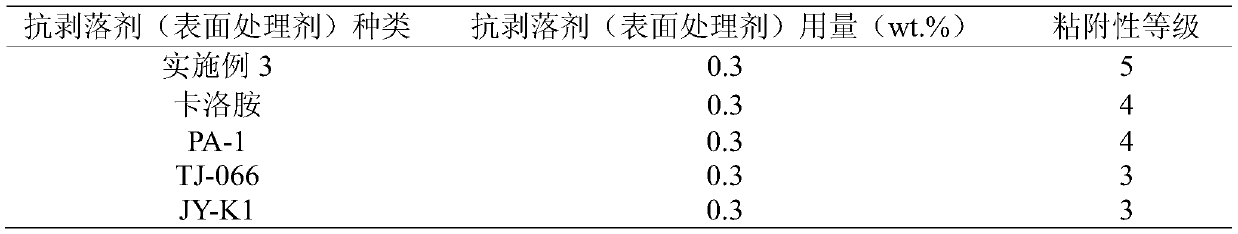

[0040] The adhesion between stone and asphalt was tested by water boiling method, and the test results are shown in Table 1. The water b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com