A method for preparing silicon carbide chemical mechanical polishing fluid with improved pH stability

A chemical machinery and polishing liquid technology, applied in polishing compositions containing abrasives, etc., can solve the problems of uncontrolled pH value, low polishing efficiency of silicon carbide, low abrasive hardness, etc., to reduce hard agglomeration and enhance uniform dispersion. Properties and stability, dispersion stability, uniform dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Embodiment 1: Preparation method of silicon carbide chemical mechanical polishing fluid with stable pH value

[0056] A preparation method of a silicon carbide chemical mechanical polishing fluid with stable pH value, the preparation method comprising the following steps:

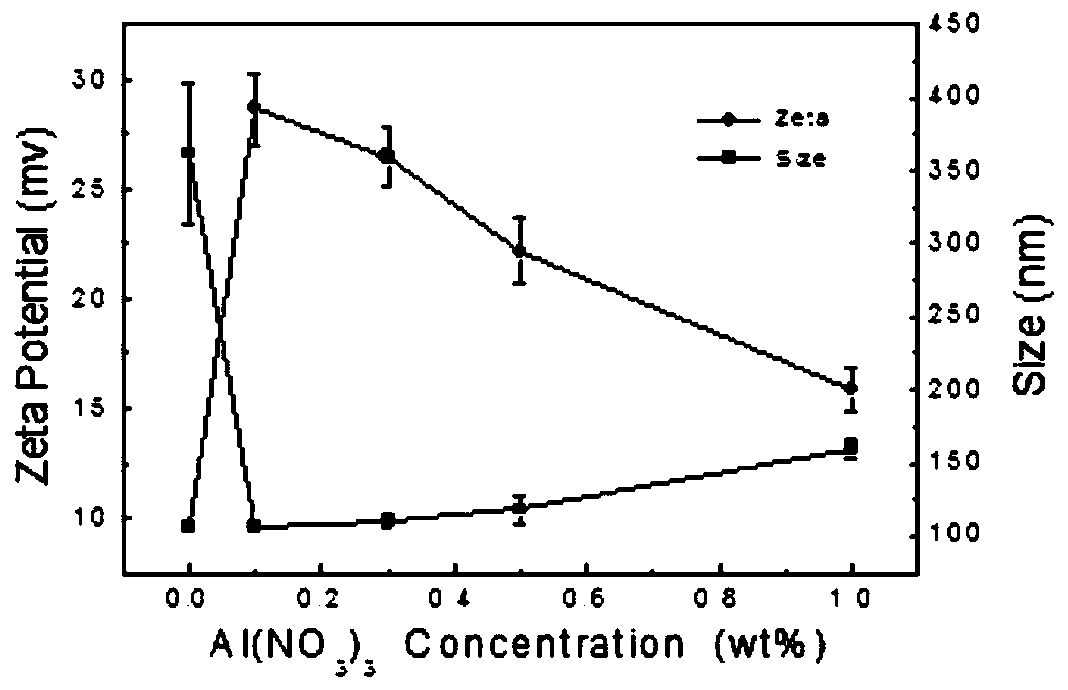

[0057] (1) Provide an acidic alumina dispersion: disperse 15 grams of alumina powder with a particle size of 100 nm in 100 ml of water, adjust the pH value to 0 to 1 with nitric acid, and grind for 4 to 6 hours with a star ball mill to obtain Acidic alumina dispersion with a pH value of 3.5;

[0058] (2) Surface modification: Add 0.5% of surface modifier organic acid (based on the weight of alumina) to 100ml of the above-mentioned acidic alumina dispersion, and continue to disperse with a ball mill to obtain a surface-modified acidic alumina dispersion;

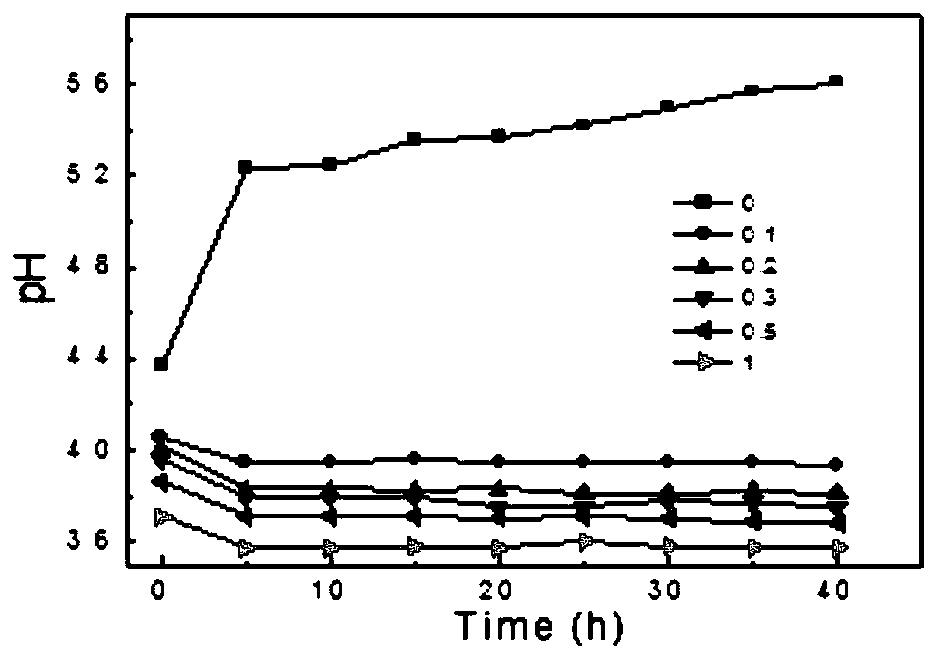

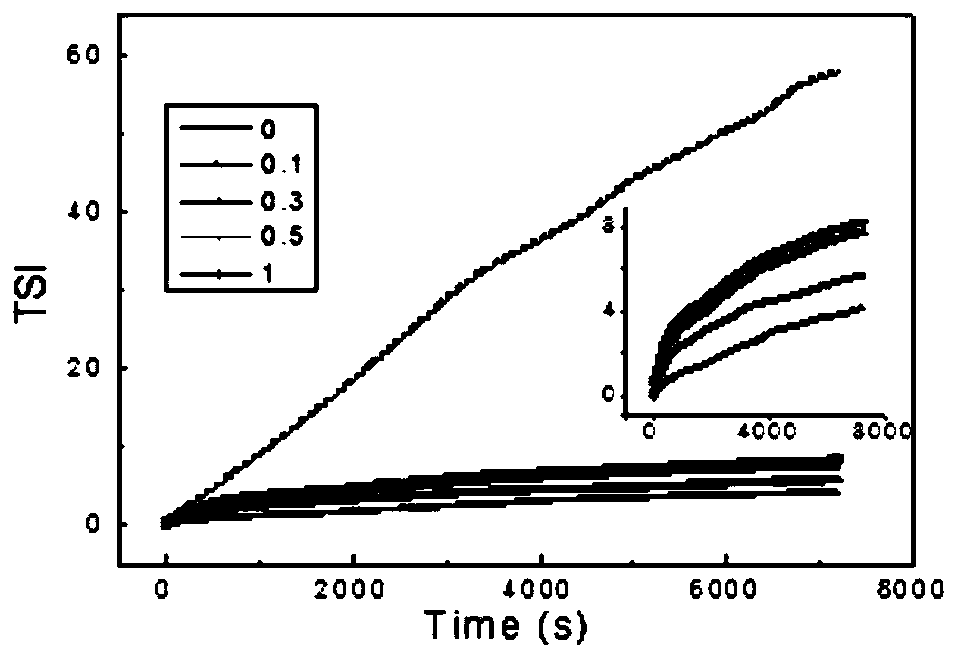

[0059] (3) Dilute the surface-modified alumina dispersion to 0.5-2%, add nitric acid to adjust the pH to 3.5-4, add 0.05% of a pH stabilizer alumi...

Embodiment 2

[0061] Embodiment 2: Preparation method of silicon carbide chemical mechanical polishing fluid with stable pH value

[0062] A preparation method of a silicon carbide chemical mechanical polishing fluid with stable pH value, the preparation method comprising the following steps:

[0063] (1) Provide an acidic alumina dispersion: disperse 25 grams of alumina powder with a particle size of 100 nm in 100 ml of water, adjust the pH value to 0 to 1 with nitric acid, and grind for 4 to 6 hours with a star ball mill to obtain Acidic alumina dispersion with a pH value of 4.0;

[0064] (2) Surface modification: Add 2.0% of surface modifier organic acid (based on the weight of alumina) to 100ml of the above-mentioned acidic alumina dispersion, and continue to disperse with a ball mill to obtain a surface-modified acidic alumina dispersion;

[0065] (3) Dilute the surface-modified alumina dispersion to 0.5-2%, add nitric acid to adjust the pH to 3.5-4, add 1.0% of pH stabilizer aluminum...

Embodiment 3

[0067] Embodiment 3: Preparation method of silicon carbide chemical mechanical polishing fluid with stable pH value

[0068] A preparation method of a silicon carbide chemical mechanical polishing fluid with stable pH value, the preparation method comprising the following steps:

[0069] (1) Provide an acidic alumina dispersion: disperse 20 grams of alumina powder with a particle size of 100 nm in 100 ml of water, adjust the pH value to 0 to 1 with nitric acid, and grind for 4 to 6 hours with a star ball mill to obtain Acidic alumina dispersion with a pH value of 3.8;

[0070] (2) Surface modification: Add 1.0% of surface modifier organic acid (based on the weight of alumina) to 100ml of the above-mentioned acidic alumina dispersion, and continue to disperse with a ball mill to obtain a surface-modified acidic alumina dispersion;

[0071] (3) Dilute the surface-modified alumina dispersion to 0.5-2%, add nitric acid to adjust the pH to 3.5-4, add 0.08% of pH stabilizer aluminu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com