Industrial production method of insecticidal beauveria bassiana bacterium powder

A production method and technology for Beauveria bassiana, applied in the directions of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of inability to form large-scale production, backward production methods, unstable quality, etc., and improve the germination rate. , the quality is stable, the effect of improving the germination rate of spores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

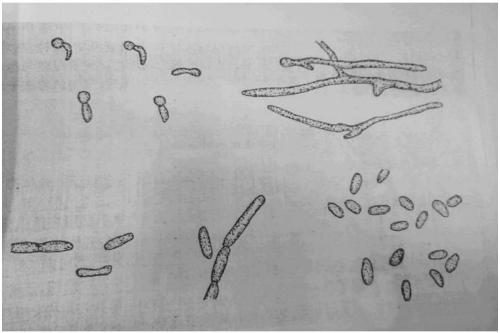

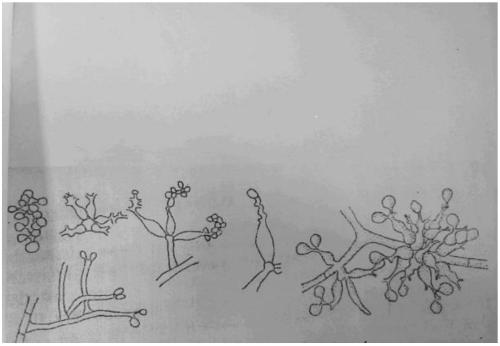

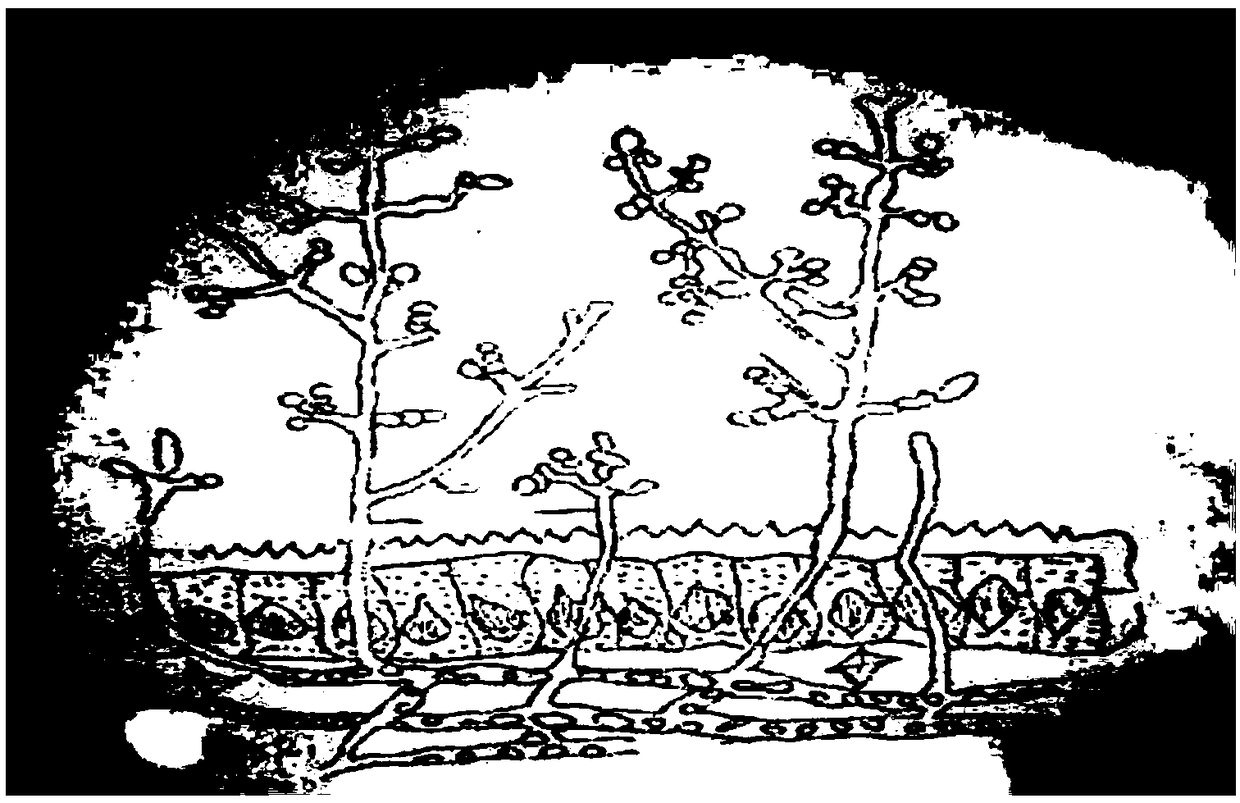

Image

Examples

Embodiment 1

[0026] An industrial production method for insecticidal Beauveria bassiana bacteria powder, which uses a culture medium for insecticidal Beauveria bassiana bacteria powder, which includes slant medium, secondary liquid expansion medium, and three-level solid expansion culture base; the composition of the slant culture medium is respectively in weight percentage: 20% of potato, white granulated sugar 1%, agar 1%, water 78%; the composition of described secondary liquid expansion medium is in weight percentage respectively It is: 1% soybean flour, 1% corn flour, 1% white granulated sugar, 0.02% urea, 0.02% peptone, 0.02% potassium dihydrogen phosphate, and 96.94% water; They are: 60% of wheat bran and 40% of rice husk; the particle size of the soybean flour and corn flour is 300-500 mesh; the potato is prepared by peeling the potato, then slicing and boiling for 30 minutes, and then filtering to obtain;

[0027] Specifically include the following steps:

[0028] Step 1, slant s...

Embodiment 2

[0033] An industrial production method for insecticidal Beauveria bassiana bacteria powder, which uses a culture medium for insecticidal Beauveria bassiana bacteria powder, which includes slant medium, secondary liquid expansion medium, and three-level solid expansion culture base; the components of the slant culture medium are respectively in weight percentage: 25% of potatoes, 3% of white granulated sugar, 3% of agar, and 69% of water; It is: 3% soybean flour, 3% corn flour, 3% white granulated sugar, 0.1% urea, 0.08% peptone, 0.06% potassium dihydrogen phosphate, and 90.76% water; They are: 70% of wheat bran and 30% of rice husk; the particle size of the soybean flour and corn flour is 300-500 mesh; the potato is prepared by peeling the potato, then slicing and boiling for 30 minutes, and then filtering to obtain;

[0034] Specifically include the following steps:

[0035] Step 1, slant strain culture: take potato, white sugar, agar, and water to mix in proportion to prepa...

Embodiment 3

[0040] An industrial production method for insecticidal Beauveria bassiana bacteria powder, which uses a culture medium for insecticidal Beauveria bassiana bacteria powder, which includes slant medium, secondary liquid expansion medium, and three-level solid expansion culture base; the composition of the slant culture medium is respectively in weight percentage: 22% of potato, white granulated sugar 2%, agar 2%, water 74%; the composition of described secondary liquid expansion medium is in weight percentage respectively It is: 2% soybean flour, 2% corn flour, 2% white granulated sugar, 0.08% urea, 0.05% peptone, 0.04% potassium dihydrogen phosphate, and 93.83% water; They are: 65% of wheat bran and 35% of rice husk; the particle size of the soybean flour and corn flour is 300-500 mesh; the potato is prepared by peeling the potato first, then slicing and boiling for 30 minutes, and then filtering to obtain;

[0041] Specifically include the following steps:

[0042] Step 1, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com