Easy-to-dye regenerative cellulose fibers and preparation method thereof

A regenerated cellulose and fiber technology, applied in the textile field, can solve the problems of low dry strength of regenerated cellulose fiber, high production cost of color-absorbing sheets, and unsatisfactory color-absorbing effect, etc., and achieves small fiber damage, increased quantity, The effect of thorough modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] An easy-to-dye regenerated cellulose fiber, comprising a penetrating agent, a small-molecular cationic modifier, a macromolecular cationic modifier, caustic soda and regenerated cellulose fiber. The composition ratio of the above-mentioned raw materials is: penetrating agent 0.1% (owf), Small molecule cationic modifier 5% (owf), macromolecule cationic modifier 5% (owf), caustic soda 14.5% (owf).

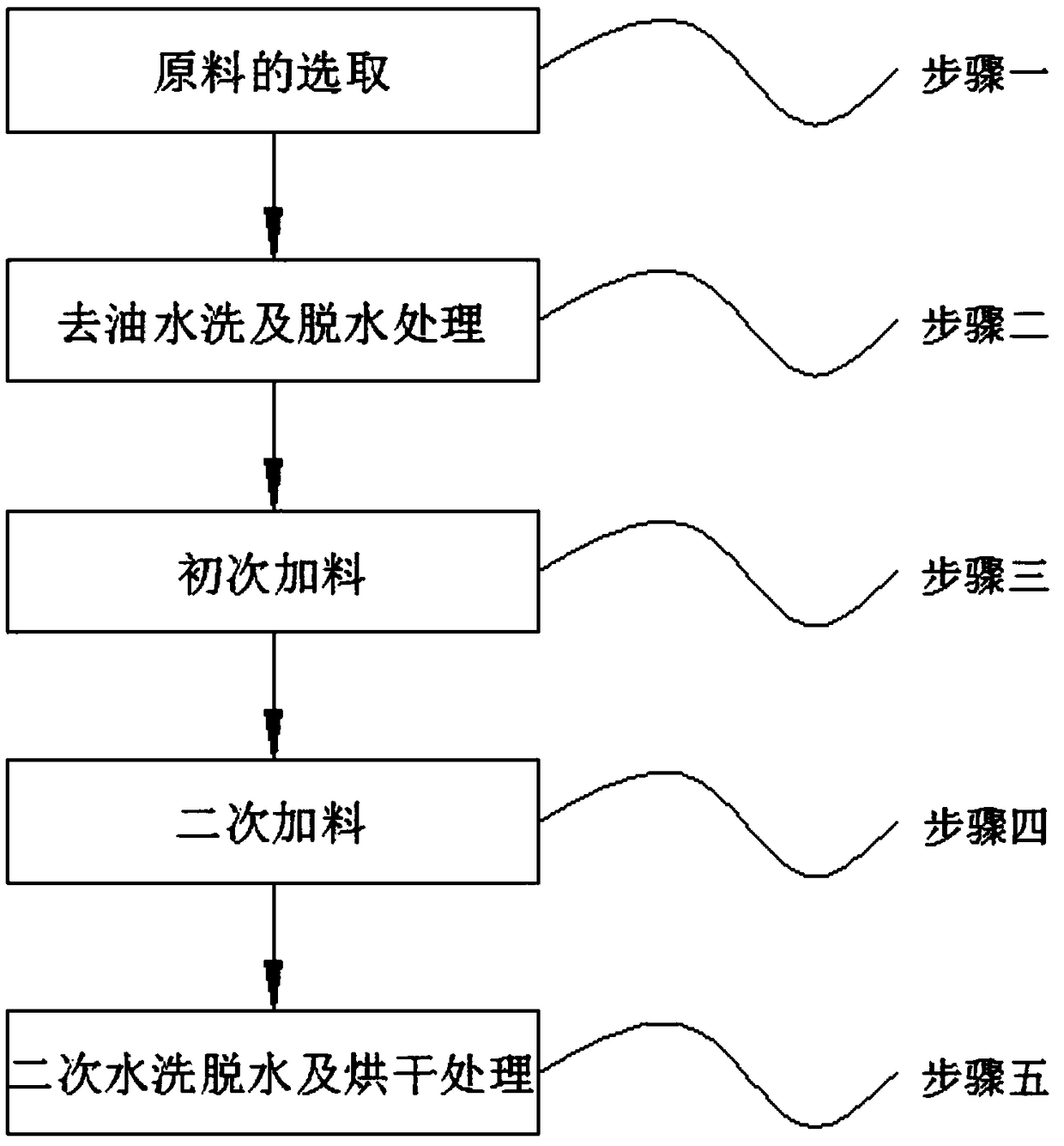

[0038] A kind of its preparation method of dyeable regenerated cellulose fiber, comprises the following steps: step 1, raw material selection; Secondary water washing, dehydration and drying treatment;

[0039] Wherein in above-mentioned step 1, select penetrant, small molecule cationic modifier, macromolecular cationic modifier, caustic soda and regenerated cellulose fiber as raw material, according to penetrant 0.1% (owf), small molecule cationic modifier 5% (owf), macromolecule cationic modifier 5% (owf), and caustic soda 14.5% (owf) are weighed in proportion and stored se...

Embodiment 2

[0046] An easy-to-dye regenerated cellulose fiber, comprising penetrating agent, small molecule cationic modifier, macromolecular cationic modifier, caustic soda and regenerated cellulose fiber, the composition ratio of the above-mentioned raw materials is, penetrant 0.1% (owf), Small molecule cationic modifier 15% (owf), macromolecule cationic modifier 4% (owf), caustic soda 10.9% (owf).

[0047] A kind of its preparation method of dyeable regenerated cellulose fiber, comprises the following steps: step 1, raw material selection; Secondary water washing, dehydration and drying treatment;

[0048] Wherein in above-mentioned step 1, select penetrant, small molecule cationic modifier, macromolecular cationic modifier, caustic soda and regenerated cellulose fiber as raw material, according to penetrant 0.1% (owf), small molecule cationic modifier 15% (owf), macromolecular cation modifier 4% (owf), and caustic soda 10.9% (owf) are weighed in proportion and stored separately;

[...

Embodiment 3

[0055] An easy-to-dye regenerated cellulose fiber, comprising penetrating agent, small molecule cationic modifier, macromolecular cationic modifier, caustic soda and regenerated cellulose fiber, the composition ratio of the above-mentioned raw materials is, penetrant 0.15% (owf), Small molecule cationic modifier 25% (owf), macromolecule cationic modifier 20% (owf), caustic soda 11.9% (owf).

[0056] A kind of its preparation method of dyeable regenerated cellulose fiber, comprises the following steps: step 1, raw material selection; Secondary water washing, dehydration and drying treatment;

[0057] Wherein in above-mentioned step one, select penetrant, small molecule cationic modifier, macromolecular cationic modifier, caustic soda and regenerated cellulose fiber as raw material, according to penetrant 0.15% (owf), small molecule cationic modifier 25% (owf), macromolecular cationic modifier 20% (owf), and caustic soda 11.9% (owf) are weighed in proportion and stored separate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com