Preparation method and application of coating agent for waterproof moisture-permeable cotton fabric

A technology of waterproof and moisture-permeable, coating agent, applied in textiles and papermaking, etc., can solve the problems of imperfect waterproof and moisture-permeable, and achieve the effect of strong market promotion prospect and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

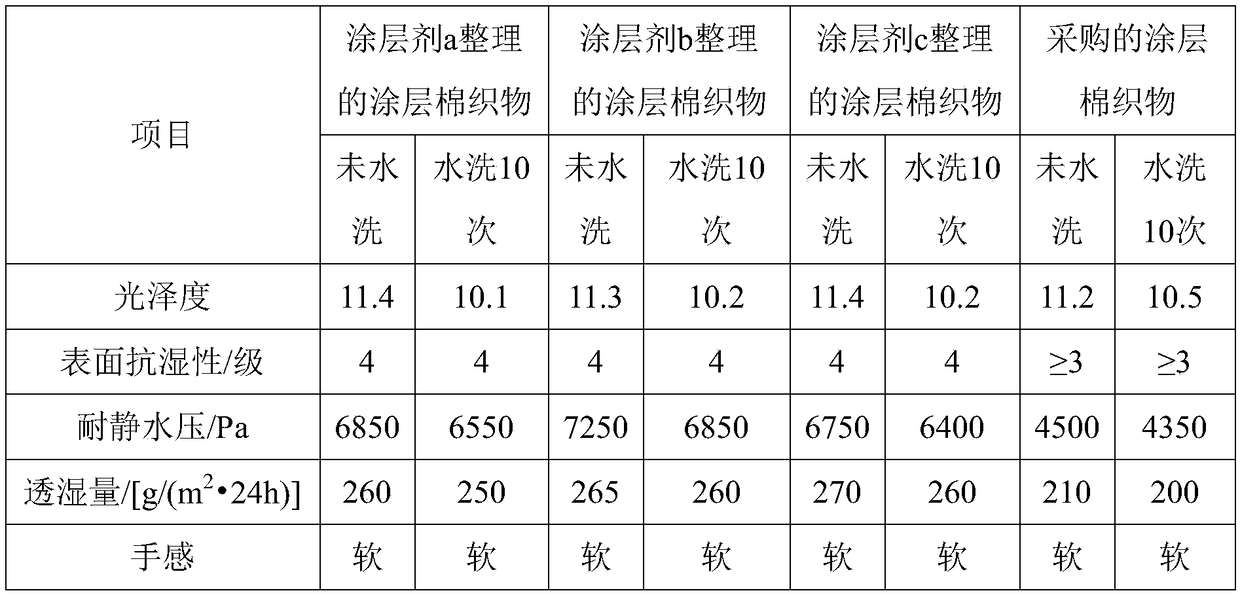

Examples

Embodiment 1

[0019] In this embodiment, a waterproof and moisture-permeable cotton fabric coating agent is prepared by the following method, including the following steps:

[0020] (1) Preparation of oil-in-water emulsion: swell 5 g of cellulose in glacial acetic acid for 2 hours, then dissolve it in a mixed solution of 30 mL of acetic anhydride and 30 mL of acetic acid, and add sulfuric acid to the system dropwise. The amount of sulfuric acid is 1.0% of the total volume of acetic anhydride and acetic acid, react at 55°C for 2h. After the reaction, neutralize the sulfuric acid in the system to pH 7.6 with sodium hydroxide, and then pour the above reactants into distilled water to precipitate cellulose acetate Finally, the obtained cellulose acetate was centrifuged and rinsed to neutrality several times, and then dried in vacuum; the obtained 5g dried cellulose acetate was dissolved in 50mL of dichloromethane to obtain a clear and transparent solution, and 0.5g of Span 80 was added to the above...

Embodiment 2

[0026] In this embodiment, a waterproof and moisture-permeable cotton fabric coating agent is prepared by the following method, including the following steps:

[0027] (1) Preparation of oil-in-water emulsion: swell 5 g of cellulose in glacial acetic acid for 3 hours, then dissolve it in a mixed solution of 40 mL of acetic anhydride and 45 mL of acetic acid, and add sulfuric acid to the system dropwise. The amount of sulfuric acid is 1.2% of the total volume of acetic anhydride and acetic acid, react at 55°C for 2h. After the reaction, neutralize the sulfuric acid in the system to pH 7.6 with sodium hydroxide, and then pour the above reactants into distilled water to precipitate cellulose acetate Finally, the obtained cellulose acetate was centrifuged and rinsed to neutrality several times, and then dried under vacuum; the obtained 5g dry cellulose acetate was dissolved in 50mL dichloromethane to obtain a clear and transparent solution, and 0.6g Span 80 was added to the above solu...

Embodiment 3

[0033] In this embodiment, a waterproof and moisture-permeable cotton fabric coating agent is prepared by the following method, including the following steps:

[0034] (1) Preparation of oil-in-water emulsion: swell 5 g of cellulose in glacial acetic acid for 4 hours, then dissolve it in a mixed solution of 30 mL of acetic anhydride and 30 mL of acetic acid, and add sulfuric acid dropwise to the system. The amount of sulfuric acid is 1.5% of the total volume of acetic anhydride and acetic acid, react at 55°C for 2h. After the reaction, neutralize the sulfuric acid in the system to pH 7.6 with sodium hydroxide, and then pour the above reactants into distilled water to precipitate cellulose acetate Finally, the obtained cellulose acetate was centrifuged and rinsed to neutrality several times, and then dried under vacuum; the obtained 5g of dried cellulose acetate was dissolved in 50mL of dichloromethane to obtain a clear and transparent solution, and 0.7g of Span 80 was added to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Moisture permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com