Pile machine equipment of large-diameter rotary jetting pile and construction method

The technology of pile driver equipment and rotary jetting pile is applied in the field of pile driver equipment and construction of large-diameter rotary jetting piles. , Strong drilling ability, the effect of expanding the diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

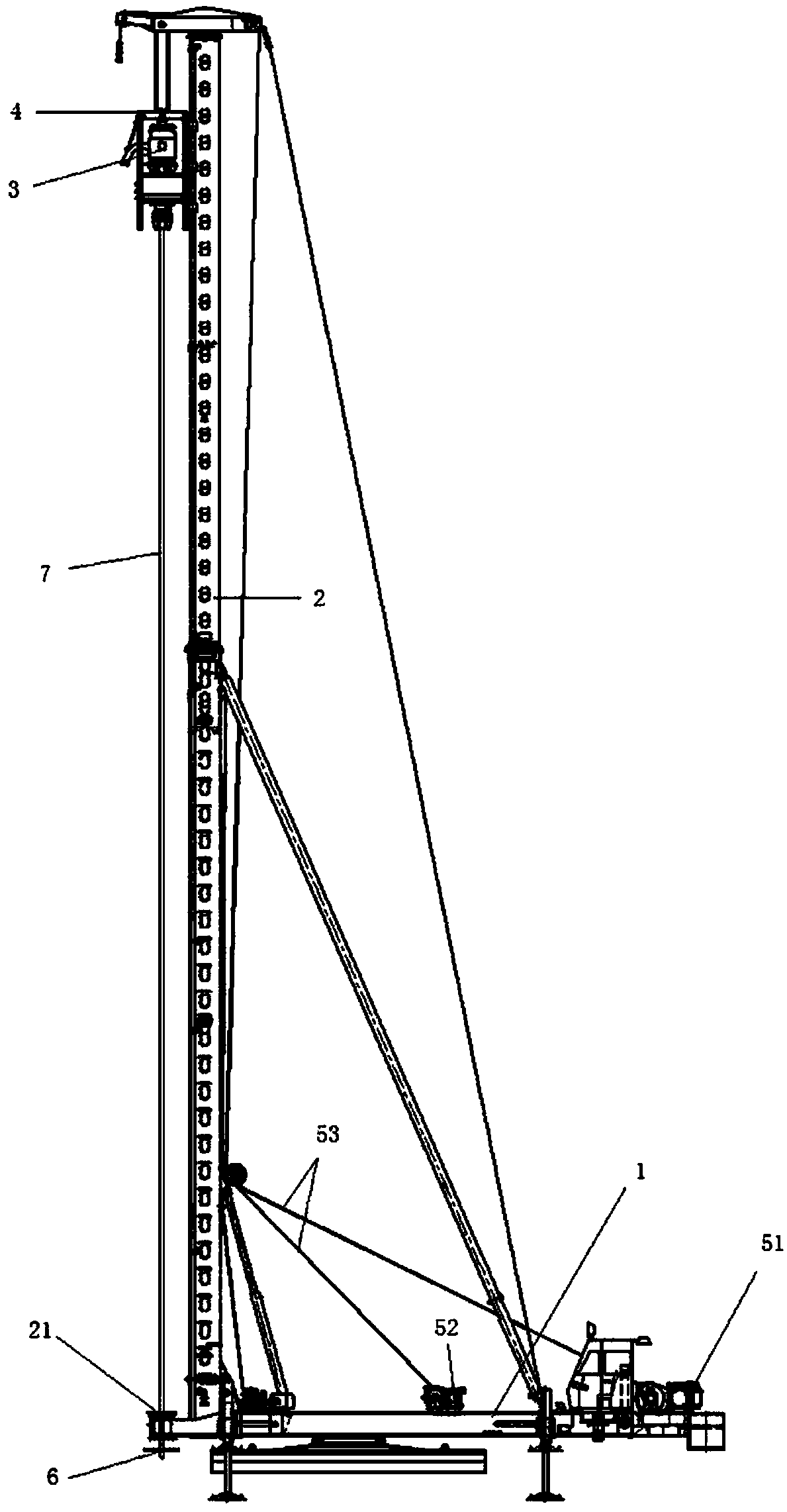

[0042] The invention discloses a pile driver equipment for a large-diameter rotary grouting pile, such as figure 1 As shown, it includes a base 1, a tower frame 2, a drill pipe 7, a power head 3 of the drill pipe 7, a power frame 4 for placing the power head, and a winch located on the base 1;

[0043] The power head is arranged in the power frame 4, and the power frame 4 is connected with the hoist through a wire rope 53; wherein, the power head is provided with one or more frequency conversion motors for driving the drill pipe 7 to rotate, so that it can be adjusted according to formation changes. The drill rod 7 rotates at a high speed, so that a small power can be used to obtain a large torque. Specifically, in a specific embodiment, two variable frequency motors are preferably installed in the power head, the power of the variable frequency motors is 45kW, and the variable frequency motors are controlled by an intelligent control system, and the current value and speed of...

Embodiment 2

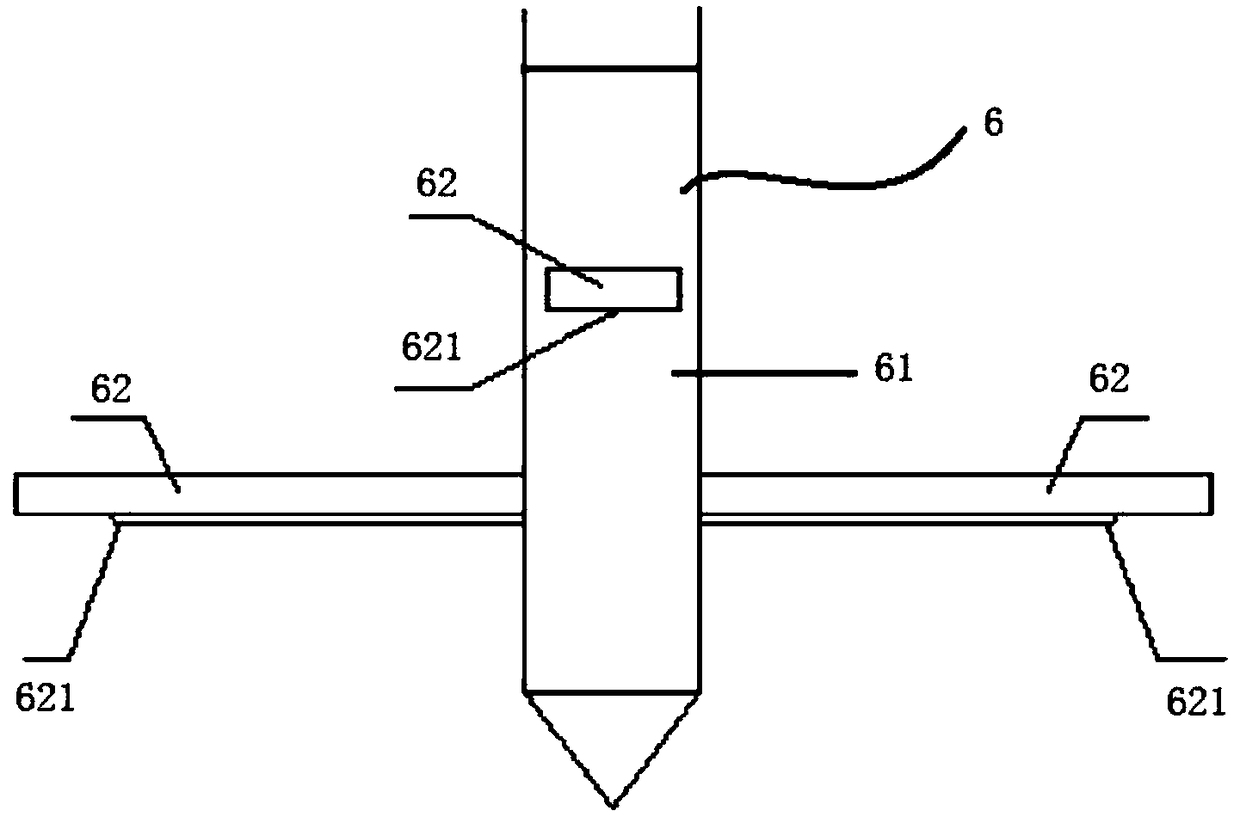

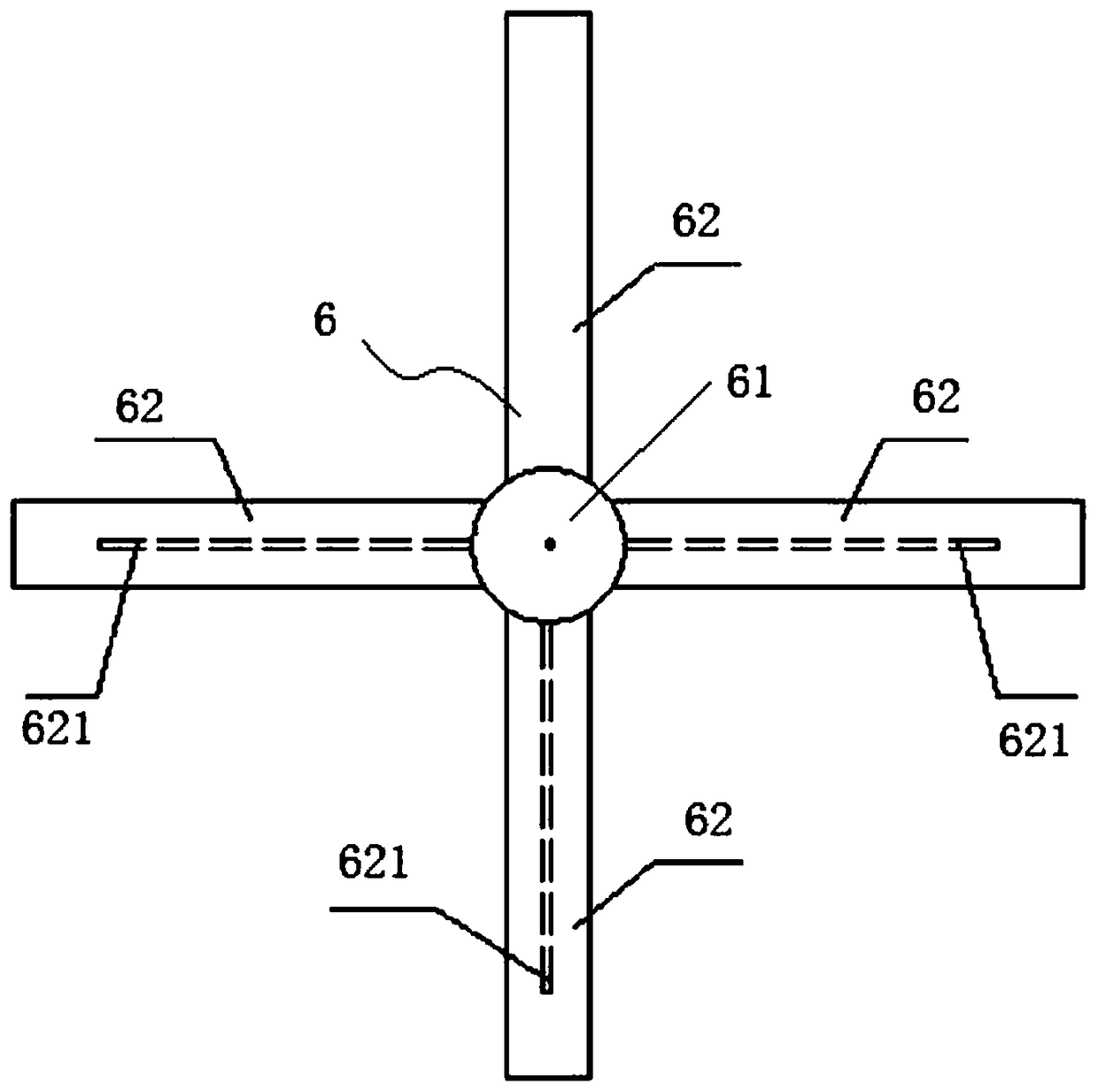

[0052]In this embodiment, there is a difference between the following structure of this embodiment and Embodiment 1: there are three blades 62 in this embodiment, and the three blades 62 are all located on the same horizontal plane, and the angle between them is 120°. The lower bottom surface of each blade 62 is provided with a swirl jet outlet 621 close to the section.

[0053] The invention also discloses a construction method of a large-diameter rotary grouting pile, using the above-mentioned pile driver equipment, including the following steps:

[0054] S1: Read the current value Iz of the host, where the host refers to the motor or variable frequency motor in the power head;

[0055] According to the theoretical model, it can be seen that the current value Iz is related to the rotational speed V1 of the drill pipe, the linear velocity V2 of the vertical movement of the drill pipe and the rotational reaction torque M1, that is:

[0056] Iz=f(V1, V2, M1);

[0057] At the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com