Flexible super-A-class aluminum alloy core in-vehicle high-voltage cable for new energy automobile

A new energy vehicle, aluminum alloy technology, applied in the direction of power cables, insulated cables, bendable cables, etc., can solve problems that affect production efficiency, are not easy to bend, cannot be installed, etc., achieve excellent fire performance, reduce weight, and fire performance Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

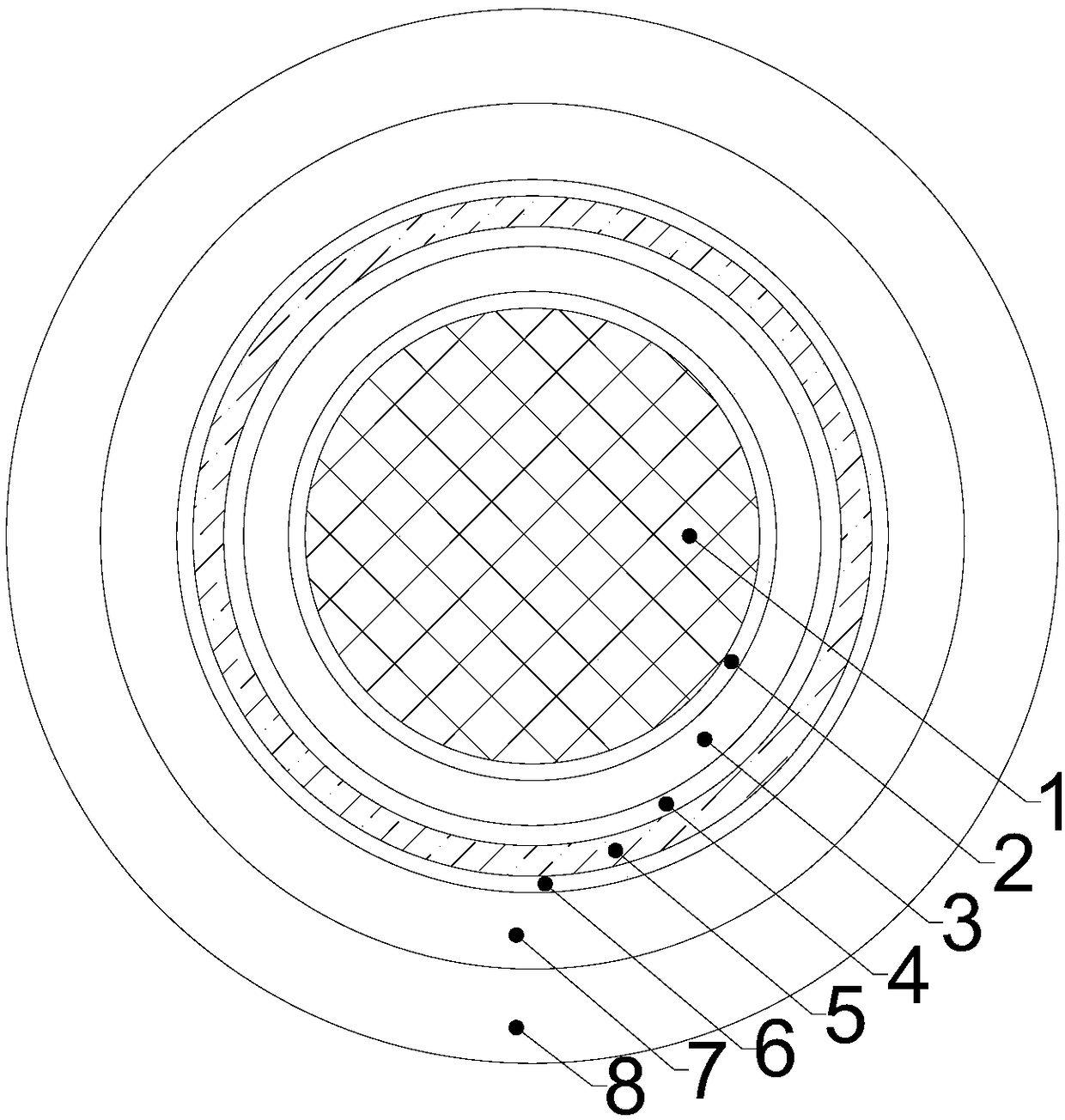

[0018] The following is attached figure 1 The given examples further illustrate the specific implementation of the flexible super-A aluminum alloy core new energy vehicle interior high-voltage cable of the present invention. The in-vehicle high-voltage cable for a new energy vehicle with a flexible super-A aluminum alloy core of the present invention is not limited to the description of the following embodiments.

[0019] The flexible ultra-A aluminum alloy core high-voltage cable for new energy vehicles of the present invention includes an aluminum alloy conductor 1, a first wrapping release paper layer 2 wrapped outside the aluminum alloy conductor 1, and a tensile and tear-resistant silicone rubber. Insulating layer 3, aluminum-plastic composite tape shielding layer 4, tinned copper wire braiding layer 5, second wrapping release paper layer 6, ceramic silicone rubber inner sheath 7 and outer sheath 8, the outer sheath 8 is glass fiber Yarn + silicon carbon composite coatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com