Filter capable of reducing cigarette smoke temperature and manufacturing method thereof

A technology of flue gas temperature and production method, which is applied in the direction of smoke oil filter element, tobacco, application, etc., to achieve the effects of reasonable price, convenient operation and simple production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

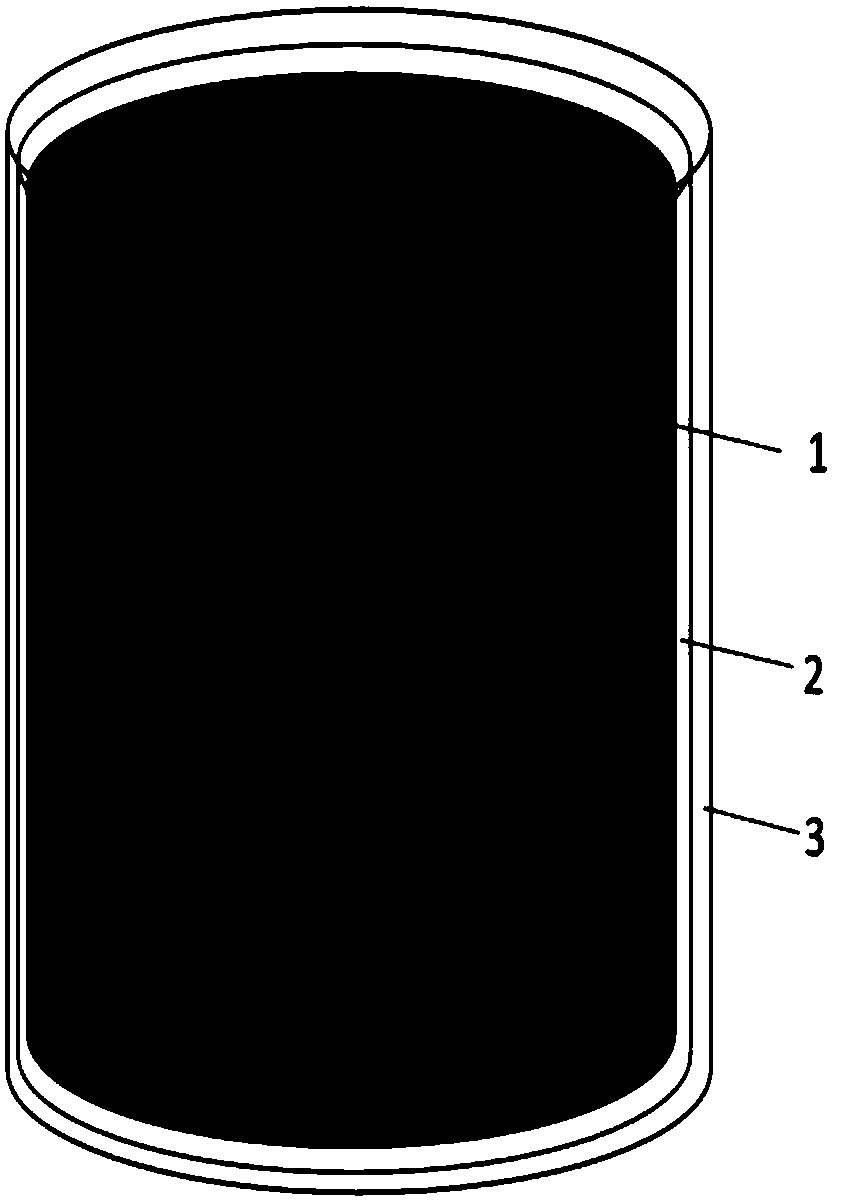

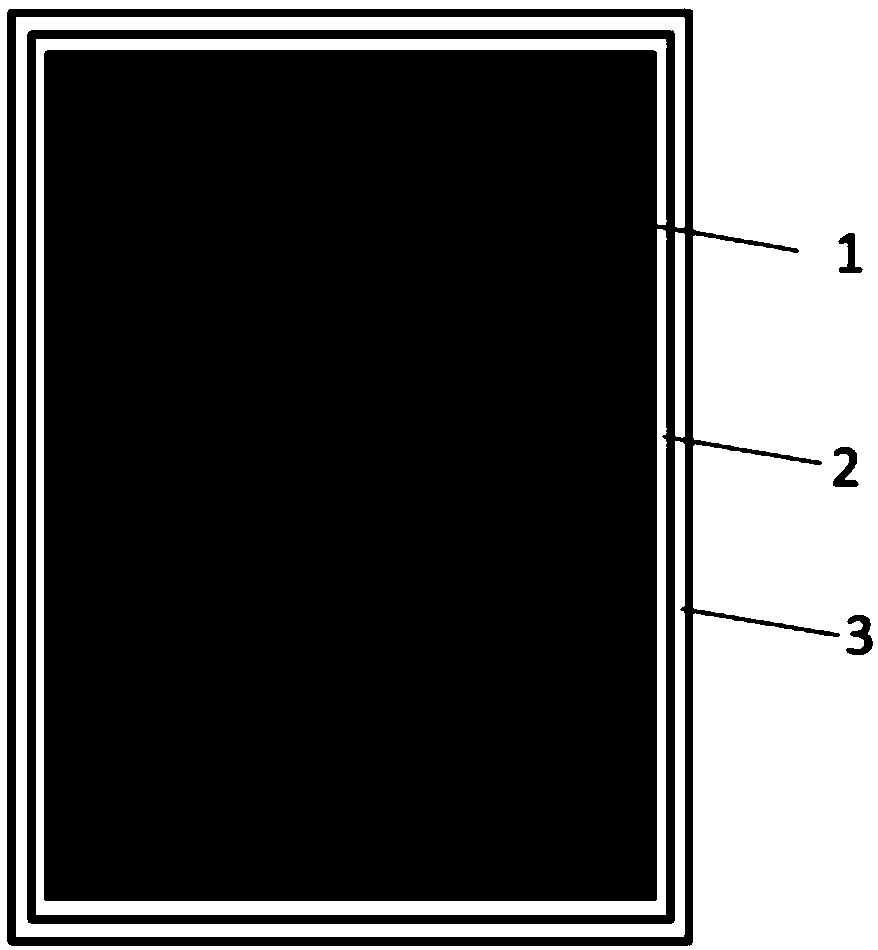

[0036] The structure of the filter tip that can reduce the temperature of cigarette smoke in this embodiment is as follows: figure 1 and figure 2 As shown, the overall filter tip is cylindrical, with a diameter of 5.5 mm and a length of 19 mm. The filter tip includes an inner core 1 and a protective film. Both the inner core and the protective film are cylindrical, the protective film is a double-layer structure, the inner film 2 is a brittle film, and the outer film 3 is a flexible porous film. The two ports of the inner film and the outer film are sealed, the outer film wraps the inner film, and the inner film wraps the inner core.

[0037] The above-mentioned manufacturing method of the filter tip capable of reducing the temperature of cigarette smoke is as follows:

[0038] 1. Absorb 20mg of sodium polyacrylate (CAS: 9003-04-7) particles with 0.5g of water, add polyvinyl alcohol and mix evenly, extrude to make a cylindrical inner core.

[0039] 2. Add gelatin, carragee...

Embodiment 2

[0043] The filter tip capable of reducing the temperature of cigarette smoke in this embodiment is generally cylindrical, with a diameter of 5.5 mm and a length of 19 mm. The filter tip includes an inner core and a protective film. Both the inner core and the protective film are cylindrical, and the protective film has a double-layer structure, the inner film is a brittle film, and the outer film is a flexible porous film. The two ports of the inner film and the outer film are sealed, the outer film wraps the inner film, and the inner film wraps the inner core.

[0044] The above-mentioned filter tip manufacturing method that can reduce the temperature of cigarette smoke is as follows:

[0045] 1. Absorb 20mg of sodium polyacrylate-acrylamide copolymer (CAS: 9003-06-9) particles with 0.5g of water, add polyvinyl alcohol and mix evenly, extrude to make a cylindrical inner core;

[0046] 2. Mix epoxy resin (Huaou Chemical, E-51) and curing agent (triethylenetetramine) evenly at...

Embodiment 3

[0050] The filter tip capable of reducing the temperature of cigarette smoke in this embodiment is generally cylindrical, with a diameter of 5.5 mm and a length of 19 mm. The filter tip includes an inner core and a protective film. Both the inner core and the protective film are cylindrical, and the protective film has a double-layer structure, the inner film is a brittle film, and the outer film is a flexible porous film. The two ports of the inner film and the outer film are sealed, the outer film wraps the inner film, and the inner film wraps the inner core.

[0051] The above-mentioned filter tip manufacturing method that can reduce the temperature of cigarette smoke is as follows:

[0052]1. First add 30mg of sodium polyacrylate (CAS: 9003-04-7) and 0.5g Water, seal the glass shell with water-proof tape or heating to obtain the inner core wrapped with the inner film;

[0053] 3. Use a polycarbonate porous membrane (Merck Millipore, TCTP02500) to wrap the inner core wrap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com