Insulation protection method for electric propeller

A technology of electric propulsion and insulating coating, which is applied to special surfaces, pretreatment surfaces, and devices for coating liquids on surfaces, etc. It is easy to operate and realize, improve lifespan, and reduce development costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

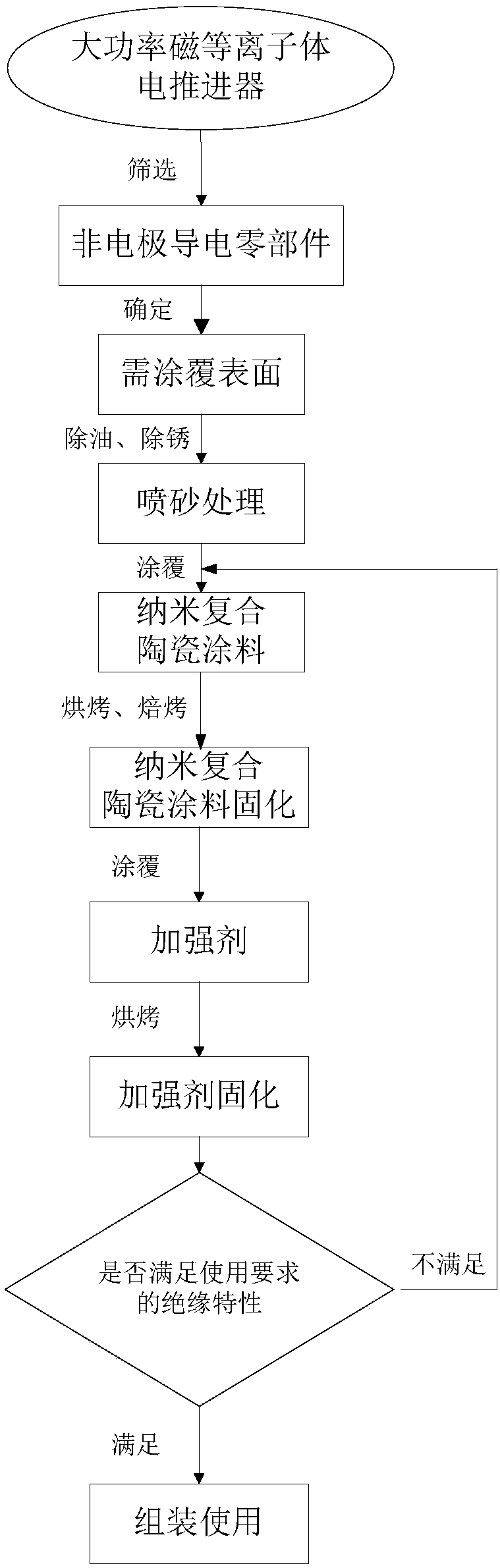

Method used

Image

Examples

Embodiment 1

[0067] (1) Degrease and derust the surface of the non-electrode conductive parts, and roughen the sandblasting, sandblasting Sa2.5 grade or above, using emery with a particle size of 40 mesh and 60 mesh in a mass ratio of 1:1 Matching sandblasting;

[0068] (2) Seal and roll the liquid nano-composite ceramic paint on the curing machine to the bottom of the bucket without precipitation, and filter it with an 80-mesh filter for subsequent use;

[0069] (3) The coating tools are first cleaned with absolute ethanol and then cleaned with water, and then dried with compressed air for later use;

[0070] (4) Place the non-electrode conductive parts to be coated in the oven, and use a coating tool to evenly coat the nanocomposite ceramic coating on the outer surface of the non-electrode conductive parts;

[0071] (5) After the surface of the coating is dry at room temperature, close the oven door, run the oven, and bake at 100°C for 30 minutes; then bake at 550°C for 2 hours, and clo...

Embodiment 2

[0074] (1) Degrease and derust the surface of the non-electrode conductive parts, and roughen the sandblasting, sandblasting Sa2.5 grade or above, using emery with a particle size of 40 mesh and 60 mesh in a mass ratio of 1:1 Matching sandblasting;

[0075] (2) Seal and stir the liquid nano-composite ceramic coating evenly without precipitation, and filter it with a 120-mesh filter for subsequent use;

[0076] (3) The coating tools are first cleaned with absolute ethanol and then cleaned with water, and then dried with compressed air for later use;

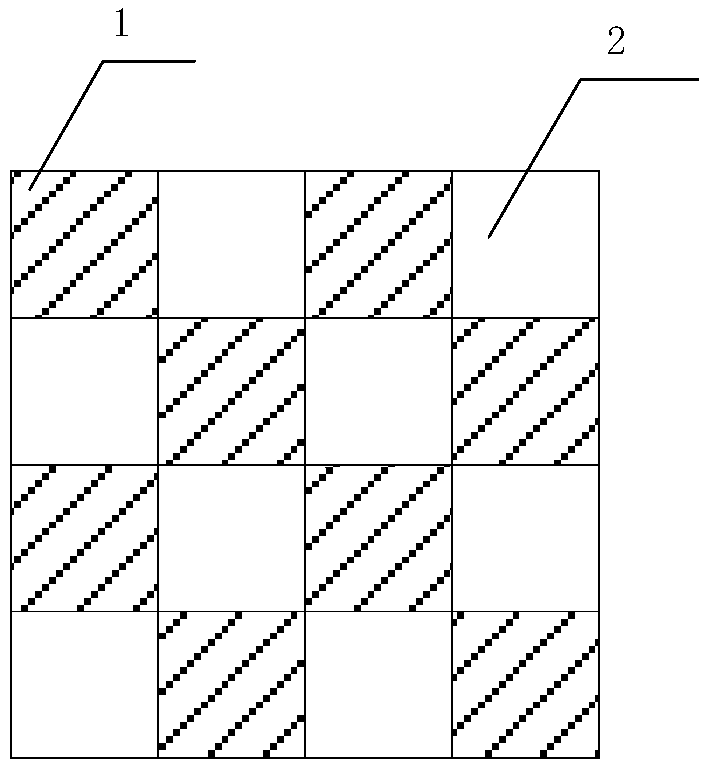

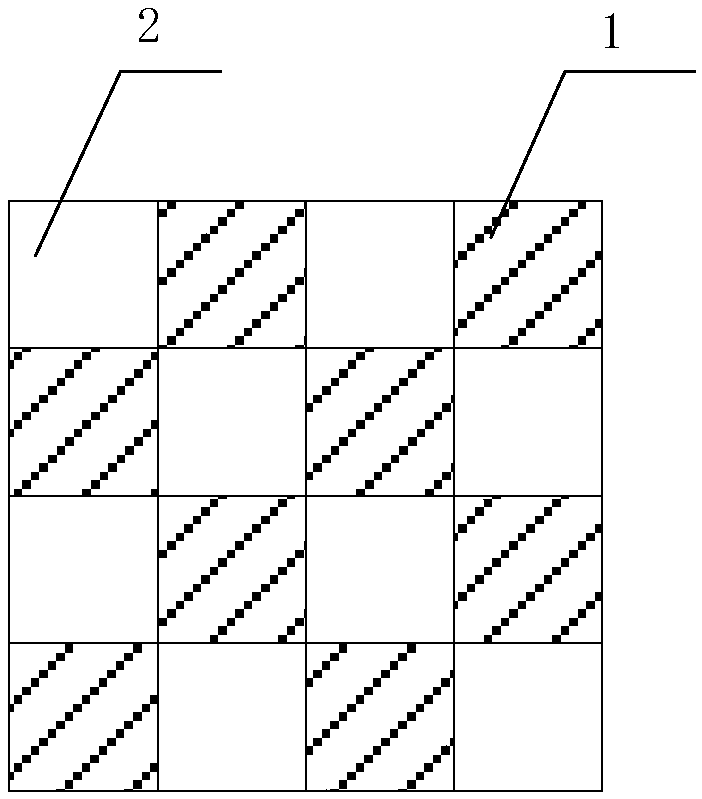

[0077] (4) Place the non-electrode conductive parts to be coated in the oven, place the first coating mold on the surface of the non-electrode conductive parts to be coated, and use a coating tool to evenly coat the nanocomposite ceramic coating on the External surfaces of non-electrode conductive parts;

[0078] (5) After the surface of the coating is dry at room temperature, close the oven door, run the oven, and bake at 130°C...

Embodiment 3

[0081] (1) Degrease and derust the surface of the non-electrode conductive parts, and roughen the sandblasting, sandblasting Sa2.5 grade or above, using emery with a particle size of 40 mesh and 60 mesh in a mass ratio of 1:1 Matching sandblasting;

[0082] (2) Seal and roll the liquid nano-composite ceramic paint on the curing machine to the bottom of the barrel without precipitation, and filter it with a 100-mesh filter for subsequent use;

[0083] (3) The coating tools are first cleaned with absolute ethanol and then cleaned with water, and then dried with compressed air for later use;

[0084] (4) Place the non-electrode conductive parts to be coated in the oven, place the first coating mold on the surface of the non-electrode conductive parts to be coated, and use a coating tool to evenly coat the nanocomposite ceramic coating on the External surfaces of non-electrode conductive parts;

[0085] (5) After the surface of the coating is dry at room temperature, bake at 115...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com