Super large dimension soft gas storing storage and method

An ultra-large-scale, gas storage technology, applied in the field of gas storage, can solve the problems of cost reduction, limited steel structure span, low temperature operation cost, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

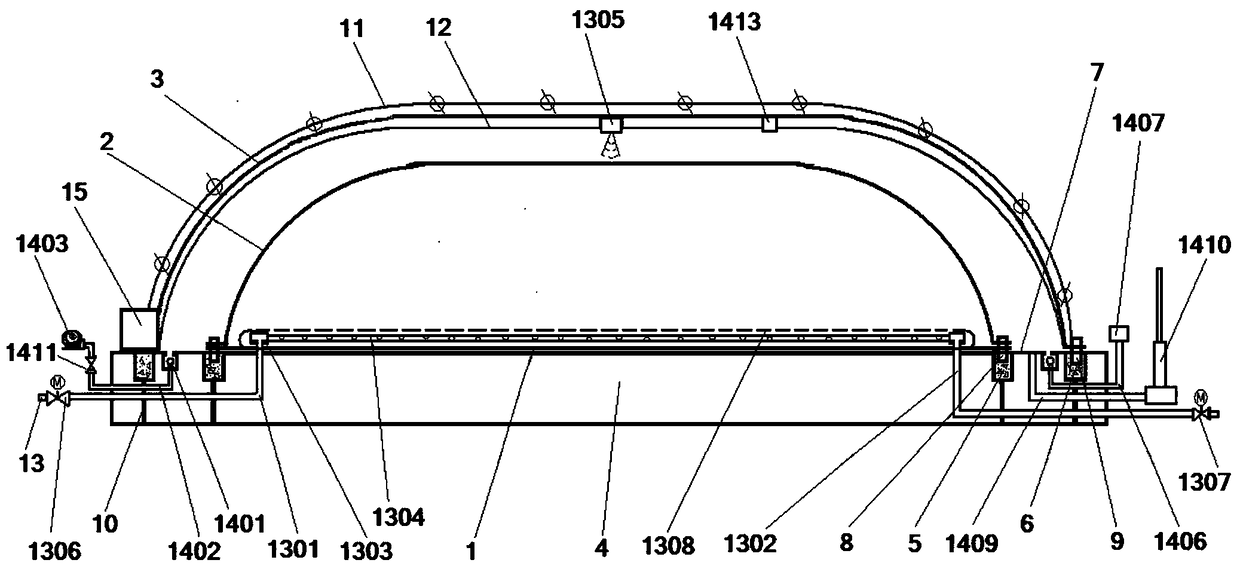

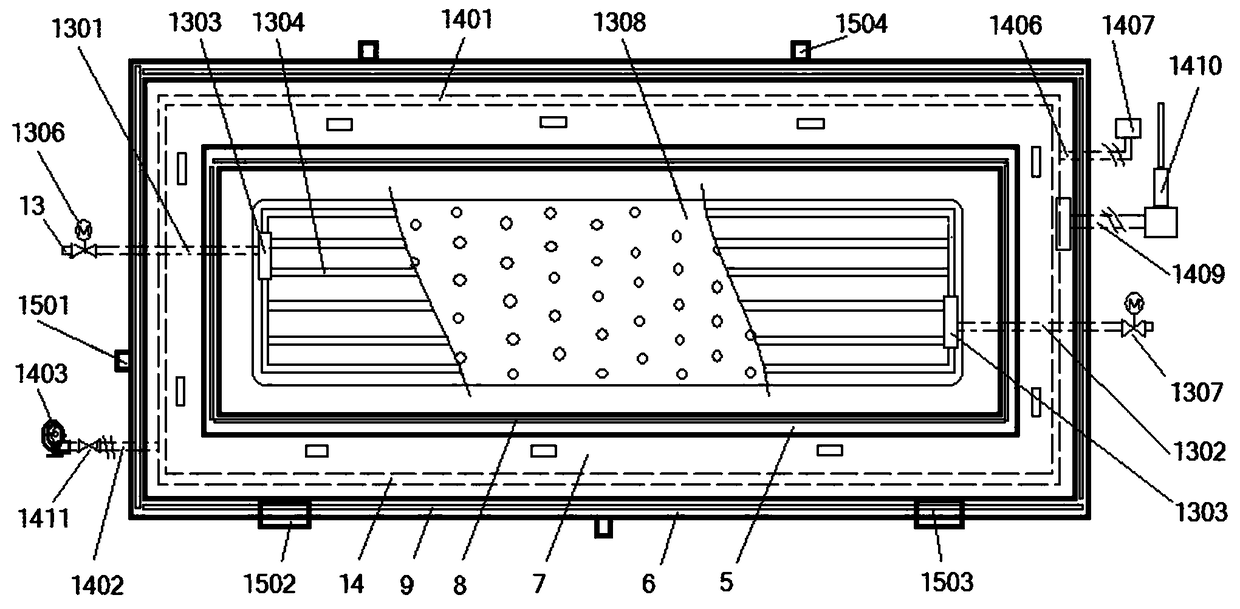

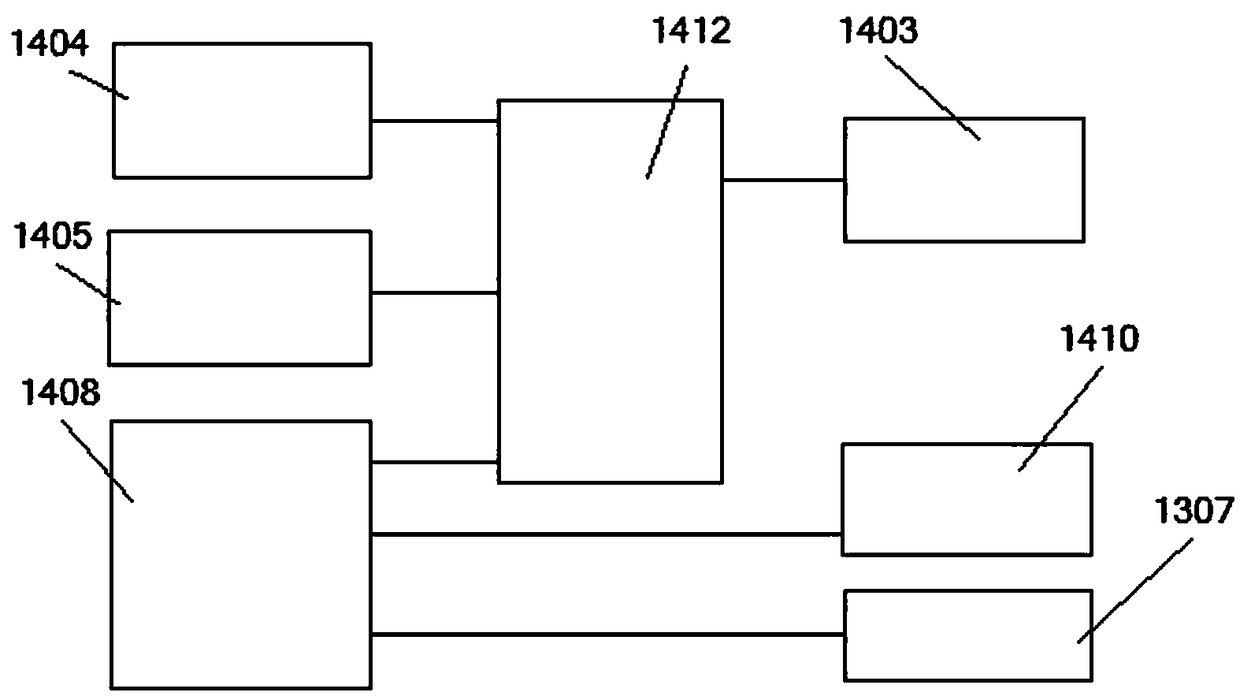

[0033] Such as figure 1 with 2A super-sized flexible gas storage is shown, including a bottom membrane 1, an inner membrane 2, and an outer membrane 3. The bottom membrane 1 and the inner membrane 2 that can float up and down form a gas storage chamber, and the outer membrane 3 is covered by the inner membrane. 2, it also includes a gas storage base 4, an air inlet and outlet pipeline system 13, and an air supply and pressure relief system 14;

[0034] The gas storage foundation 4 is located at the bottom of the super-large flexible gas storage. The gas storage foundation 4 is provided with an inner ring beam foundation 5, an outer ring beam foundation 6, and an annular channel 7. The inner ring beam foundation 5 is provided with an inner seal fixing Component 8, the lower edge of the inner membrane 2 overlaps with the edge of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com