Automatic control system for combined purification process of rectification residual liquid and process wastewater

An automatic control system and control system technology, applied in the control/manipulation system, water treatment parameter control, water pollutants and other directions, can solve the problems of high energy consumption, poor purification effect, low treatment efficiency, etc., to achieve low energy consumption, The effect of eliminating instability and optimizing the processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

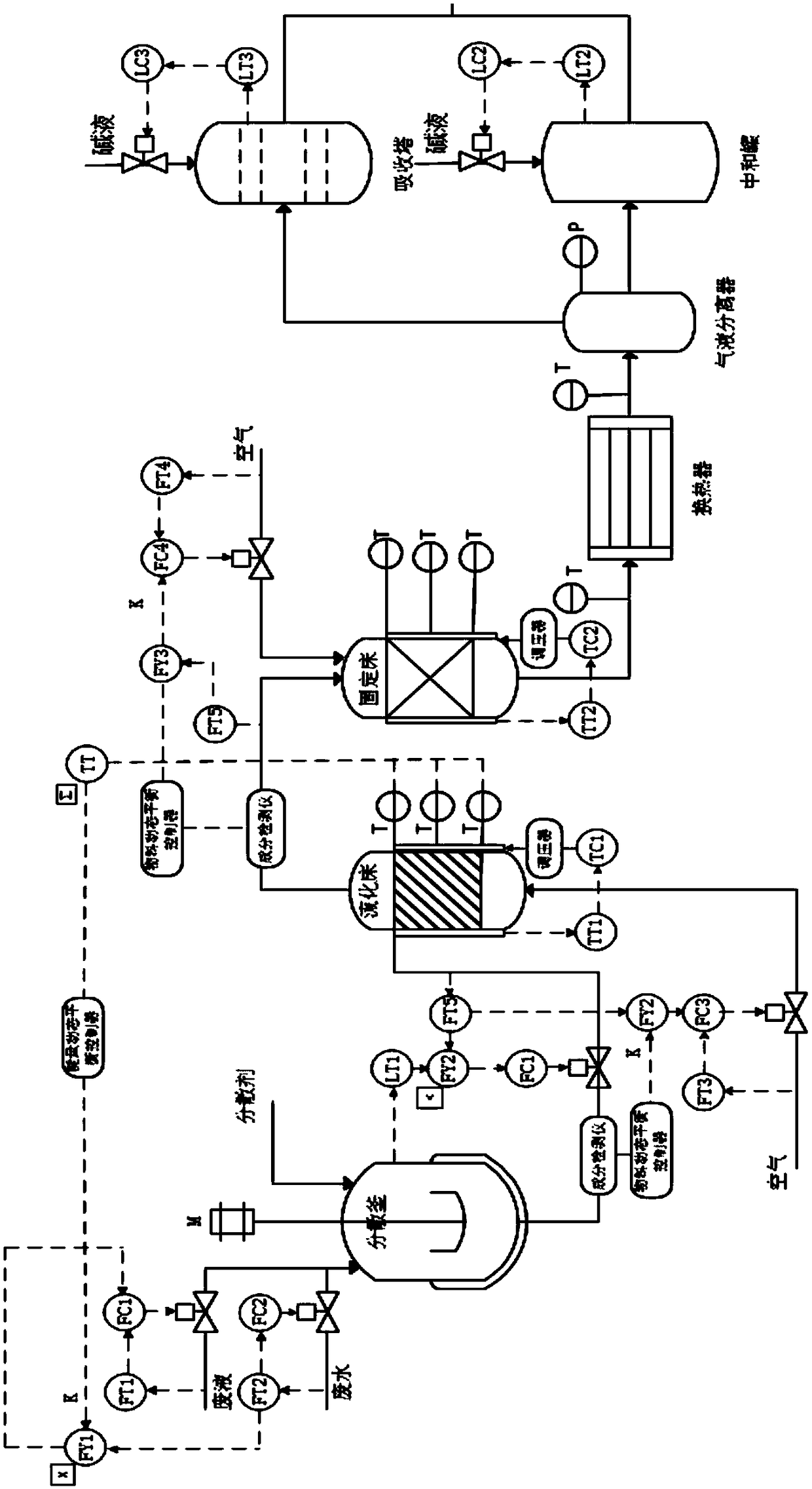

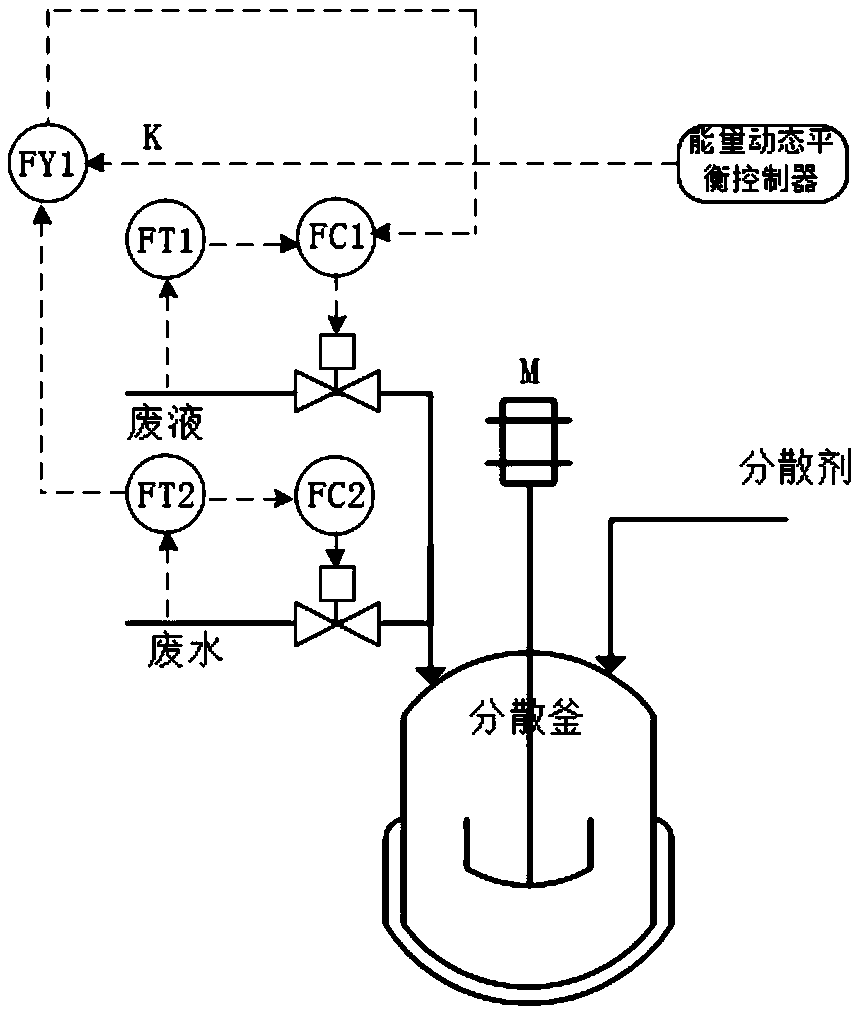

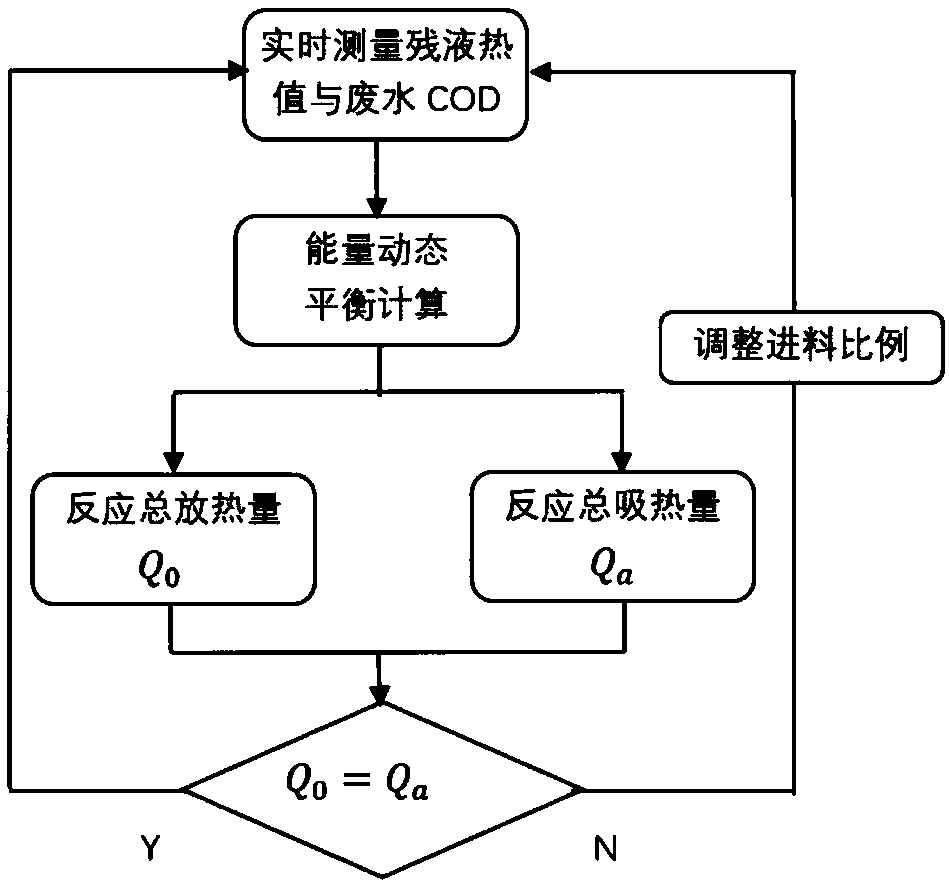

[0040] Such as Figure 1-5 , according to the process flow of the combined purification system, an automatic control system for the combined purification of o- / p-chlorobenzaldehyde rectification residue and process wastewater has the following parts, which are respectively the dispersion tank unit, the fluidized bed unit, and the fixed bed unit , Gas-liquid separator unit, neutralization absorption unit.

[0041] An automatic control system for the joint purification of o- / p-chlorobenzaldehyde rectification residue and process wastewater, including: the automatic control system consists of three parts: a man-machine interface, a control cabinet and an actuator. The man-machine interface computer is connected with the control cabinet to control The cabinet uses a logic controller to control the on-site temperature, flow, liquid level and other control units, and the actuator is connected to the control cabinet, including pumps, regulating valves, fans and heaters.

[0042] Acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com