Method and system of preparing ceramsite from municipal sludge

A technology for urban sludge and ceramsite, which is applied in applications, household appliances, clay products, etc., can solve the problems of increasing the amount of sludge added, and achieve the effects of reducing energy consumption, high temperature, and reducing environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

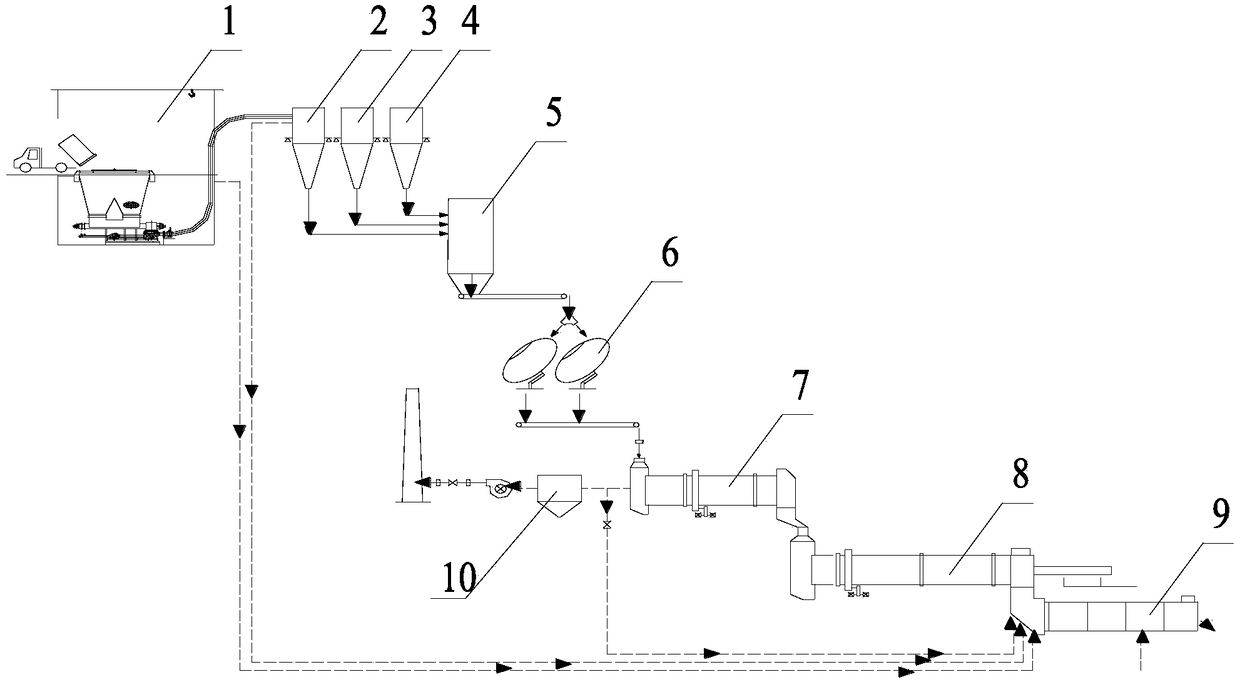

[0031] Such as figure 1 As shown, the preparation system of sludge ceramsite of the present invention includes a granulator 5, and the sludge storage bin 2, the clay bin 3 and the fly ash bin 4 are all connected with the granulator 5, and the outlet of the granulator 5 is connected into a ball machine 6, the exhaust gas outlet of the ball forming machine 6 is connected to the flue gas treatment system 10, the material outlet is connected to the dryer 7, the outlet of the dryer 7 is connected to the roaster 8, the outlet of the roaster 8 is connected to the cooling machine 9, and the sludge storage bin 2 A sludge receiving system 1 is provided before, and the sludge receiving system 1 is connected to the sludge storage bin 2 through a sludge pump. Both the sludge receiving system 1 and the sludge storage bin 2 are connected to the roaster 8 throu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com