Novel anticorrosive flame-retardant high-damping rubber material and preparation method thereof

A new material and high damping technology, applied in the field of new materials, can solve the problems of poor storage stability, toxic gas generation, long drying time, etc., and achieve the effect of improving compatibility, simplicity and high preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

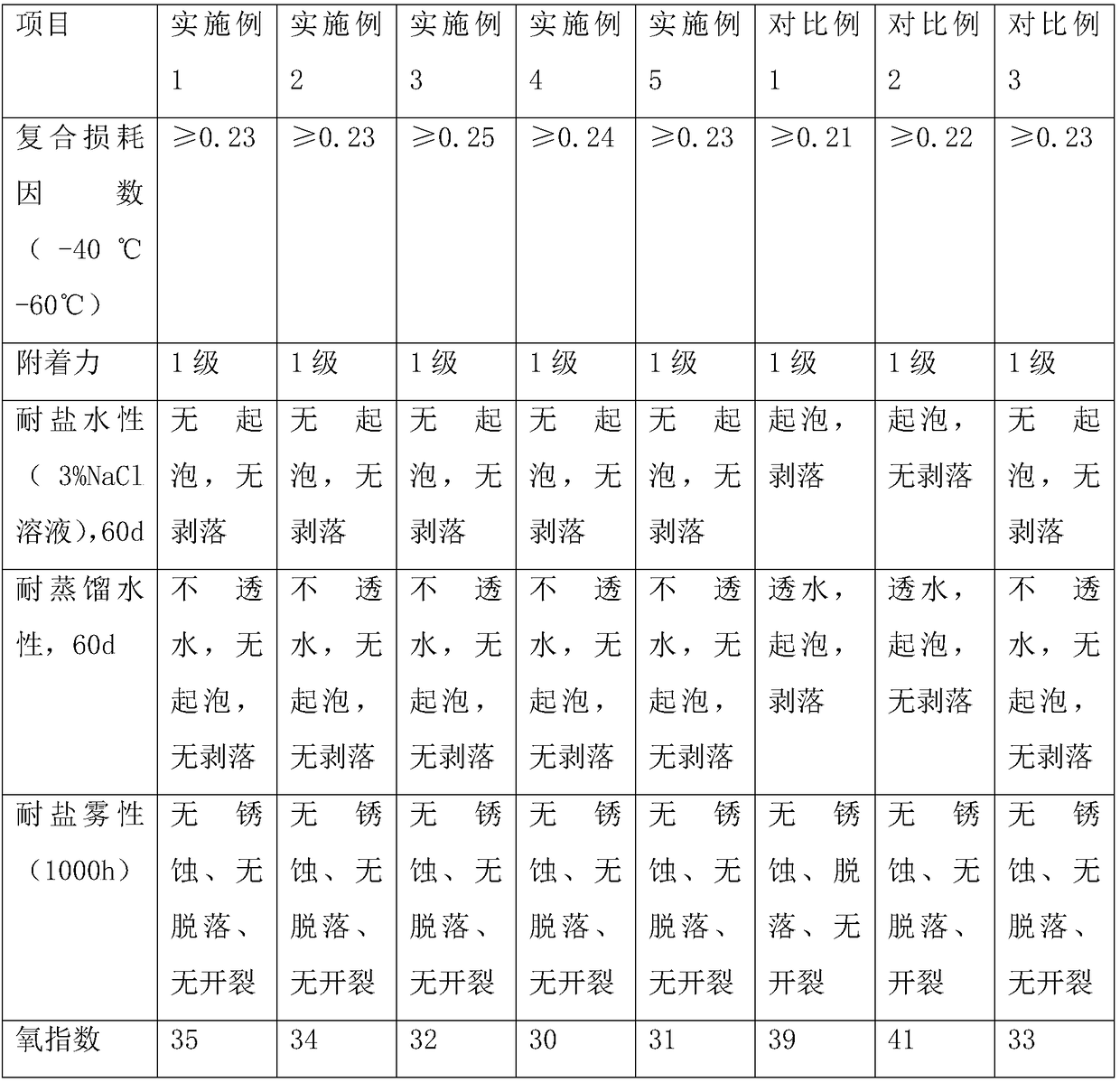

Examples

Embodiment 1

[0031] A new anti-corrosion flame-retardant high-damping rubber material, including the following raw materials in parts by weight: high-phenyl silicone rubber: 80 parts, polyether 2000: 15 parts, low-functionality polyisocyanate: 20 parts, acrylic polymer: 3 parts , Isocyanate prepolymer: 12 parts, damping filler: 25 parts, organic preservative: 1 part, coupling agent: 2 parts, silicon nitrogen flame retardant: 4 parts, other additives: 5 parts.

[0032] The acrylic polymer is methyl methacrylate homopolymer.

[0033] Isocyanate prepolymer is an isocyanate prepolymer synthesized by polyisocyanate and polymer polyol, among which polyisocyanate is polymethylene polyphenyl polyisocyanate, toluene diisocyanate, diphenylmethane diisocyanate, trimethylhexamethylene One or more of base diisocyanate and tetramethylxylylene diisocyanate; the polymer polyol is one or more of polyether polyol and polyester diol.

[0034] The damping filler is barium sulfate or acicular wollastonite.

...

Embodiment 2

[0041] A new anti-corrosion, flame-retardant and high-damping rubber material, including the following raw materials in parts by weight: high-phenyl silicone rubber: 85 parts, polyether 2000: 20 parts, low-functionality polyisocyanate: 25 parts, acrylic polymer: 4 parts , Isocyanate prepolymer: 13 parts, damping filler: 30 parts, organic preservative: 2 parts, coupling agent: 3 parts, silicon nitrogen flame retardant: 5 parts, other additives: 7 parts.

[0042] The acrylic polymer is methyl methacrylate homopolymer.

[0043]Isocyanate prepolymer is an isocyanate prepolymer synthesized by polyisocyanate and polymer polyol, among which polyisocyanate is polymethylene polyphenyl polyisocyanate, toluene diisocyanate, diphenylmethane diisocyanate, trimethylhexamethylene One or more of base diisocyanate and tetramethylxylylene diisocyanate; the polymer polyol is one or more of polyether polyol and polyester diol.

[0044] The damping filler is barium sulfate or acicular wollastonit...

Embodiment 3

[0051] A new anti-corrosion, flame-retardant and high-damping rubber material, including the following raw materials in parts by weight: high-phenyl silicone rubber: 90 parts, polyether 2000: 25 parts, low-functionality polyisocyanate: 30 parts, acrylic polymer: 5 parts , Isocyanate prepolymer: 14 parts, damping filler: 35 parts, organic preservative: 3 parts, coupling agent: 4 parts, silicon nitrogen flame retardant: 6 parts, other additives: 9 parts.

[0052] The acrylic polymer is methyl methacrylate homopolymer.

[0053] Isocyanate prepolymer is an isocyanate prepolymer synthesized by polyisocyanate and polymer polyol, among which polyisocyanate is polymethylene polyphenyl polyisocyanate, toluene diisocyanate, diphenylmethane diisocyanate, trimethylhexamethylene One or more of base diisocyanate and tetramethylxylylene diisocyanate; the polymer polyol is one or more of polyether polyol and polyester diol.

[0054] The damping filler is barium sulfate or acicular wollastoni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com