Acrylic adhesive with heat insulation performance for colored stone metal tile and preparation method thereof

A technology of acrylic glue and metal tiles, applied in the direction of adhesive additives, adhesive types, ester copolymer adhesives, etc., can solve the problems of poor water resistance, easy yellowing, weak adhesion, etc., and achieve anti-sagging Good performance, excellent flexibility, good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

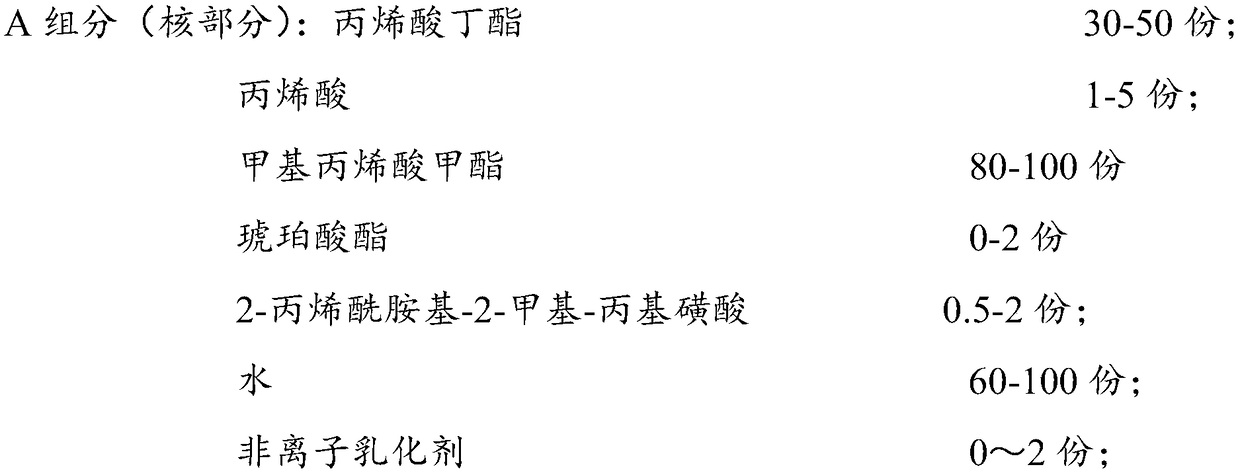

[0074] An acrylic emulsion adhesive for colored stone metal tiles, including a bottom adhesive and a surface adhesive, the raw material formula components of the bottom adhesive are as follows:

[0075]

[0076]

[0077] C component (initiator solution): 2.5 parts of ammonium persulfate;

[0078] 100 parts of deionized water;

[0079] D component (emulsifier solution): 1.5 parts of succinate;

[0080] 3 parts of 2-acrylamido-2-methyl-propylsulfonic acid;

[0081] 300 parts of deionized water;

[0082]

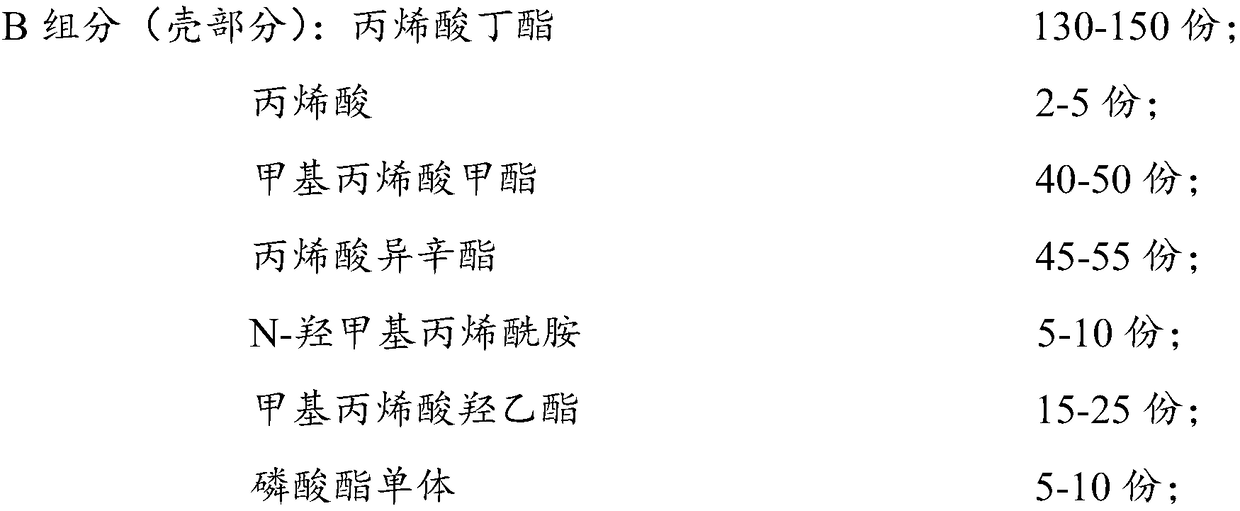

[0083] The raw material formula component of described surface adhesive is as follows:

[0084]

[0085]

[0086] H component (initiator solution): 2.5 parts of ammonium persulfate;

[0087] 100 parts of deionized water;

[0088] Component I (emulsifier solution): 4.5 parts of 2-acrylamido-2-methyl-propylsulfonic acid;

[0089] 300 parts of deionized water;

[0090]

[0091] K component ITO / SiO 2 50 parts of slurry.

[0092] The preparation method of ...

Embodiment 2

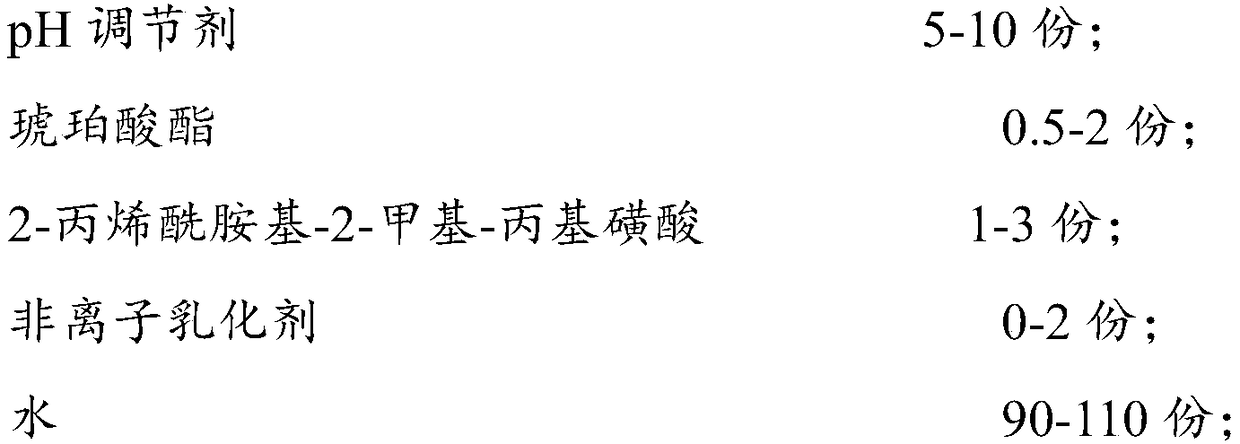

[0115] An acrylic emulsion adhesive for colored stone metal tiles, including a bottom adhesive and a surface adhesive, the raw material formula components of the bottom adhesive are as follows:

[0116]

[0117]

[0118]

[0119] C component (initiator solution): 2.5 parts of ammonium persulfate;

[0120] 100 parts of deionized water;

[0121] D component (emulsifier solution): 3 parts of polyoxyethylene laurate;

[0122] 1.5 parts of 2-acrylamido-2-methyl-propylsulfonic acid;

[0123] 300 parts of deionized water;

[0124]

[0125] The raw material formula component of described surface adhesive is as follows:

[0126]

[0127]

[0128]

[0129] H component (initiator solution): 2.5 parts of ammonium persulfate;

[0130] 100 parts of deionized water;

[0131] Component I (emulsifier solution): 4.5 parts of 2-acrylamido-2-methyl-propylsulfonic acid;

[0132] 300 parts of deionized water;

[0133]

[0134] K component ITO / SiO 2 45 parts of slurry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com