Oil-gas equipment safety protection composition and preparation method thereof

A safety protection and composition technology, which is applied in the field of oil and gas equipment safety protection composition and its preparation, can solve the problems of reducing the volatilization speed of liquid, easy sedimentation, slow spreading speed, etc., so as to improve the ability to form a water film, improve the anti-oxidation ability, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

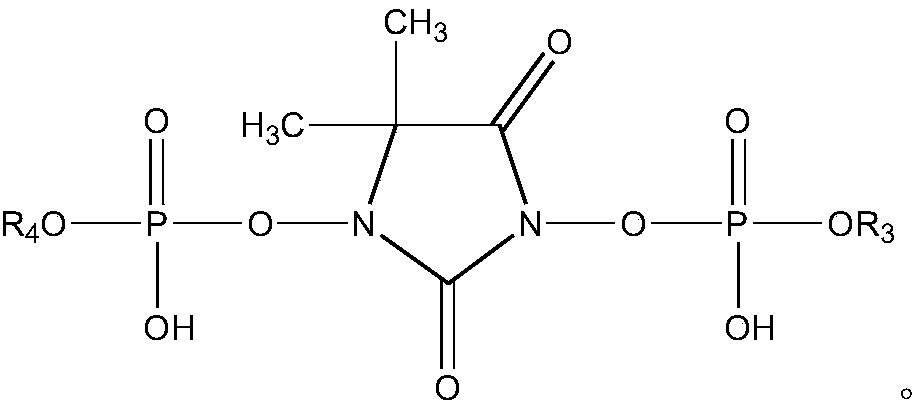

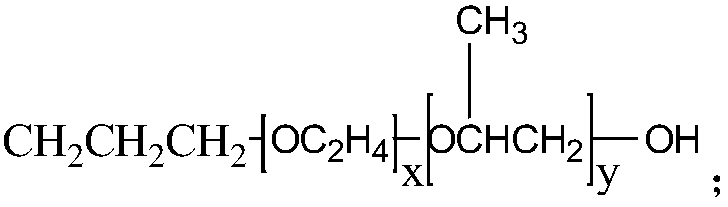

[0090] Embodiment 1 of the present invention provides an oil and gas equipment safety protection composition, which comprises 1 part of betaine derivative, 1 part of ammonium oxide, 0.3 part of fatty alcohol polyoxyethylene in parts by weight Ether, 0.6 parts of (A) formula compound, 0.3 parts of (B) formula compound, 0.15 parts of (C) formula compound and 8 parts of water;

[0091] said x is 12; y is 8;

[0092]

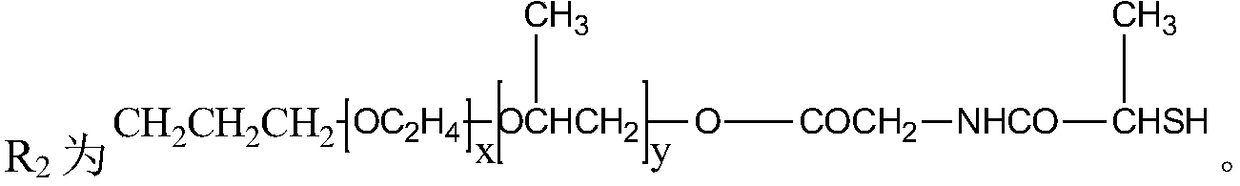

[0093] Wherein the R in the formula (B) compound structure 1 , R 2 respectively

[0094]

[0095] The preparation method of described (B) formula compound is as follows:

[0096] (1) Dissolve 1g of chloroplatinic acid in 100mL of isopropanol solution, prepare chloroplatinic acid-isopropanol catalyst at room temperature, then remove water from it, and place it in a dark place for 24 hours before use. The final color is orange-yellow;

[0097] (2) In a 250mL three-necked flask equipped with a stirrer, a reflux condenser and a thermometer, add hydrogen-c...

Embodiment 2

[0115] Example 2 of the present invention provides an oil and gas equipment safety protection composition, the embodiment of which is the same as that of Example 1, except that, calculated in parts by weight, the oil and gas equipment safety protection composition contains 10 parts of betaine derivatives , 10 parts of ammonium oxide, 3 parts of fatty alcohol polyoxyethylene ether, 3 parts of (A) formula compound, 3 parts of (B) formula compound, 1.0 part of (C) formula compound and 30 parts of water.

Embodiment 3

[0117] Example 3 of the present invention provides an oil and gas equipment safety protection composition, the embodiment of which is the same as that of Example 1, except that, calculated by weight, the oil and gas equipment safety protection composition contains 0.1 parts of betaine derivatives , 0.5 part of ammonium oxide, 0.1 part of fatty alcohol polyoxyethylene ether, 0.1 part of (A) formula compound, 0.1 part of (B) formula compound, 0.01 part of (C) formula compound and 1 part of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com