Ultrafiltration membrane for stevia rebaudiana purification and preparation method thereof

A technology of ultrafiltration membrane and stevia, applied in the preparation of sugar derivatives, chemical instruments and methods, membranes, etc., can solve the problems of cumbersome solvent treatment, large solvent consumption of macroporous adsorption resin columns, and easy pollution of filter membranes , to achieve the effect of avoiding the reduction of permeation flux, good separation effect and shortening filtration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

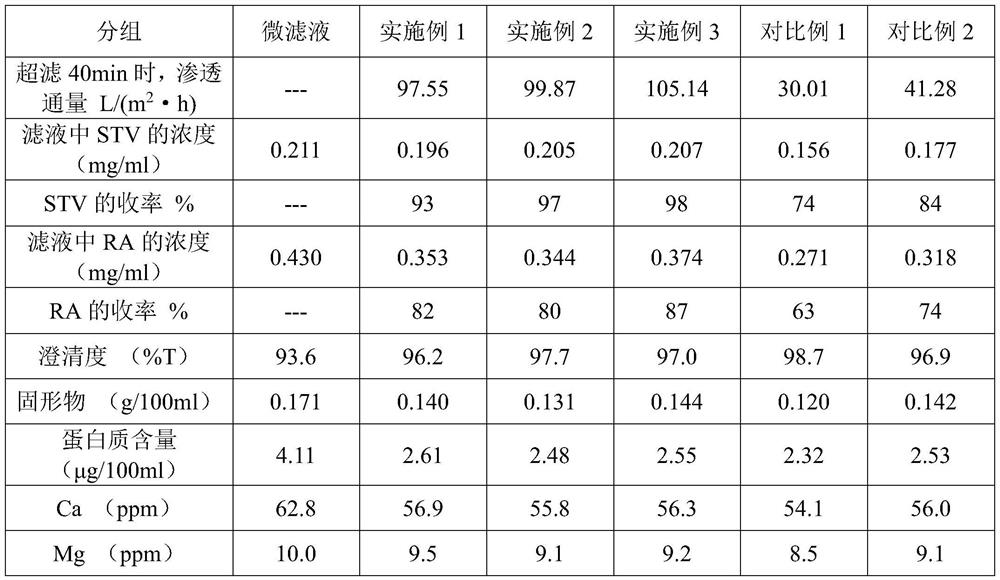

Examples

Embodiment 1

[0025] An ultrafiltration membrane for stevia purification comprises a metal mesh and a calcium-doped silicon dioxide membrane attached to the surface of the metal mesh.

[0026] The preparation method of the ultrafiltration membrane for the above-mentioned stevia purification comprises the steps of: taking 0.07mol of 1,3-bis(trimethylsiloxy)propane, 0.1mol of tetraethyl orthosilicate, and 0.01mol of calcium chloride , adding 73g of ethanol, stirring at high speed until the solution is clear, then adding 73g of hydrochloric acid aqueous solution with a mass fraction of 0.3wt%, and continuously stirring at room temperature at a speed of 500r / min for 13h to obtain a sol;

[0027] Take a stainless steel mesh with a pore size of 1.5 μm, ultrasonically clean it twice with acetone, ethanol, and water, each time for 10 minutes, and then dry it; evenly coat the sol on the surface of the stainless steel mesh, then sinter at 350°C for 2 hours, and repeat the coating- The sintering step ...

Embodiment 2

[0029] An ultrafiltration membrane for stevia purification comprises a metal mesh and a calcium-doped silicon dioxide membrane attached to the surface of the metal mesh.

[0030] The preparation method of the ultrafiltration membrane for the above-mentioned stevia purification comprises the steps of: taking 0.08mol of 1,3-bis(trimethylsiloxy)propane, 0.1mol of tetraethyl orthosilicate, and 0.005mol of calcium chloride , added to 52g of ethanol, stirred at high speed until the solution was clear, then added 62.5g of hydrochloric acid aqueous solution with a mass fraction of 0.4wt%, and continued to stir at room temperature at a speed of 500r / min for 15h to obtain a sol;

[0031] Take a stainless steel mesh with a pore size of 1.5 μm, ultrasonically clean it twice with acetone, ethanol, and water in sequence, each time for 10 minutes, and then dry it; evenly coat the sol on the surface of the stainless steel mesh, then sinter at 300°C for 2.5 hours, and repeat the coating -Sinte...

Embodiment 3

[0033] An ultrafiltration membrane for stevia purification comprises a metal mesh and a calcium-doped silicon dioxide membrane attached to the surface of the metal mesh.

[0034] The preparation method of the ultrafiltration membrane for the above-mentioned stevia purification comprises the steps of: taking 0.075mol of 1,3-bis(trimethylsiloxy)propane, 0.1mol of tetraethyl orthosilicate, and 0.008mol of calcium chloride , added to 62.5g of ethanol, stirred at high speed until the solution was clear, then added 68g of hydrochloric acid aqueous solution with a mass fraction of 0.35wt%, and continued to stir at room temperature at a speed of 500r / min for 14h to obtain a sol;

[0035] Take a stainless steel mesh with a pore size of 1.5 μm, ultrasonically clean it twice with acetone, ethanol, and water, each time for 10 minutes, and then dry it; evenly coat the sol on the surface of the stainless steel mesh, then sinter at 320°C for 2 hours, and repeat the coating- The sintering ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com