Biogas slurry waste heat recycling and utilization system and working method

A technology of waste heat recovery and biogas slurry, which is applied in the field of biogas slurry waste heat recovery and utilization system, can solve the problems of low heat energy recovery rate of biogas slurry, achieve the effect of improving heat exchange response speed, increasing heat exchange contact area, and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

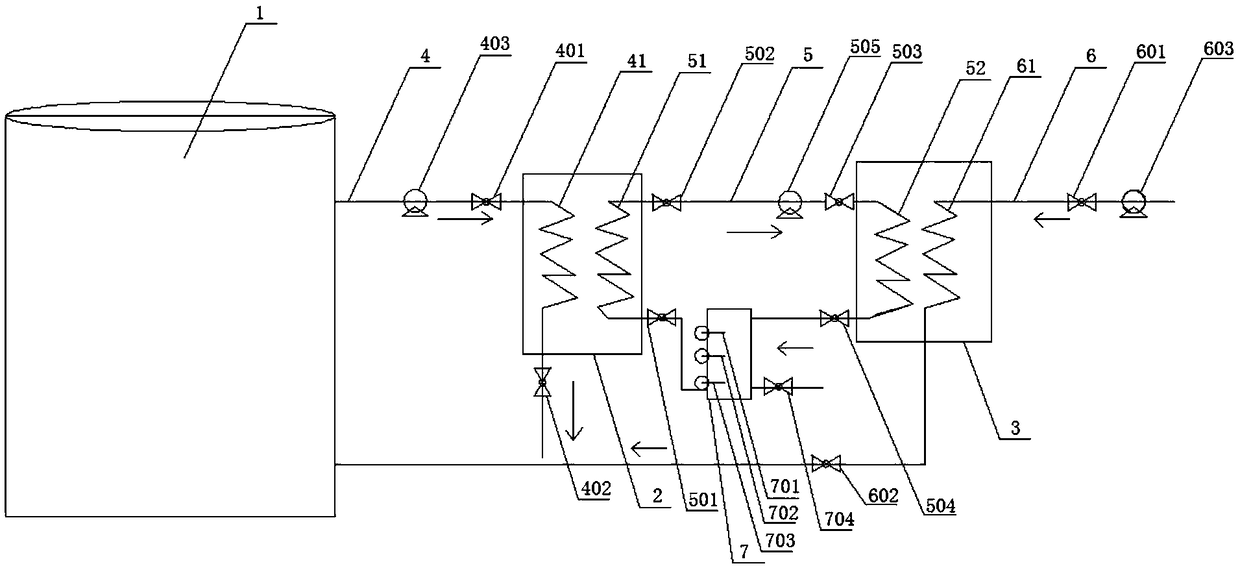

[0035] Biogas slurry waste heat recovery and utilization system, including fermenter reactor 1, evaporator 2, condenser 3, biogas slurry discharge pipeline 4, heat medium circulation pipeline 5 and raw material feed pipeline 6;

[0036] The biogas slurry discharge pipeline 4 communicates with the interior of the fermenter reactor 1, and is provided with a first valve 401, a second valve 402 and a discharge pump 403;

[0037] The raw material feed pipeline 6 communicates with the interior of the fermenter reactor 1, on which a third valve 601, a fourth valve 602 and a feed pump 603 are arranged;

[0038] The heat supply section 41 of the biogas slurry discharge pipeline 4 and the heat absorption section 51 of the heat medium circulation pipeline 5 are fixedly arranged in the evaporator 2 together;

[0039] The heat release section 52 of the heat medium circulation pipeline 5 and the heat exchange section 61 of the raw material feed pipeline 6 are fixedly arranged in the condens...

Embodiment 2

[0045] In this embodiment, on the basis of Embodiment 1, an upper liquid level sensor 701 and a lower liquid level sensor 702 are provided in the heat medium buffer tank 7, and the upper liquid level sensor 701 communicates with the controller to control the heat-absorbing water outlet valve 502. Opening of the heat release water inlet valve 503 and the fan 505; the lower liquid level sensor 702 is connected with the controller to control the closing of the heat absorption water inlet valve 501 and the heat release water outlet valve 504.

[0046] The liquid level sensors used in this embodiment are all float type liquid level sensors, and the controller model is Siemens S7-200SMART controller.

[0047]The biogas slurry waste heat recovery and utilization system provided in this embodiment is connected to the controller through the upper liquid level sensor and the lower liquid level sensor set in the heat medium buffer tank, and controls the automatic operation of the correspo...

Embodiment 3

[0049] In this embodiment, on the basis of Embodiment 2, a fluid replenishment sensor 703 and a fluid injection valve 704 are further provided on the heat medium buffer tank 7 . The liquid replenishment sensor used in this embodiment is a float type liquid level sensor.

[0050] The biogas slurry waste heat recovery and utilization system provided in this embodiment monitors the liquid heat medium storage in the heat medium buffer tank through the liquid replenishment sensor installed in the heat medium buffer tank, and maintains continuous recovery and utilization of biogas slurry waste heat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com