High-entropy alloy reinforced 2024 aluminum based composite material and preparation method thereof

A technology of aluminum matrix composite materials and high entropy alloys, which is applied in the field of aluminum matrix composite materials and can solve problems such as poor wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention also discloses a method for preparing a high-entropy alloy reinforced 2024 aluminum-based composite material, which can successfully prepare Al x CoCrFeNi high-entropy alloy reinforced 2024 aluminum matrix composite material, using 2024 aluminum alloy powder and high-entropy alloy powder as raw materials, the implementation steps are: according to the design volume fraction, take Al x CoCrFeNi particles and 2024 aluminum alloy powder; mixed powder by ball milling; the resulting mixed powder is put into a mold for pre-pressing; after pre-pressing, it is placed in a spark plasma sintering equipment for sintering, and after cooling with the furnace, a high-entropy alloy reinforced 2024 aluminum matrix composite material is obtained. The invention has simple preparation process, short production period, controllable size and content of second-phase reinforced particles, and can produce composite material with high density and excellent performance with relative...

Embodiment 1

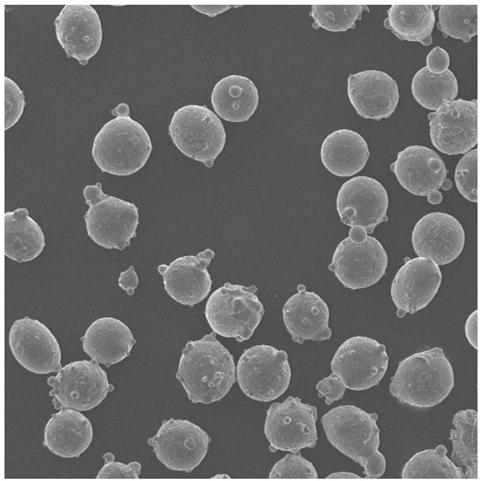

[0039] Such as figure 1 As shown, the selected crystal structure is Al with an FCC particle size of 80 μm 0.2 CoCrFeNi high-entropy alloy powder is mixed with 2024 aluminum alloy powder in a ball mill according to the volume fraction of 5vol%, and the grinding ball is agate ball, the rotating speed is 180r / min, the ball-to-material ratio is 5:1, and the ball-milling time is 6h. figure 2 Mixed powders shown. Put the mixed powder into a graphite mold for SPS sintering. The sintering pressure is 30MPa, the heating rate is 100°C / min, the sintering temperature is 500°C, and the heat preservation is 5 minutes. After the heat preservation time is over, the sintering is stopped. When the temperature cools to room temperature, the pressure is released. Take out the mold for demoulding to get dense 5vol% Al 0.2 FeCrCoNi / 2024 aluminum matrix composite block.

Embodiment 2

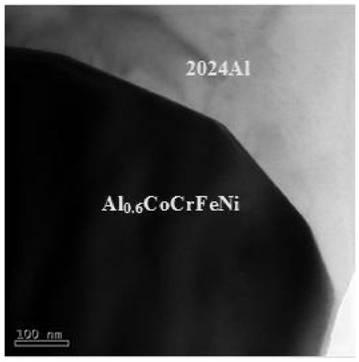

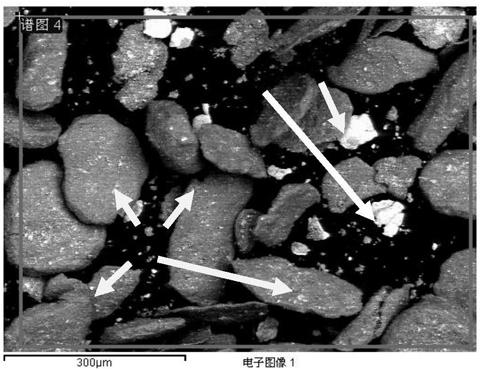

[0041] Select Al with a crystal structure of FCC+BCC and a particle size of 80 μm 0.6 CoCrFeNi high-entropy alloy powder is mixed with 2024 aluminum alloy powder in a ball mill according to the volume fraction of 10vol%, using a stainless steel ball mill pot, the ball is agate ball, the speed is 250r / min, the ball-to-material ratio is 5:1, and the ball milling time is 6h. Put the mixed powder into a graphite mold for SPS sintering. The initial sintering pressure is 20MPa, the heating rate is 100°C / min to 500°C, and then the heating rate is 20°C / min to 540°C, and the temperature is kept for 5 minutes. After the holding time is over, the sintering is stopped. When the temperature is cooled to room temperature, the pressure is released, the mold is taken out for demoulding, and a dense 10vol% Al is obtained 0.6 FeCrCoNi / 2024 aluminum matrix composite block. Such as image 3 As shown, the SEM image of the high-entropy alloy reinforced 2024 aluminum matrix composite block prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com