Ultra-fast pulse laser-cold spraying surface processing method for thin-wall structure

An ultra-fast pulse, thin-walled structure technology, applied in metal material coating process, coating, heating inorganic powder coating and other directions, can solve problems such as performance degradation and structural deformation, reduce fine powder particles and reduce gas pressure. , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

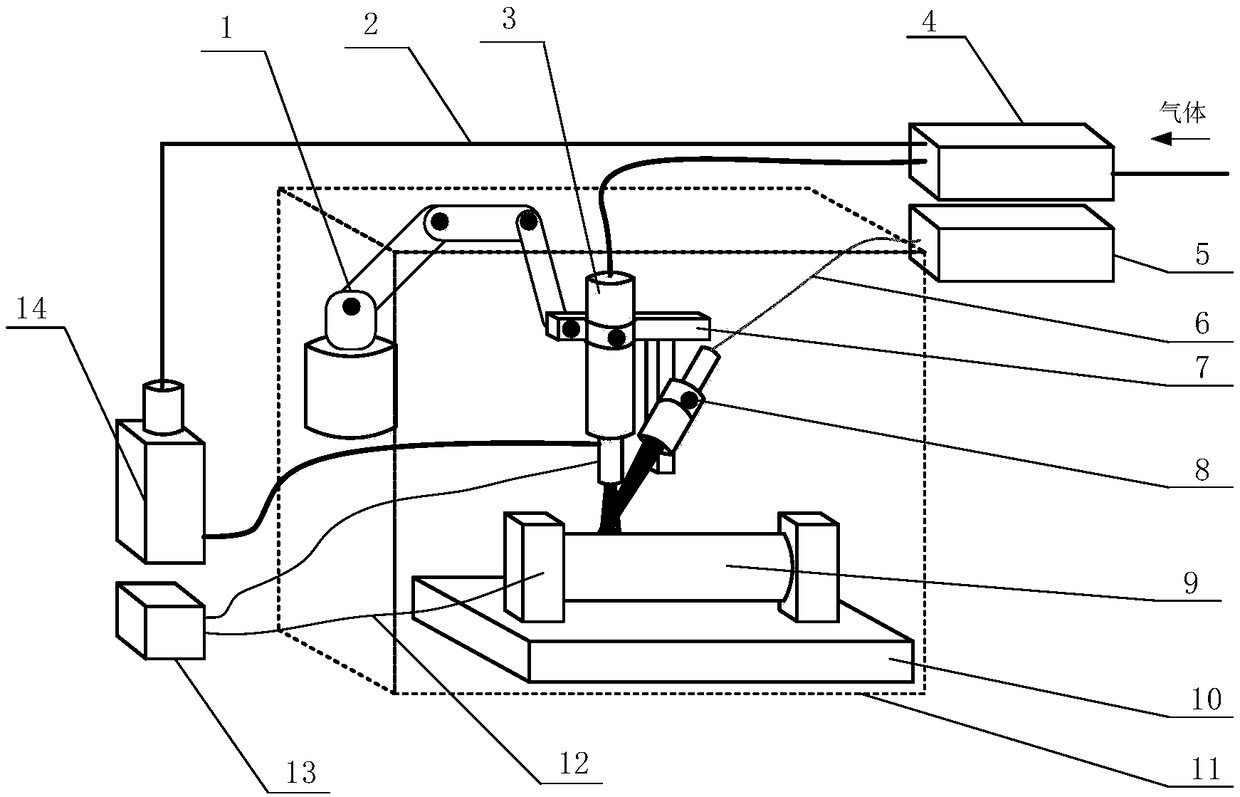

[0036] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

[0037] The thin-wall structure ultrafast pulse laser-cold spraying surface processing method provided by the invention comprises the following steps:

[0038] Construct defect process parameter database;

[0039] Construct the surface three-dimensional model of thin-walled structural defects;

[0040] Identify defect features and calculate defect repair parameters;

[0041] Calculate the trajectory of each moving part;

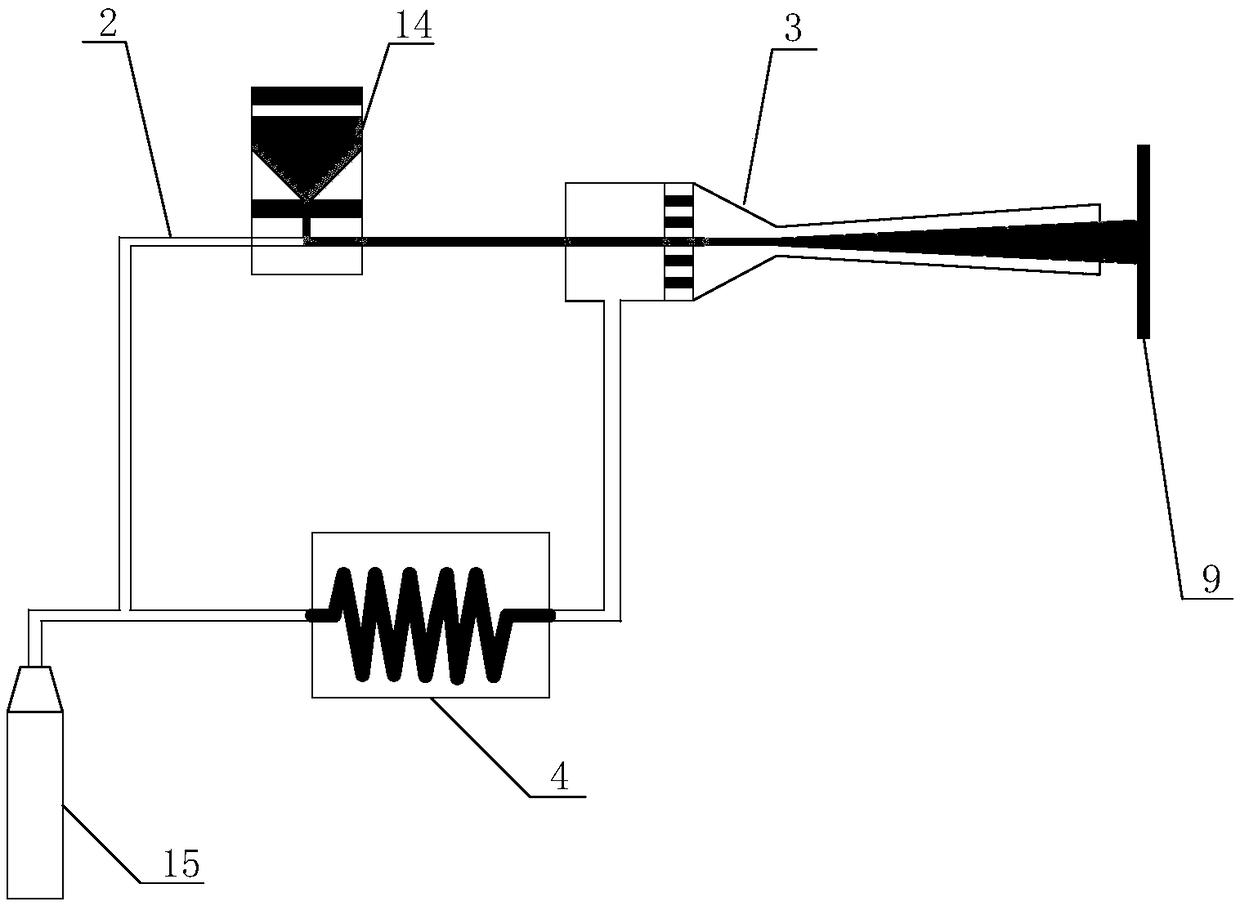

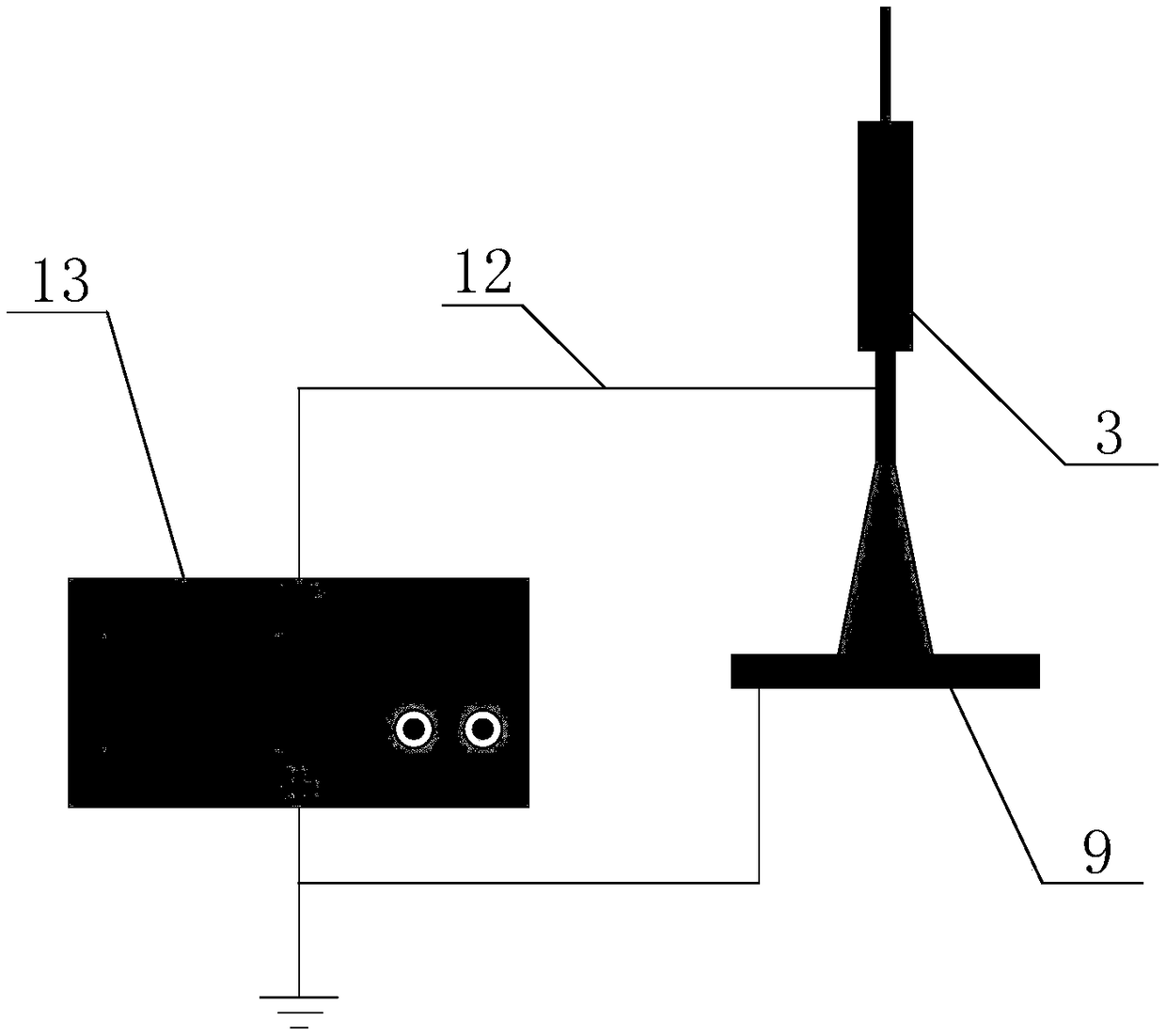

[0042] Provide a laser-cold spraying system, including a cold spraying system, a control module, a laser system, a motion system and a powder charging device, the laser system is used to emit ultrashort pulse laser, so that the matrix material and powder particles can quickly reach a thermoplastic state; The nozzles of the above-mentioned cold spray system and ultrashort pulse laser system are loaded on the motion system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com