A stannite structure cumno 2 Morphology Control Methods of Crystalline Materials

A technology of crystal material and morphology, which is applied in the field of morphology control of spessartite structure CuMnO2 crystal material, can solve the problems of large material size, not fully reflected, unfavorable electrolyte transmission, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

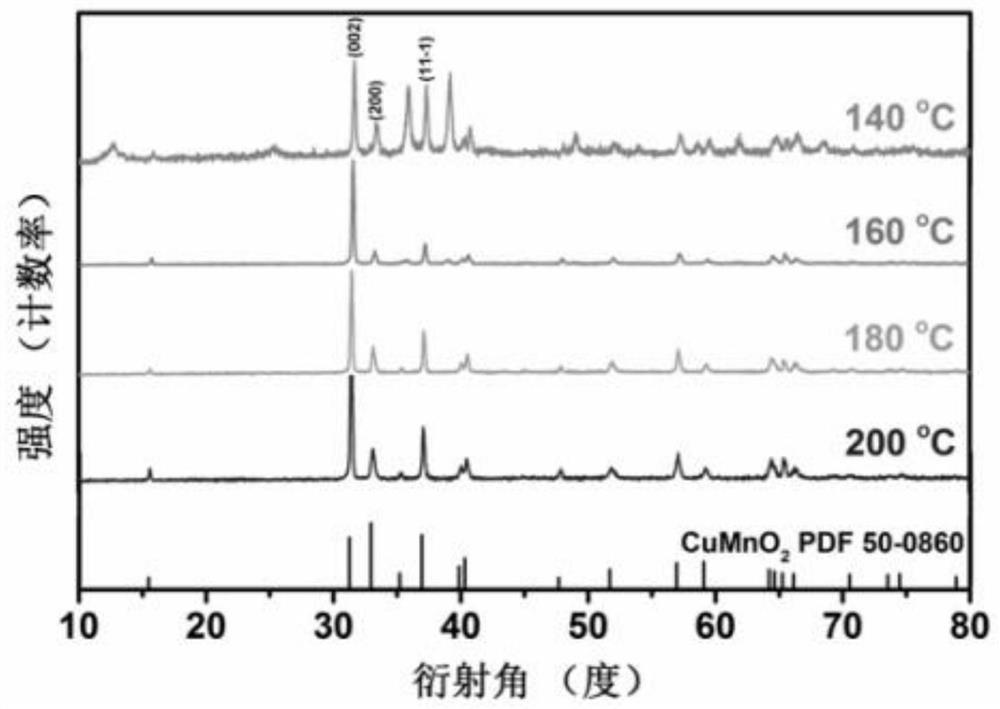

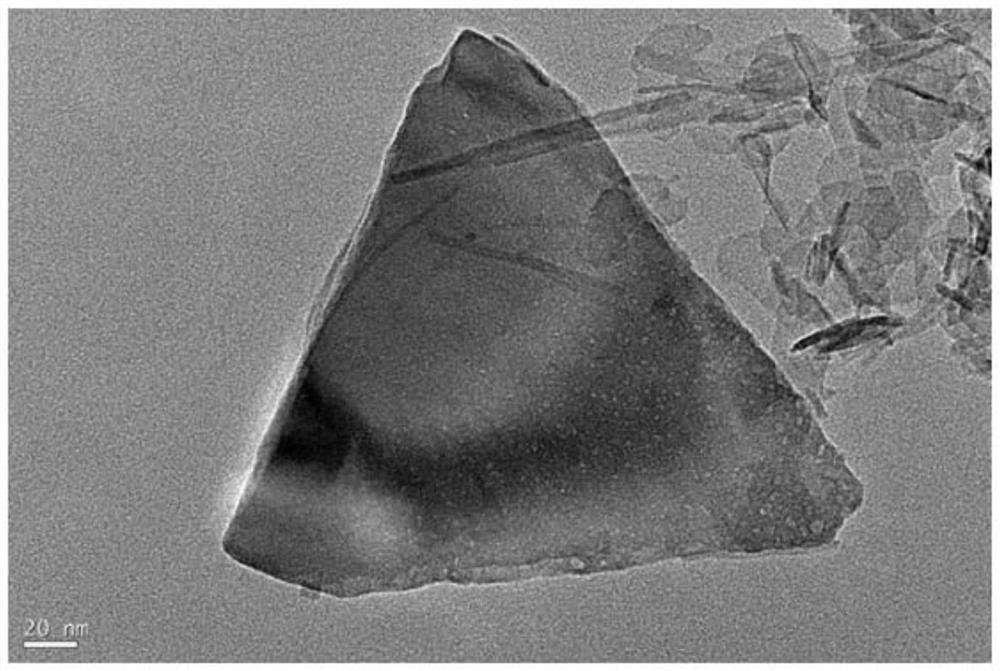

[0033] Example 1 Preparation of Triangular Flake CuMnO 2 crystal material

[0034] Dissolve 0.15g of cetyltrimethylammonium bromide in a mixed solution of 25ML water and 25ML ethanol, then add 5ML NaOH solution (concentration 2mol / L), and then add 2.5ML Mn(CH 3 COO) 2 4H 2 O solution (concentration 0.1mol / L) and 2.5ML Cu(NO 3 ) 2 ·3H 2 O solution (concentration 0.1 mol / L). Stir well for 2 hours until the mixture is uniform, transfer to a 100ML reactor, and react at 130-150°C for 24 hours. After the reaction, let it cool down naturally, take out the samples and wash them with water and ethanol respectively, repeat this step three times, and dry them in an oven at 70°C for 6 hours to obtain triangular flake CuMnO 2 Crystal material, denoted as 1#.

Embodiment 2

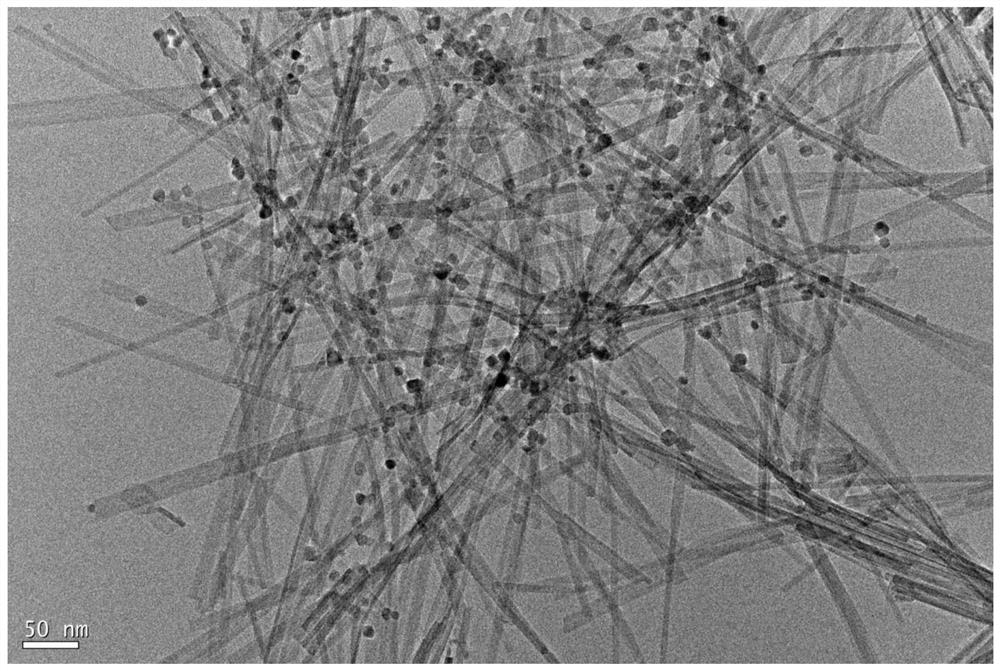

[0035] Example 2 Preparation of nanowire CuMnO 2 crystal material

[0036] Dissolve 0.15g of cetyltrimethylammonium bromide in a mixed solution of 25ML water and 25ML ethanol, then add 5ML NaOH solution (concentration 2mol / L), and then add 2.5ML Mn(CH 3 COO) 2 4H 2 O solution (concentration 0.1mol / L) and 2.5ML Cu(NO 3 ) 2 ·3H 2 O solution (concentration 0.1 mol / L). Stir well for 2 hours until the mixture is uniform, transfer to a 100ML reactor, and react at 150-170°C for 24 hours. After the reaction, wait for it to cool naturally, take out the sample and wash it with water and ethanol respectively, repeat this step three times, and dry it in a 70°C oven for 6 hours to obtain nanowire-like CuMnO 2 The crystal material is recorded as 2#.

Embodiment 3

[0037] Example 3 Preparation of hexagonal prism CuMnO 2 crystal material

[0038]Dissolve 0.15g of cetyltrimethylammonium bromide in a mixed solution of 25ML water and 25ML ethanol, then add 5ML NaOH solution (concentration 2mol / L), and then add 2.5ML Mn(CH 3 COO) 2 4H 2 O solution (concentration 0.1mol / L) and 2.5ML Cu(NO 3 ) 2 ·3H 2 O solution (concentration 0.1 mol / L). Stir well for 2 hours until the mixture is uniform, transfer to a 100ML reactor, and react at 170-190°C for 24 hours. After the reaction, let it cool down naturally, take out the sample and wash it with water and ethanol respectively, repeat this step three times, and dry it in an oven at 70°C for 6 hours to obtain hexagonal CuMnO 2 The crystal material is recorded as 3#.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com