Multifunctional self-curled polycaprolactam-polyurethane eccentric skin core compound filament and preparation method thereof

A polycaprolactam and composite filament technology is applied in the field of spinning, which can solve the problems of high spinning failure rate, large difference in flow properties, and easy channeling of composites, and achieves the effects of super soft stretchability and improved elasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] A method for preparing multifunctional self-crimping polycaprolactam-polyurethane eccentric sheath-core composite filaments, comprising the following steps: 1) Drying: drying polycaprolactam slices and polyurethane slices respectively, the drying temperature of polyurethane slices is 65-70°C, The drying time is 45-50min; the drying temperature of polycaprolactam is 115-125°C, and the drying time is 45-50min.

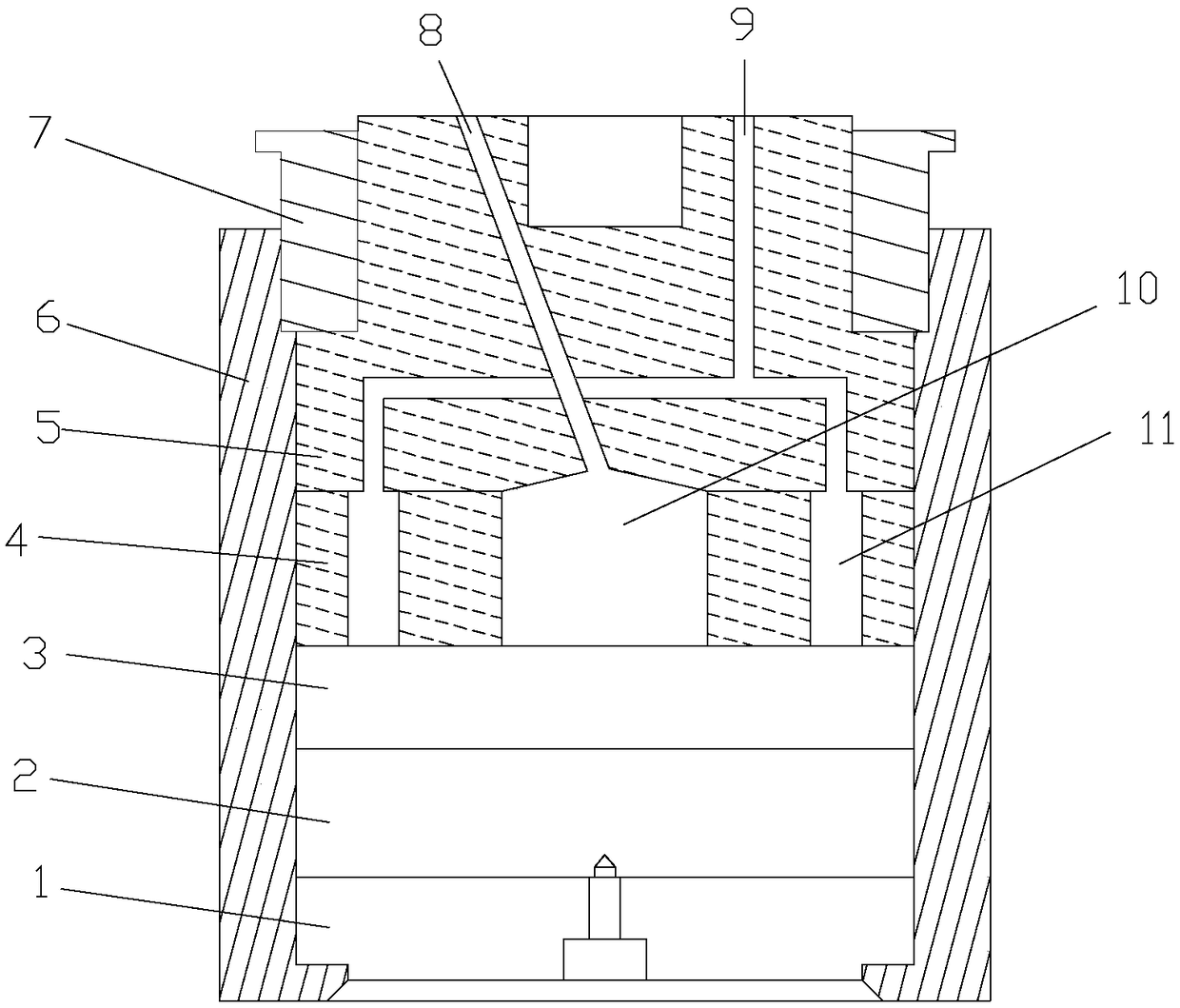

[0045] 2) UDY spinning: Polyurethane slices are melted and extruded by the screw, enter the auxiliary box, and then enter the main box after the distribution and metering of the polyurethane melt. In the main box, the polyurethane melt enters the eccentric skin-core composite component; The composite functional masterbatch is mixed in the caprolactam chips, melted and extruded by the screw, and enters the main box for distribution and metering of the polycaprolactam melt, and then enters the eccentric skin-core composite component, between the distribution plate an...

Embodiment l

[0052] A multifunctional self-crimping polycaprolactam-polyurethane eccentric sheath-core composite filament, the cortex is polycaprolactam containing composite functional masterbatch, and the core layer is polyurethane. The mass ratio of the skin layer to the core layer is 50:50.

[0053] Among them, the relative viscosity of the polycaprolactam is 3.3±0.020, the melting point is 221° C., and the water content of the dry slice is less than 140 ppm. The relative viscosity of the polyurethane is 1.37±0.020, the melting point is 180°C, and the water content of the dry chips is less than 60ppm. The composite functional masterbatch contains anti-ultraviolet component, antistatic component and antibacterial component, wherein the total component content is 25%, the water content of the masterbatch is less than 100ppm, and the addition amount of the composite functional masterbatch in the cortex is 2wt%.

[0054] A preparation method of multifunctional self-crimping polycaprolactam...

Embodiment 2

[0060] The difference between this embodiment and embodiment 1 is that the temperature of the spinning box is 265°C. The draw ratio is 2.5, the stretching temperature is 60°C, and the heat setting temperature is 80°C.

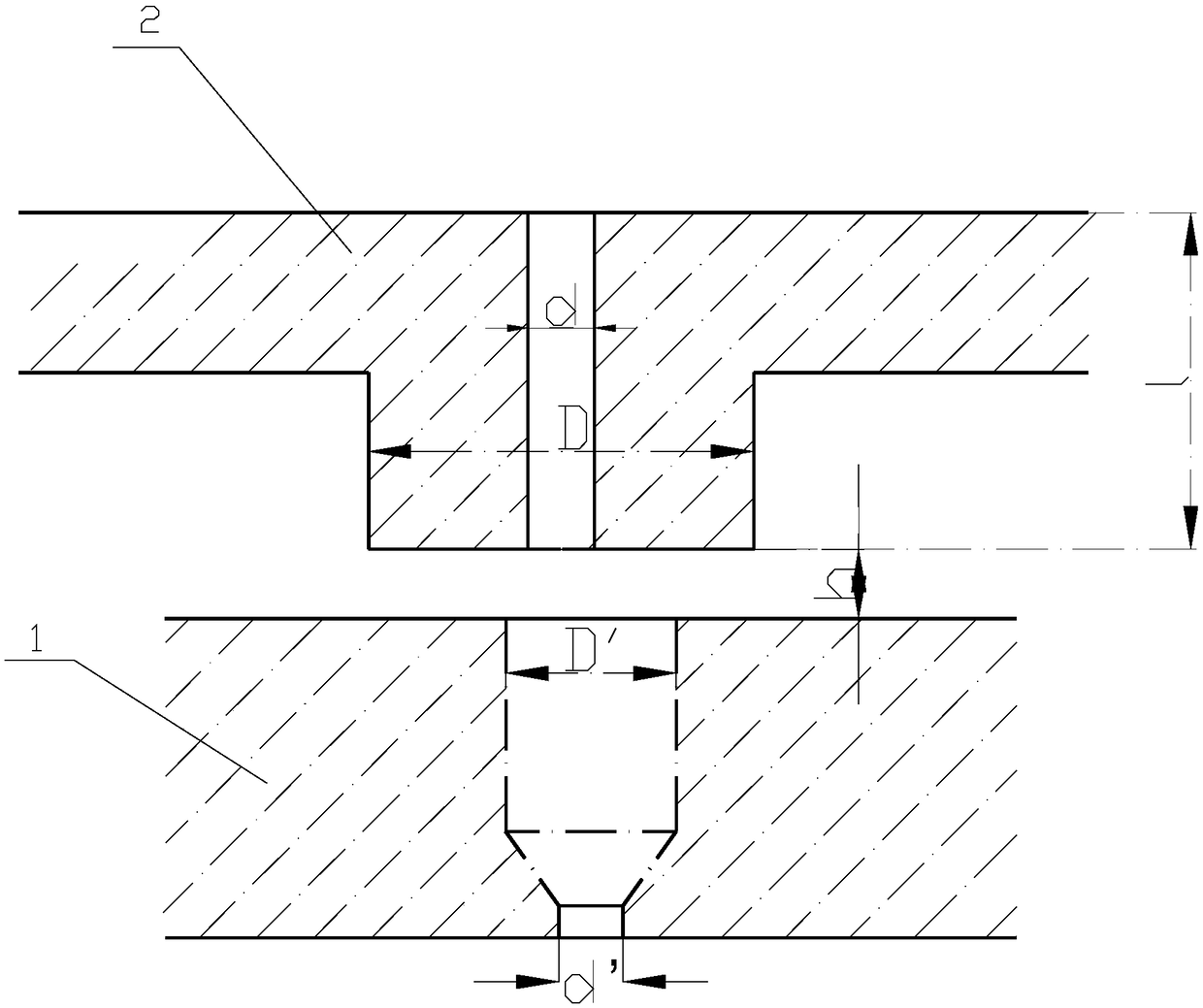

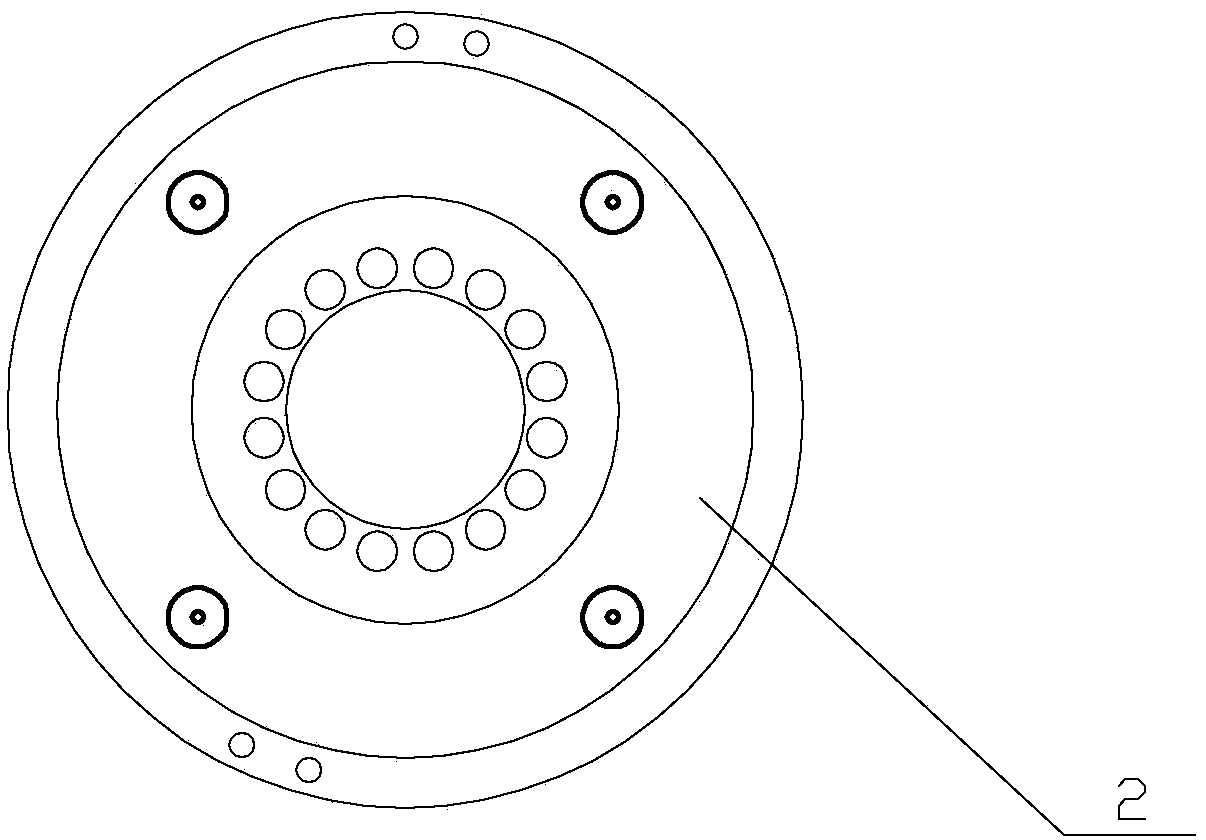

[0061] The specifications of the eccentric skin-core composite component used: the specification of the spinneret is 4 holes, the diameter of the spinneret hole d'=0.3mm; the diameter of the spinneret guide hole D'=3mm; the specification of the distribution plate: the height of the slit h= 0.28mm, eccentric angle θ=1.2°, diameter of circular boss D=6mm, diameter of core layer component pipeline d=lmm, depth of core layer component pipeline l=4mm.

[0062] The specification of the self-crimping composite filament prepared by the above process is 200dtex / 4f.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com