Graphene composite cold plate and fabrication method thereof

A technology of graphene composite and graphene film, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems of poor longitudinal heat transfer and insufficient thermal conductivity of graphite composite cold plates, and improve the overall heat dissipation ability, low density and high heat dissipation performance, and the effect of improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

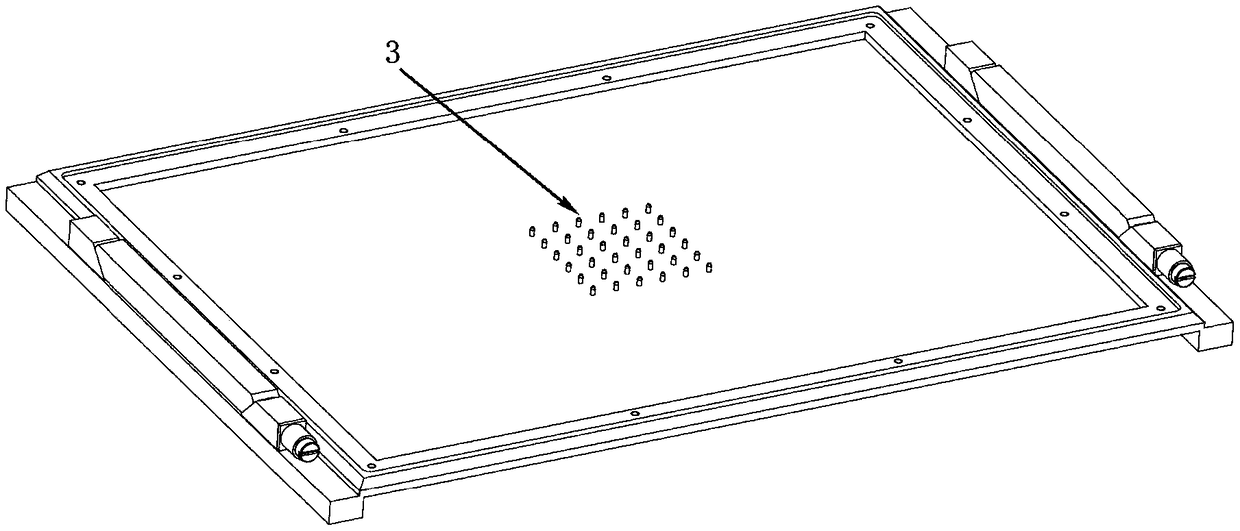

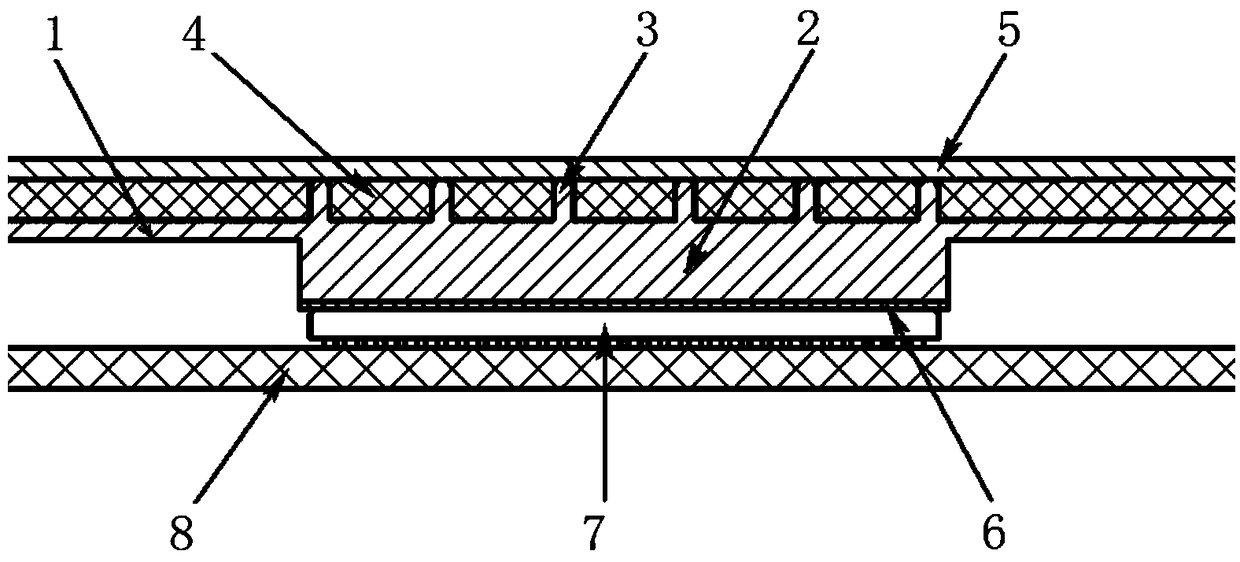

[0035] A graphene composite cold plate of the present invention includes a composite cold plate body 1, a heat dissipation cavity 2, a needle-shaped array heat conduction column 3, a graphene composite film 4, a cover plate 5 and a heat conduction film 6; the composite cold plate body The top of 1 is provided with a concave heat dissipation cavity 2, and the position corresponding to the heat source of the heat dissipation cavity 2 is provided with a vertically arranged needle-shaped array heat conduction column 3; the bottom of the composite cold plate body 1 corresponding to the position of the heat source is convex set up together, through the thermal conduction film 6 and the chip device 7 as the heat source thermally connected; the heat dissipation cavity 2 is provided with a cover plate 5, and the cover plate 5 is fixed around the composite cold plate body 1 to press the graphene composite film 4 fixed in the heat dissipation cavity 2; the needle-shaped array thermal cond...

Embodiment 2

[0039] A kind of graphene composite cold plate of the present invention and preparation method thereof, its steps are as follows:

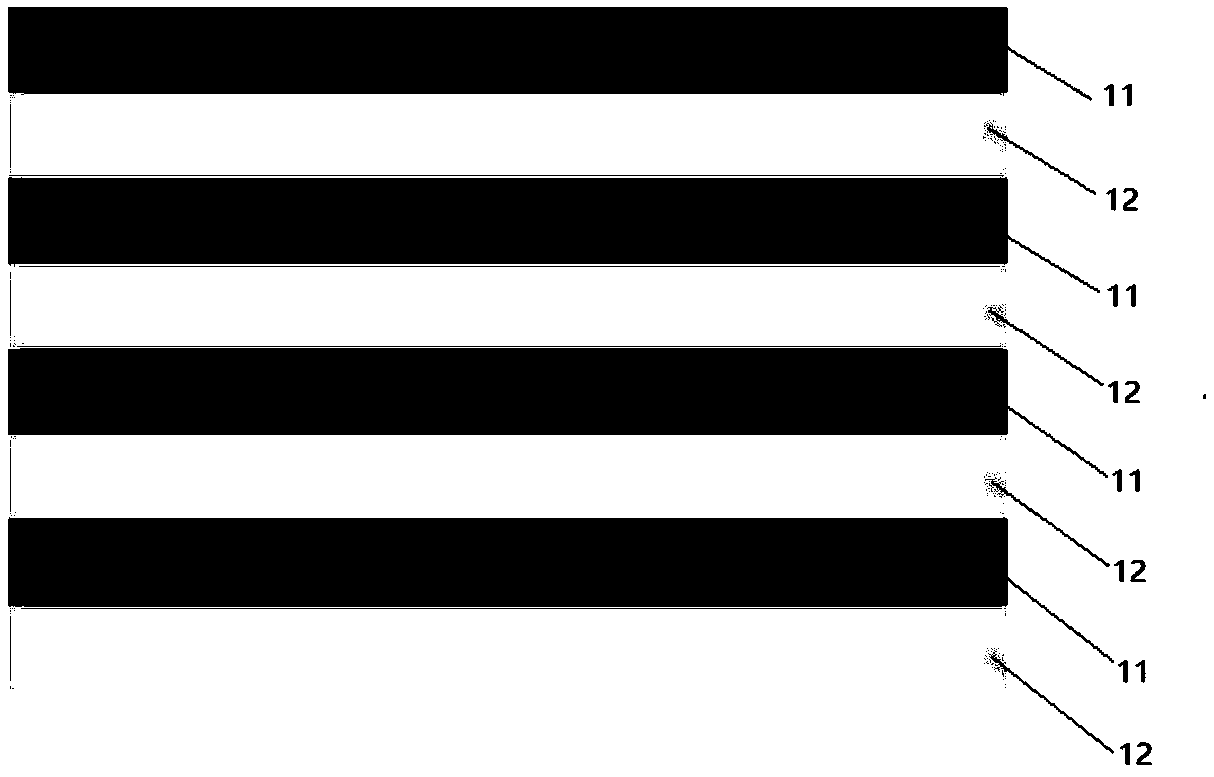

[0040] a. making graphene composite film 4: laminating graphene film 11 and polymer binder 12 to form graphene composite film 4;

[0041] b. Lamination of the graphene composite film 4 and the needle-shaped array heat conduction column 3: through a hot press, the graphene composite film 4 is extruded through a set of needle-shaped array heat conduction columns processed at the position corresponding to the heat source of the heat dissipation cavity 2 3. Combine the longitudinal cylindrical surface of the needle-shaped array heat conduction column 3 with the graphene composite film 4 through heat conduction.

[0042] Wherein, the polymer adhesive 12 adopts epoxy resin;

[0043] Wherein, the graphene film 11 and the polymer adhesive 12 are stacked at even intervals, and are bonded in the heat dissipation cavity 2 through the underlying polymer adhe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com