Processing method of almond juice beverage

A processing method and almond technology, which are applied in the field of vegetable protein beverage processing, can solve the problems of easy oxidation of unsaturated fatty acids and loss of nutrients in wild almonds, and achieve the effect of retaining nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

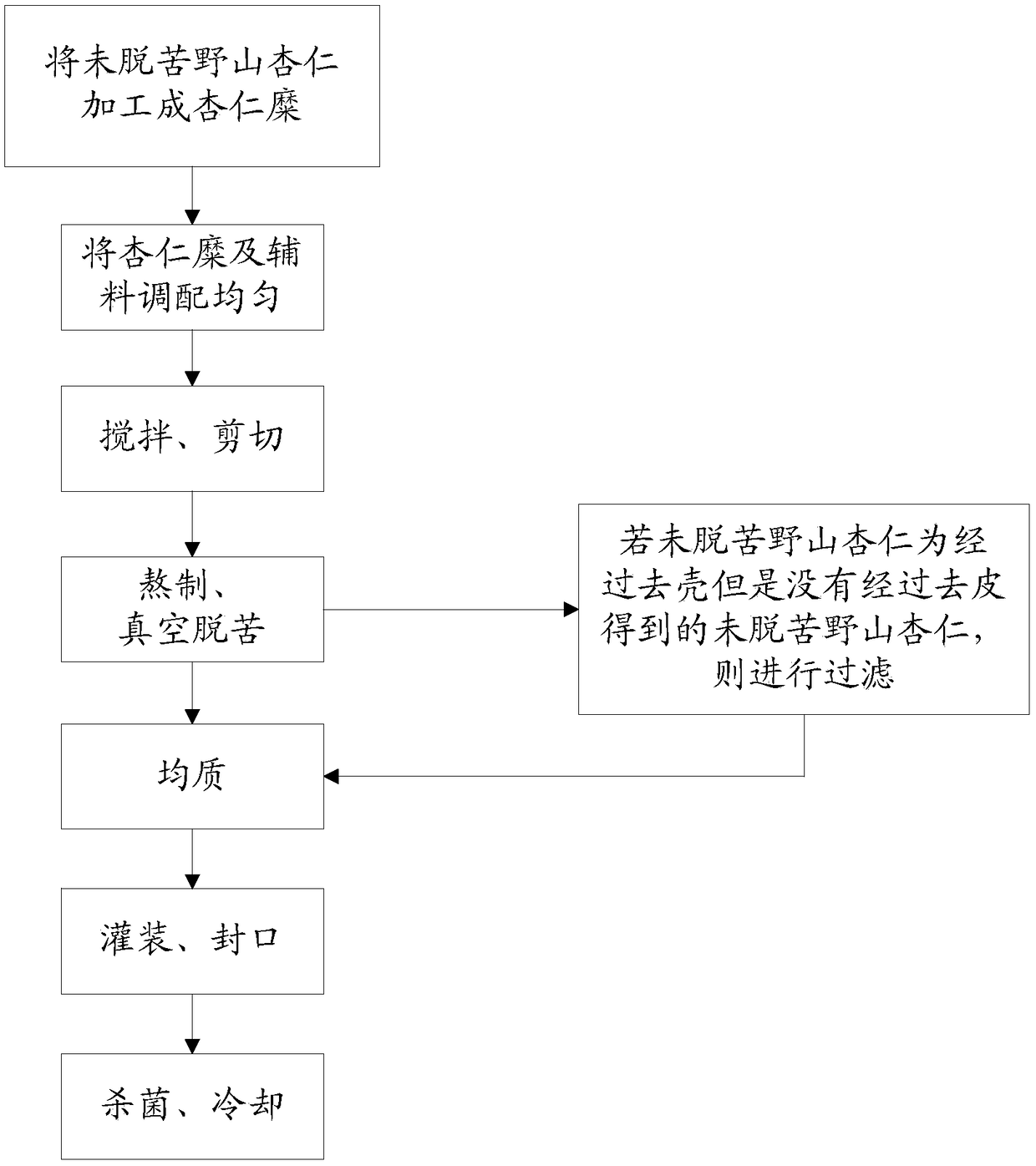

Method used

Image

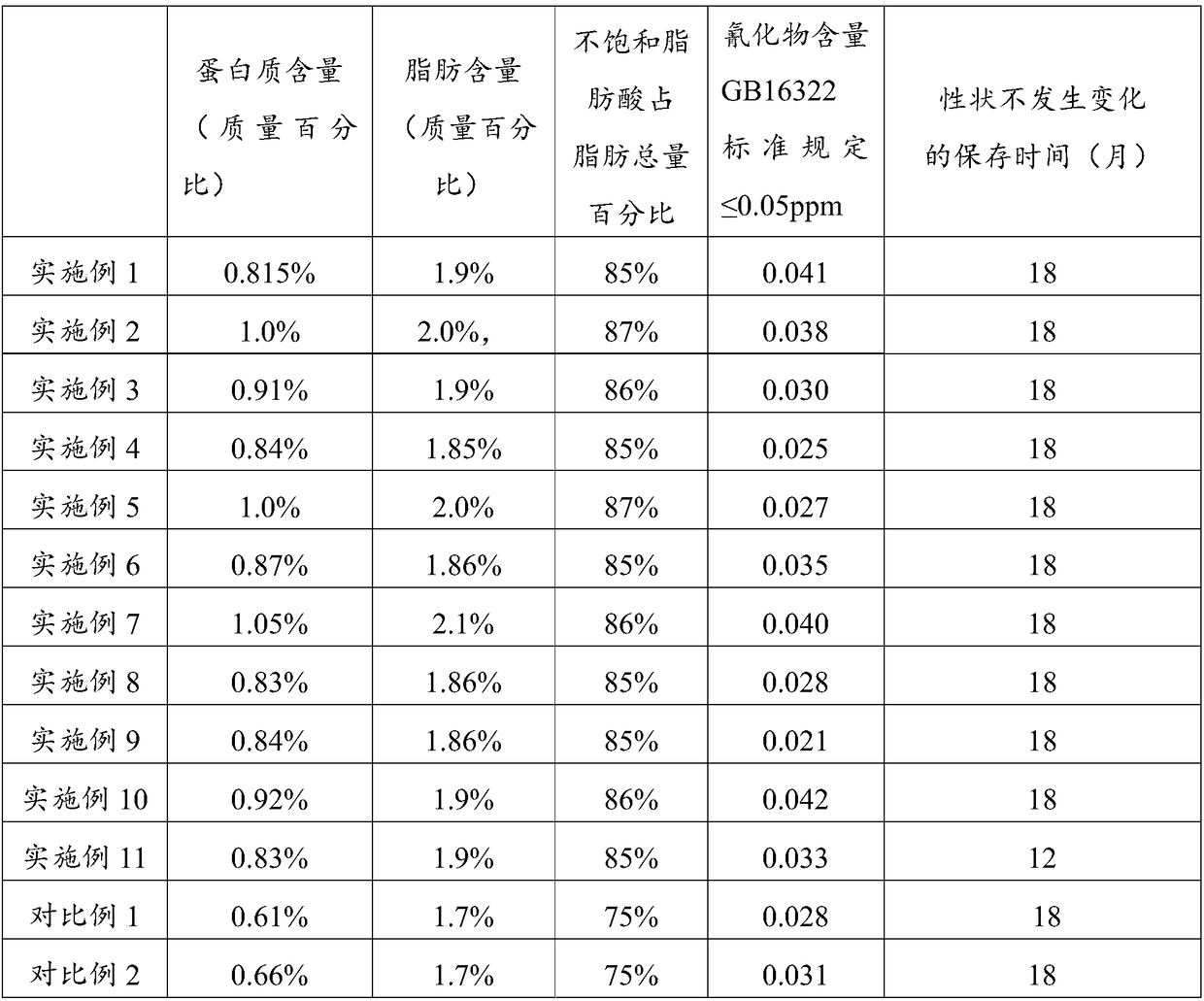

Examples

Embodiment 1

[0071] The present embodiment provides a kind of processing method of almond milk beverage, comprises the following steps:

[0072] In step (1), select almonds with full grains, no insects, and no mildew, and peel off the shells to obtain unbittered wild almonds; grind the obtained undebittered wild almonds into a mince with a particle size of 55 microns to obtain almonds Mince, keep the temperature of almond mince at 50°C during the grinding process;

[0073] Step (2), successively add 120Kg ground almonds, 300Kg sucrose, 6Kg polyglycerol fatty acid ester, 4Kg glyceryl monostearate, 8Kg sodium bicarbonate, 1Kg citric acid and 1000Kg water into the mixing tank and mix evenly;

[0074] Step (3), stirring and shearing the mixture obtained in step (2), emulsifying the mixture;

[0075] Step (4), transfer the emulsified mixture obtained in step (3) to a boiling tank, add 4000Kg of water, heat to boiling and keep for 5 minutes for boiling, and boil under the vacuum degree of -0.05...

Embodiment 2

[0084] The present embodiment provides a kind of processing method of almond milk beverage, comprises the following steps:

[0085] In step (1), select almonds with full grains, no insects, and no mildew, and peel off the shells to obtain unbittered wild almonds; beat the obtained undebittered wild almonds into a minced material with a particle size of 60 microns to obtain almonds Mince, keep the temperature of almond mince at 50°C during the beating process;

[0086] In step (2), 160Kg ground almonds, 100Kg xylitol, 0.5Kg cyclamate, 6Kg sucrose fatty acid ester, 5Kg sodium stearoyl lactylate, 7.5Kg sodium carbonate, 2Kg sodium citrate and 1500Kg water are added to the mixing tank and mixed uniform;

[0087] Step (3), stirring and shearing the mixture obtained in step (2), emulsifying the mixture;

[0088] Step (4), transfer the emulsified mixture obtained in step (3) to a boiling tank, add 4000Kg of water, heat to boiling and keep for 5 minutes for boiling, and boil under t...

Embodiment 3

[0097] The present embodiment provides a kind of processing method of almond milk beverage, comprises the following steps:

[0098] In step (1), select almonds with full grains, no insects, and no mildew, and peel off the shells to obtain unbittered wild almonds; grind the obtained undebittered wild almonds into a mince with a particle size of 50 microns to obtain almonds Mince, keep the temperature of almond mince at 50°C during the grinding process;

[0099] In step (2), 150Kg ground almonds, 50Kg sucrose, 1Kg sucralose, 30Kg maltitol, 6Kg sucrose fatty acid ester, 5Kg sodium stearoyl lactylate, 7.5Kg sodium carbonate, 1Kg citric acid and 1000Kg water were added to the blending tank in turn well mixed;

[0100] Step (3), stirring and shearing the mixture obtained in step (2), emulsifying the mixture;

[0101] Step (4), transfer the emulsified mixture obtained in step (3) to a cooking tank, add 4000Kg of water, heat to boiling and keep for 8 minutes to cook, and under the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com