Cleaning machine for solar battery panel

A solar panel and cleaning machine technology, applied in the field of cleaning, can solve problems such as different cleaning methods, accumulation of bird droppings, dust, and easy adhesion on the surface of the battery panel, and achieve the effect of improving the effect of scrubbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

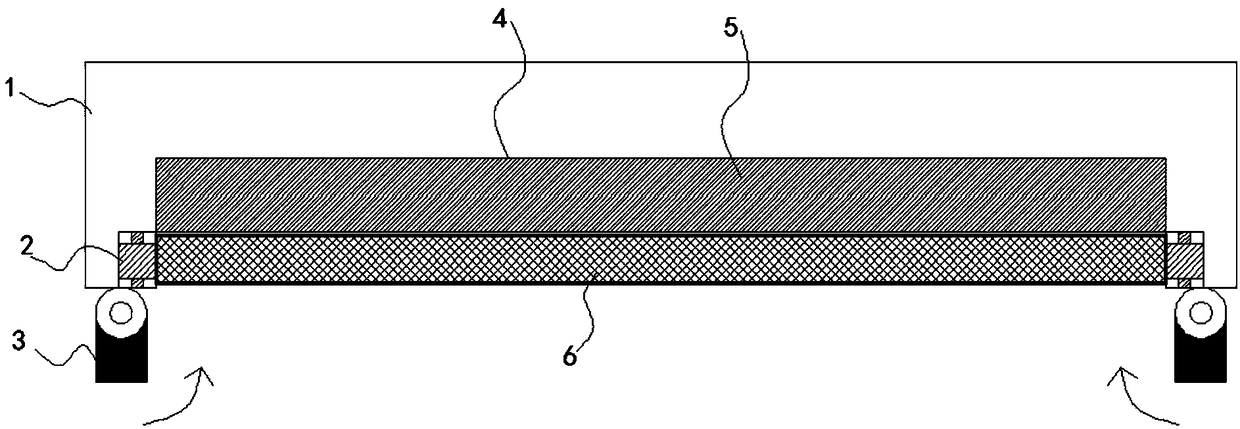

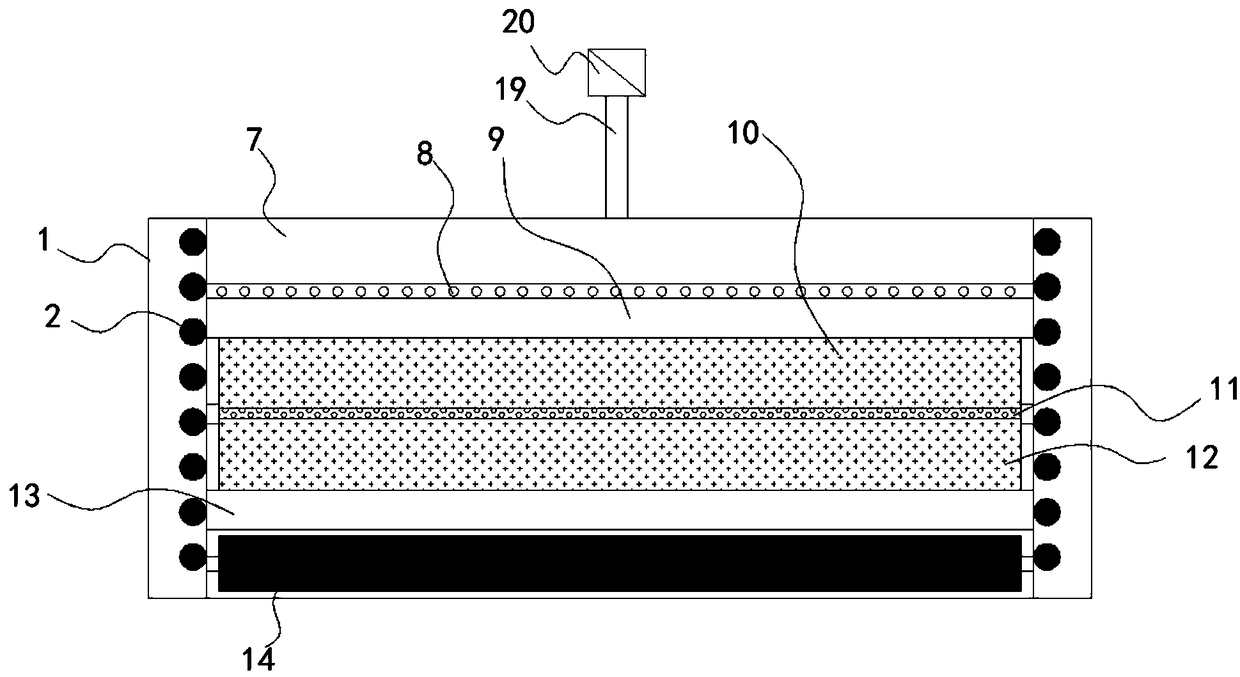

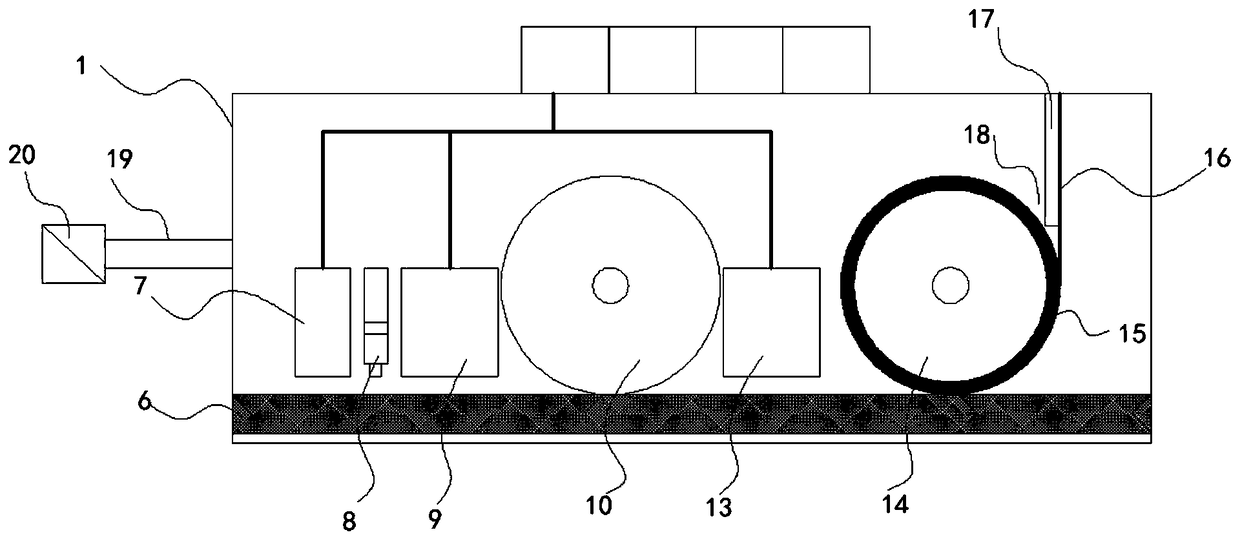

[0032] Such as figure 1 , 2 , 3, 4 and 5, a cleaning machine for solar panels, including:

[0033] The vehicle body 1 that can move along the surface of the solar cell panel 6, for the movable body 1, the bottom surface of the vehicle body is provided with a groove 4, the groove 4 is used to cooperate with the solar cell panel 6, the size of the groove 4 It is arranged to match with the solar battery panel 6 so that the solar battery panel 6 can be placed in the groove 4, and the installation space for installing the cleaning assembly 5 is preset in the groove 4, and the installation space and the solar battery Corresponding to the plate 6, the solar cell panel 6 is placed behind the groove, the cleaning assembly 5 is corresponding to the surface of the solar cell panel 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com