Boron-containing phenolic resin microspheres and preparation method thereof

A technology of boron phenolic resin and phenolic resin, which is applied in the field of boron-containing phenolic resin microspheres and its preparation, can solve the problems of large irreversible capacity loss of boron-containing phenolic resin microspheres, achieve reduced irreversible capacity loss, good sphericity, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] One embodiment of the present invention discloses a preparation method of boron-containing phenolic resin microspheres, comprising the following steps:

[0025] Step 1: mixing boron-containing thermoplastic phenolic resin, thermosetting phenolic resin and ethanol in proportion to form a resin solution;

[0026] Step 2: Put the resin solution, surfactant and solvent into a container, stir and react at a predetermined temperature, and after the reaction is completed, wash and dry the precipitate to obtain spherical boron-containing phenolic resin particles.

[0027] In some preferred embodiments, in Step 1, the mass ratio of boron-containing thermoplastic phenolic resin, thermosetting phenolic resin and ethanol is 1:(2-2.5):2. In step 2, the surfactant is sodium lauryl sulfate; the mass ratio of resin solution, surfactant and solvent is 1: (0.016-0.032): (2.380-4.760); the predetermined temperature is 150-160 °C; the stirring reaction is 400-1000rpm constant speed stirri...

Embodiment 1

[0030] First, mix commercial boron-containing thermoplastic phenolic resin, industrial ethanol, and thermosetting phenolic resin at a mass ratio of 1:2:2.5.

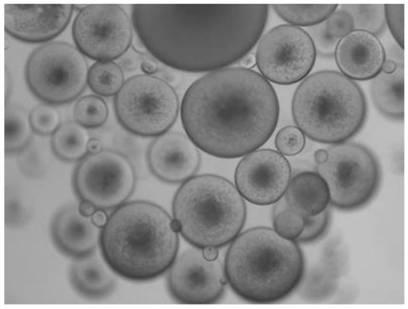

[0031] Next, put the above prepared solution, sodium lauryl sulfate, and liquid paraffin directly into the beaker with a mass ratio of 1:0.032:2.380, stir at a constant speed of 500 rpm, heat up to 150°C, and keep the temperature for 90 minutes. After the reaction stops, , the boron phenolic resin microsphere particle size obtained by the method is between 40-90 μm. Its optical micrograph is shown in figure 1 , it can be seen that its sphericity is good.

Embodiment 2

[0033] First, mix commercial boron-containing thermoplastic phenolic resin, industrial ethanol, and thermosetting phenolic resin at a mass ratio of 1:2:2.5.

[0034] Next, put the above prepared solution, sodium lauryl sulfate, and liquid paraffin directly into the beaker with a mass ratio of 1:0.020:3.170, stir at a constant speed of 500 rpm, heat up to 150°C, and keep the temperature for 90 minutes. After the reaction stops, , the particle size of boron phenolic resin microspheres obtained by this method is about 370 μm in D50.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com