Solid Lubricating Coating Apparatus for Gear Tooth Surfaces

A technology of solid lubricating coatings and gear teeth, which is applied in coatings, metal material coating processes, gaseous chemical plating, etc., can solve the problems of high air tightness requirements for equipment, difficulties in implementing experimental operations, and the thickness of coatings on gear tooth surfaces. Inhomogeneity and other problems, to achieve the effect of improving coating efficiency, improving coating quality, and easy to evenly distribute

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

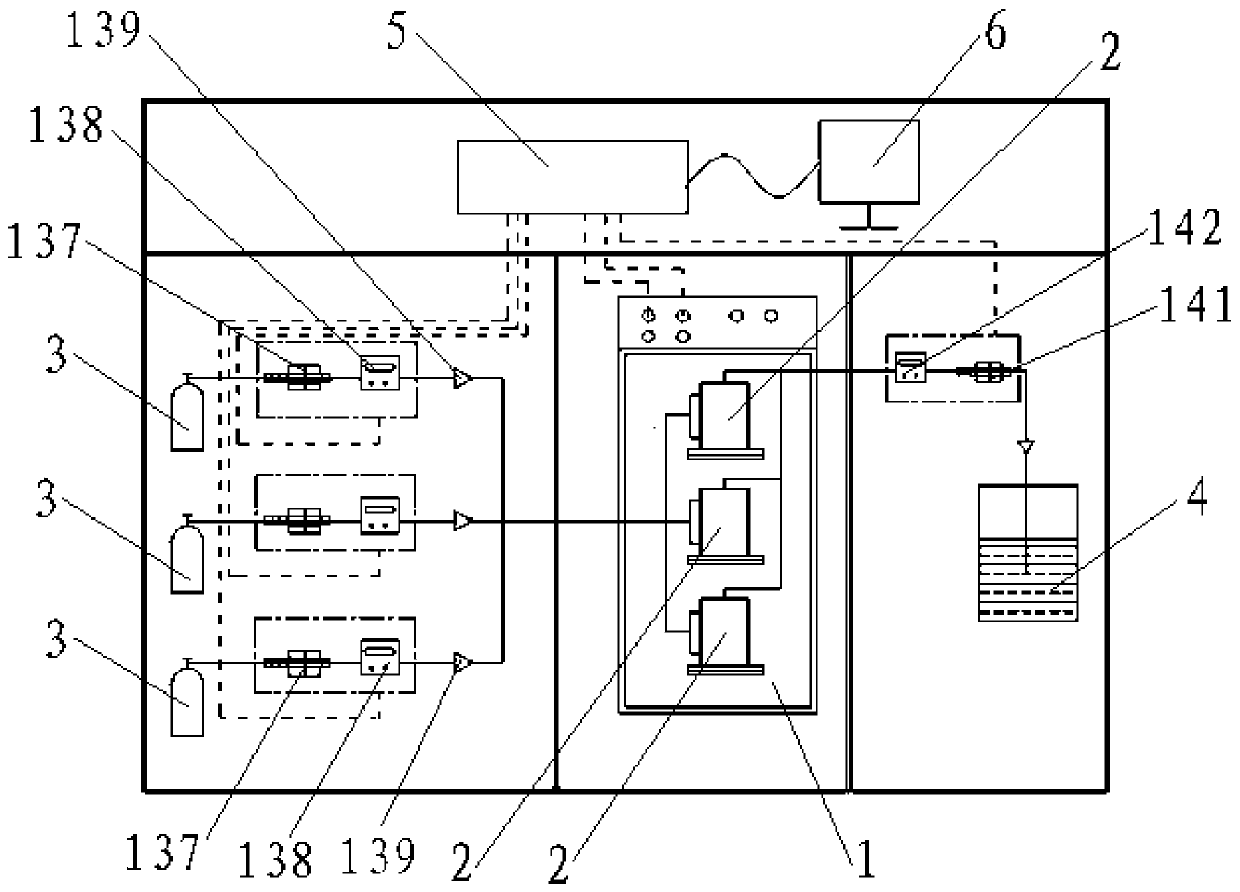

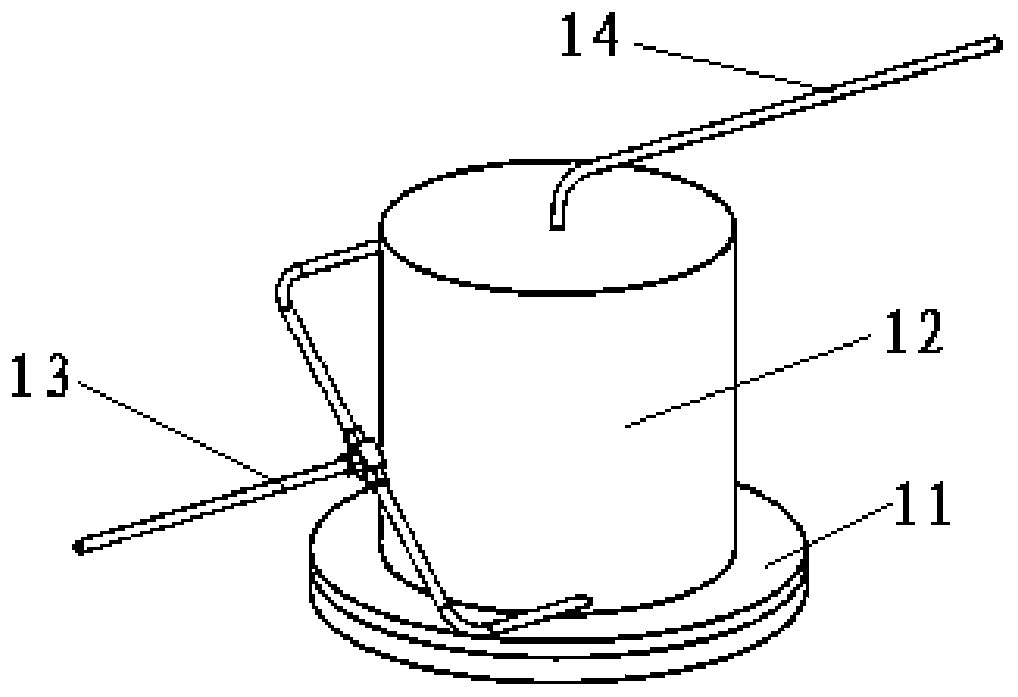

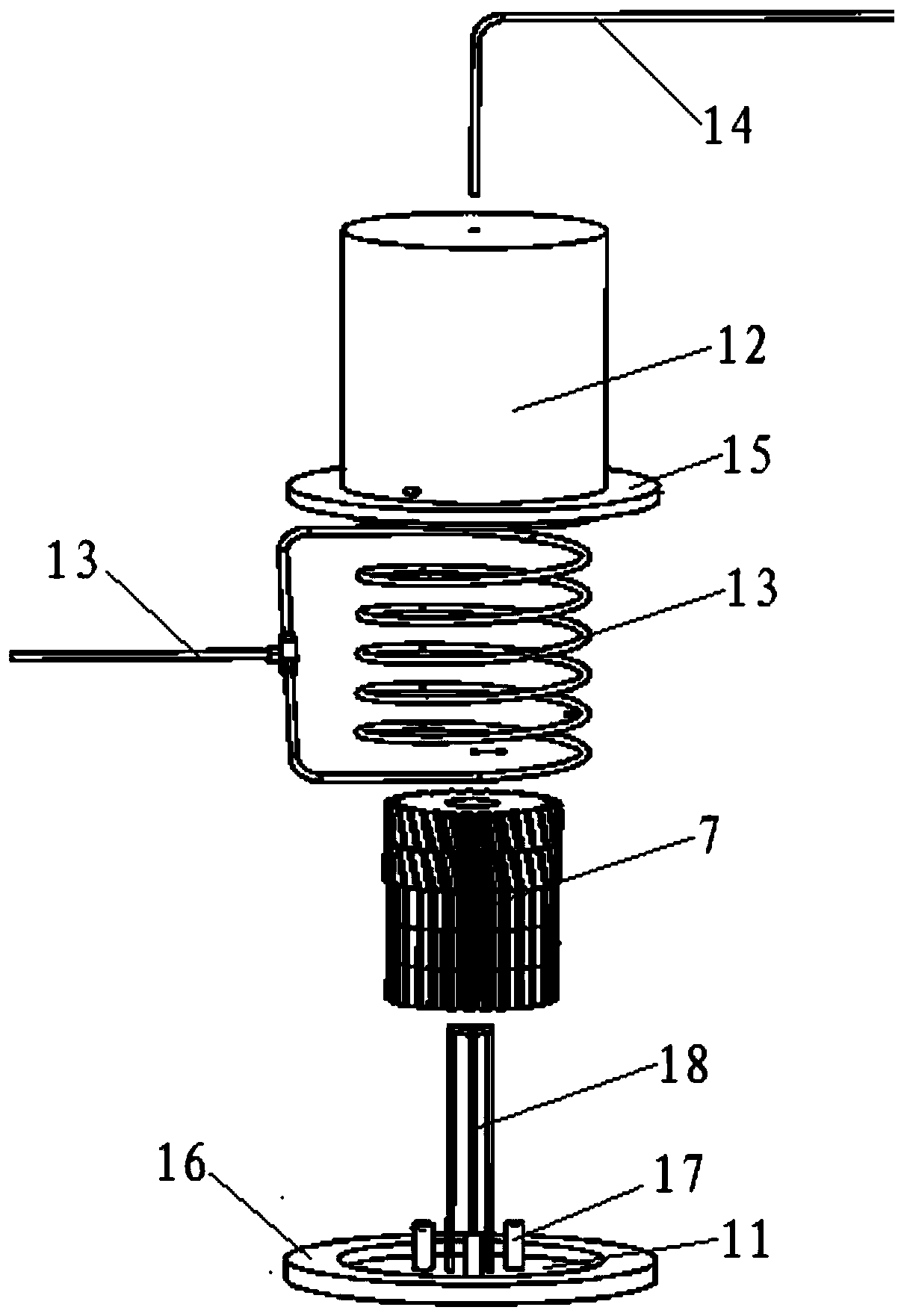

[0028] Such as figure 1 , figure 2 , image 3 As shown, the solid lubricating coating coating device for gear tooth surfaces of the present invention includes a heating furnace 2, a gas storage tank 3, a control system, an exhaust gas treatment assembly 4 and at least one reactor assembly 1, and all reactor assemblies 1 are provided with In the heating furnace 2, a reaction chamber is arranged in the reactor assembly 1, and the reaction chamber is a closed space relative to the heating furnace 2. The reaction chamber is composed of a chassis 11 and an outer casing 12, and the outer casing 12 is detachably arranged on the chassis 11, the gas storage tank 3 and the tail gas treatment assembly 4 are connected to the reactor assembly 1, and the control system is used to control the operation of the heating furnace 2. The gas storage tank 3 is provided with reaction gas, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com