Environment-friendly type automatic quartz sand drying device and quartz sand drying method

A drying device, quartz sand technology, applied in drying, dryer, sand drying and other directions, can solve the problems of small contact area between quartz sand and airflow, harmful to human health, low drying efficiency, etc. The effect of popularization and application, less environmental pollution and high drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

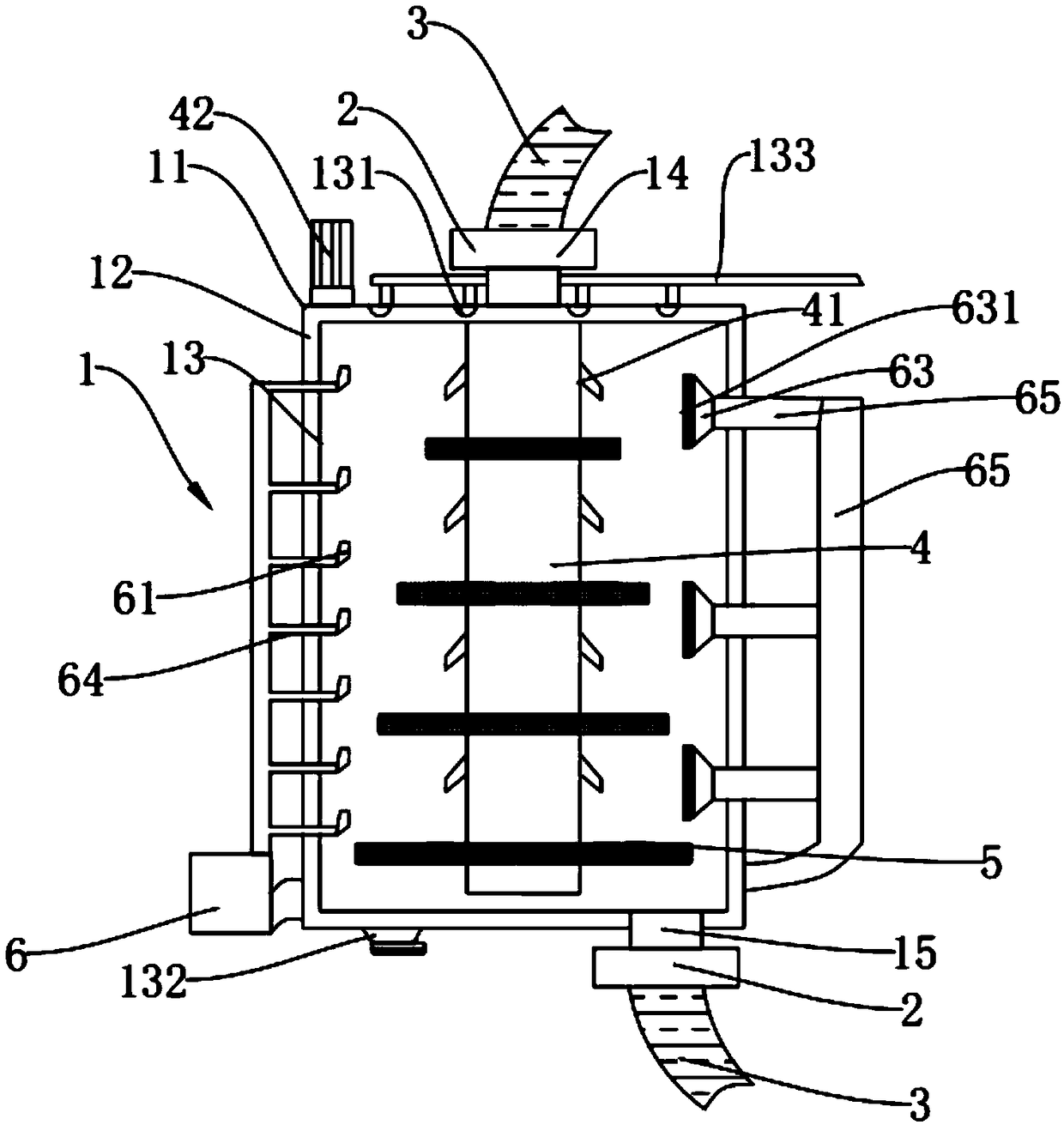

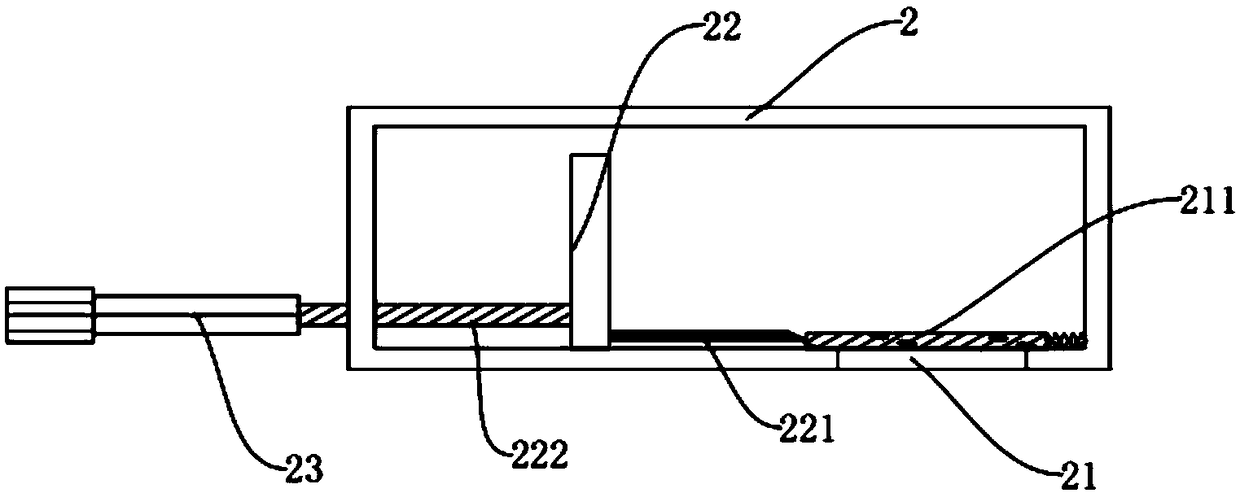

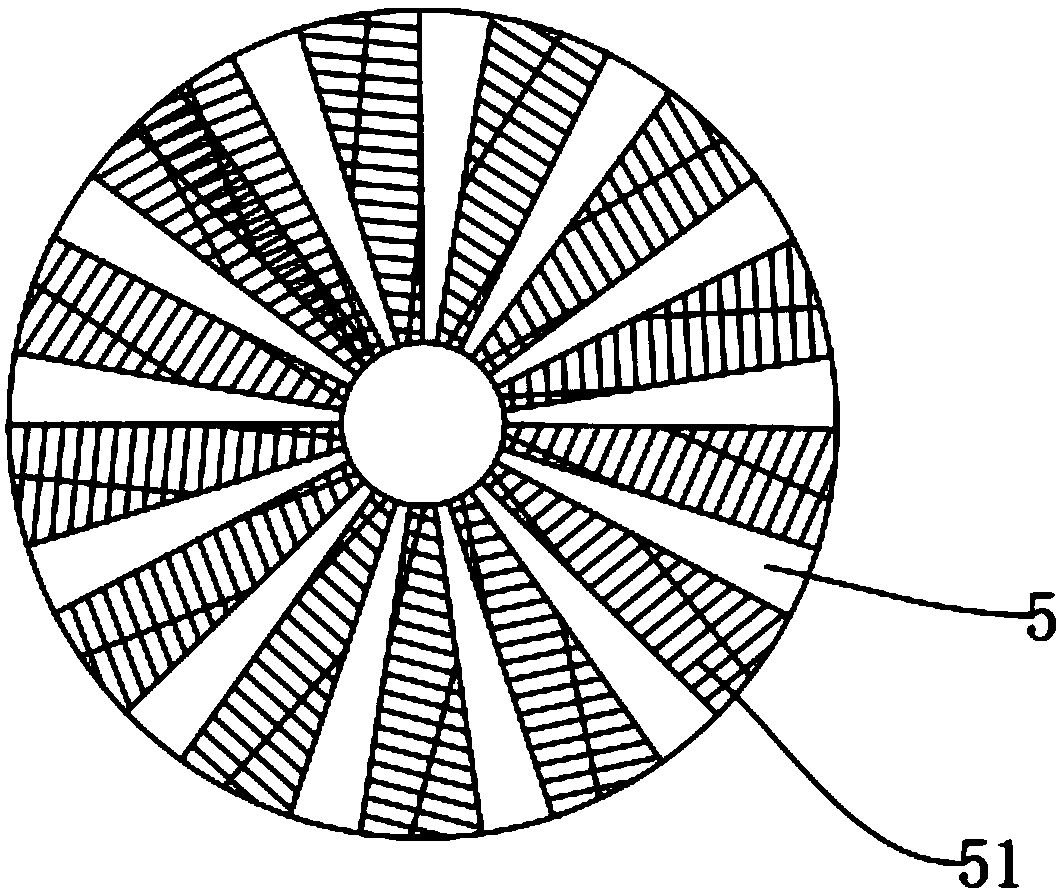

[0024] Such as Figure 1 to Figure 3 Shown is an environment-friendly automatic drying device for quartz sand, which includes a drying chamber 1. The side walls of the drying chamber include an outer wall 11, an inner wall 12, and an intermediate chamber 13 between the outer wall 11 and the inner wall 12, wherein the drying The top of the drying chamber 1 is provided with a material inlet 14 and the bottom is provided with a material outlet 15, and both the inlet 14 and the outlet 15 are provided with a dust removal chamber 2 and a material chute 3 connected to the dust removal chamber 2; the inside of the drying chamber 1 The feeding cylinder 4 connected to the feeding port 14 is set, and some distributing disks 5 are arranged around the feeding cylinder 4. The distributing disks 5 are arranged in the order of diameter from small to large in the vertical direction. The feed cylinder body 4 is provided with a number of material distribution openings 41 corresponding to the mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com