Automatic test system of T/R assembly

A component and test signal technology, applied in the transmission system, electrical components, transmission monitoring, etc., can solve the problems of cumbersome test operation and equipment maintenance, heavy preparation workload, low production efficiency, etc., to ensure test work efficiency and convenient maintenance , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

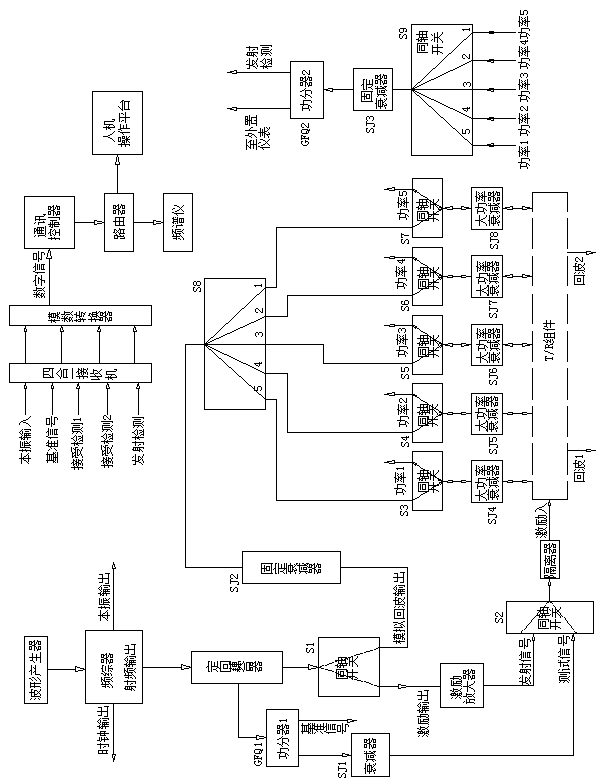

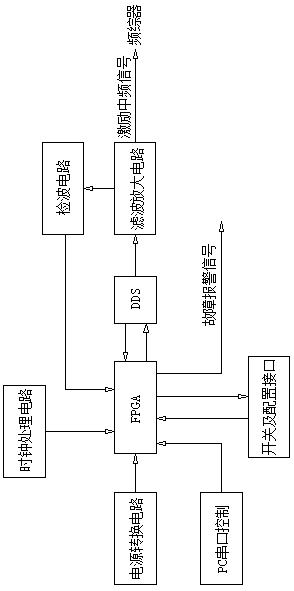

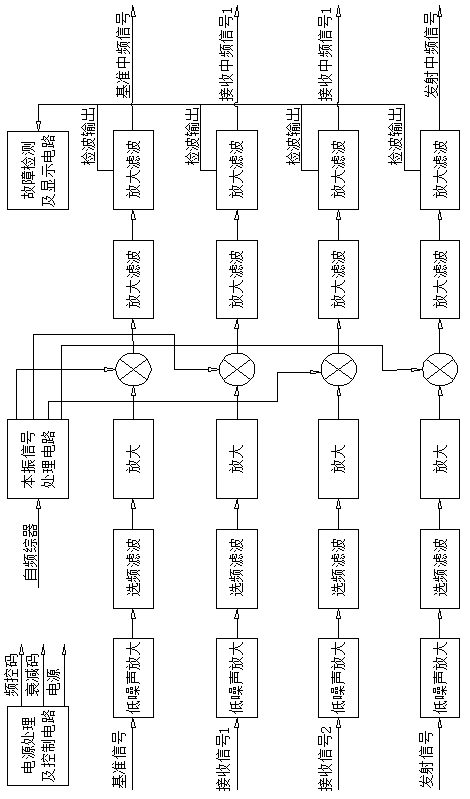

[0025] The implementation of this automatic T / R component testing system will be described in further detail below in conjunction with the accompanying drawings (see Figure 1-7 ):

[0026] An automatic T / R component test system, which includes a frequency synthesizer, a waveform generator, a four-in-one receiver, a communication controller, an analog-to-digital converter, a directional coupler, a coaxial switch, a power divider, a router, a large Power attenuator, power module, ventilation and cooling system, man-machine interface, independent software;

[0027] The waveform generator is a direct digital frequency synthesizer DDS, which generates intermediate frequency test signals and excitation signals, and outputs them to the frequency synthesizer after filtering and amplifying;

[0028] The frequency synthesizer includes a clock signal source, a local oscillator signal source, and an excitation signal source; the clock signal source provides a working clock of 15MHz for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com