Ruthenium-phosphorous co-modified compound catalyst and preparation method thereof

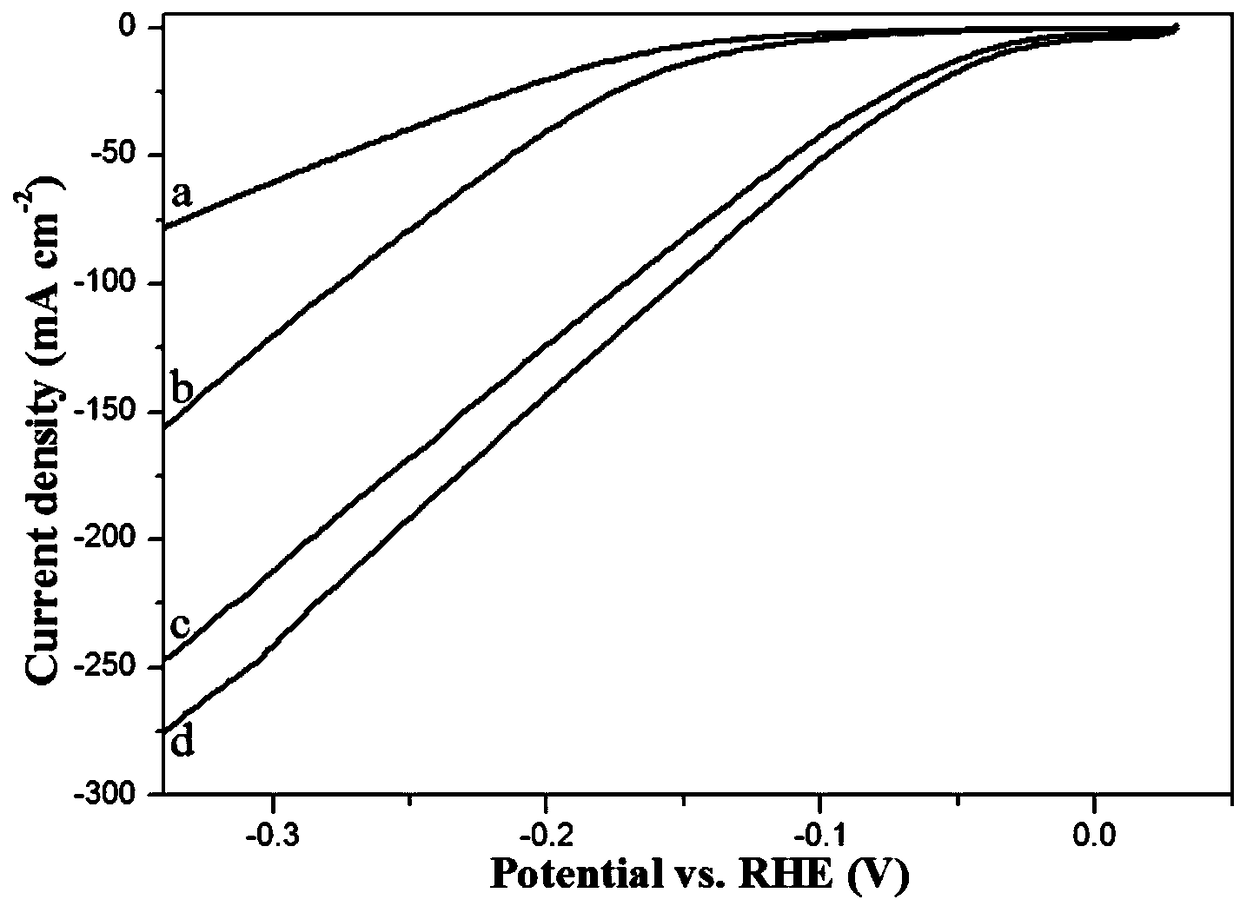

A composite catalyst and co-modification technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problem that the hydrogen evolution activity cannot be compared with that of Pt noble metal catalysts, and achieve large industrial application prospects. Production cost reduction, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

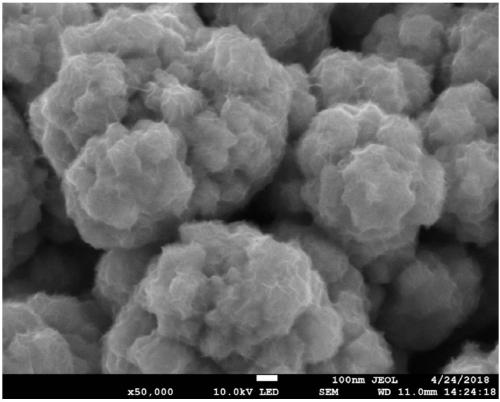

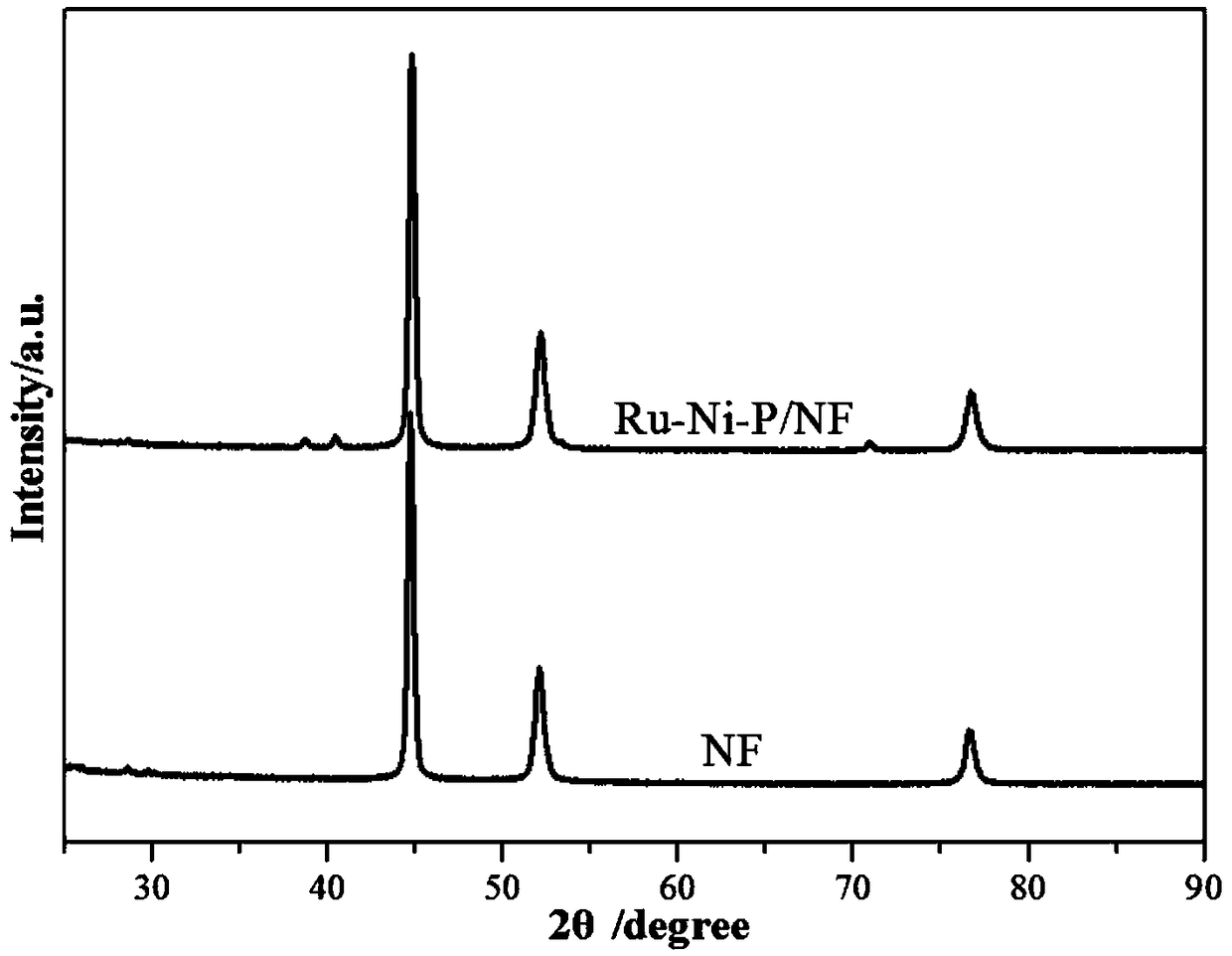

[0035] A ruthenium-phosphorus co-modified nickel composite catalyst includes ruthenium element and nickel phosphide, and the ruthenium element is embedded in the nickel phosphide through an electrochemical method.

[0036] A preparation method of a ruthenium-phosphorus co-modified nickel composite catalyst specifically includes the following steps:

[0037] (1) Put the cleaned foamed nickel into a reactor containing 15% hydrogen peroxide by mass, with an oxidation temperature of 150°C and an oxidation time of 16h, and obtain nickel oxide foamed nickel by hydrothermal oxidation and etching;

[0038] (2) Using the foamed nickel with rough surface and nickel oxide obtained in step (1) as the cathode and carbon rod as the anode, prepare 50mmol / L sodium citrate, 10mmol / L hydrochloric acid, 50mmol / L ammonium sulfate, 10mmol / L A mixed solution of ruthenium trichloride and 100mmol / L sodium hypophosphite was used as an electrolyte, reacted for 2h under a constant potential condition of -1.2V,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com