Preparation method and application of highly dispersed graphene/Fe-based metal organic framework composite material electrochemical sensor

An organic framework and composite material technology, applied in the field of chemistry, can solve the problems of low dispersion, insufficient performance of graphene, easy to agglomerate into large particles, etc., and achieve the effects of low detection limit, low production cost and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

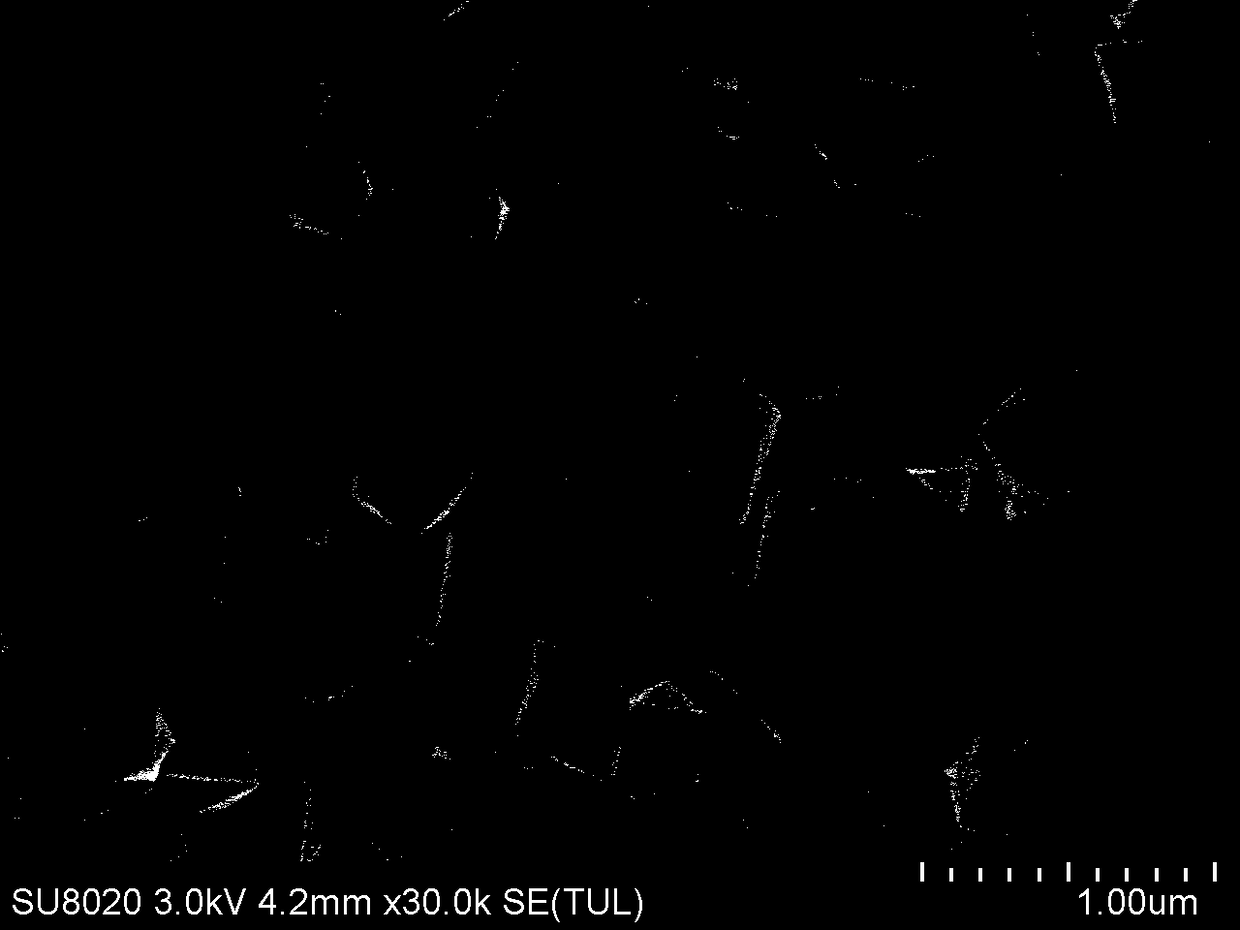

[0024] For the convenience of comparison, the preparation of Fe-based metal-organic framework was carried out in this example: Fe(NO 3 ) 3 9H 2 O200 mg, organic ligand terephthalic acid 400 mg, and PVP 1g were added to the solvent N,N-dimethylformamide, stirred evenly at room temperature, transferred to a reaction kettle, and the reaction temperature was controlled at 100°C for 11 h , after centrifugation, washing with absolute ethanol three times, and vacuum drying at 30°C, a hexagonal bipyramidal Fe-MOF with regular morphology was obtained; the morphology of the synthesized material was characterized by scanning electron microscopy, as shown in figure 2 shown. figure 2 The regular hexagonal bipyramidal Fe-MOF structure is clearly shown, indicating that the synthesis method used in the present invention well maintains the typical structure of Fe-MOF.

[0025] The preparation method of the non-enzymatic hydrogen peroxide electrochemical sensor of highly dispersed graphene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com