Laser auxiliary electric jetting in-situ printing manufacturing method

A printing manufacturing and laser-assisted technology, which is applied in the direction of additive manufacturing, manufacturing tools, and manufacturing auxiliary devices, can solve problems such as limited spatial layout accuracy, weak bonding performance between functional units and substrates, and excessively large manufacturing scale of functional units. Effects of sensitivity and stability, reduced feature size, improved dimensional accuracy and bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

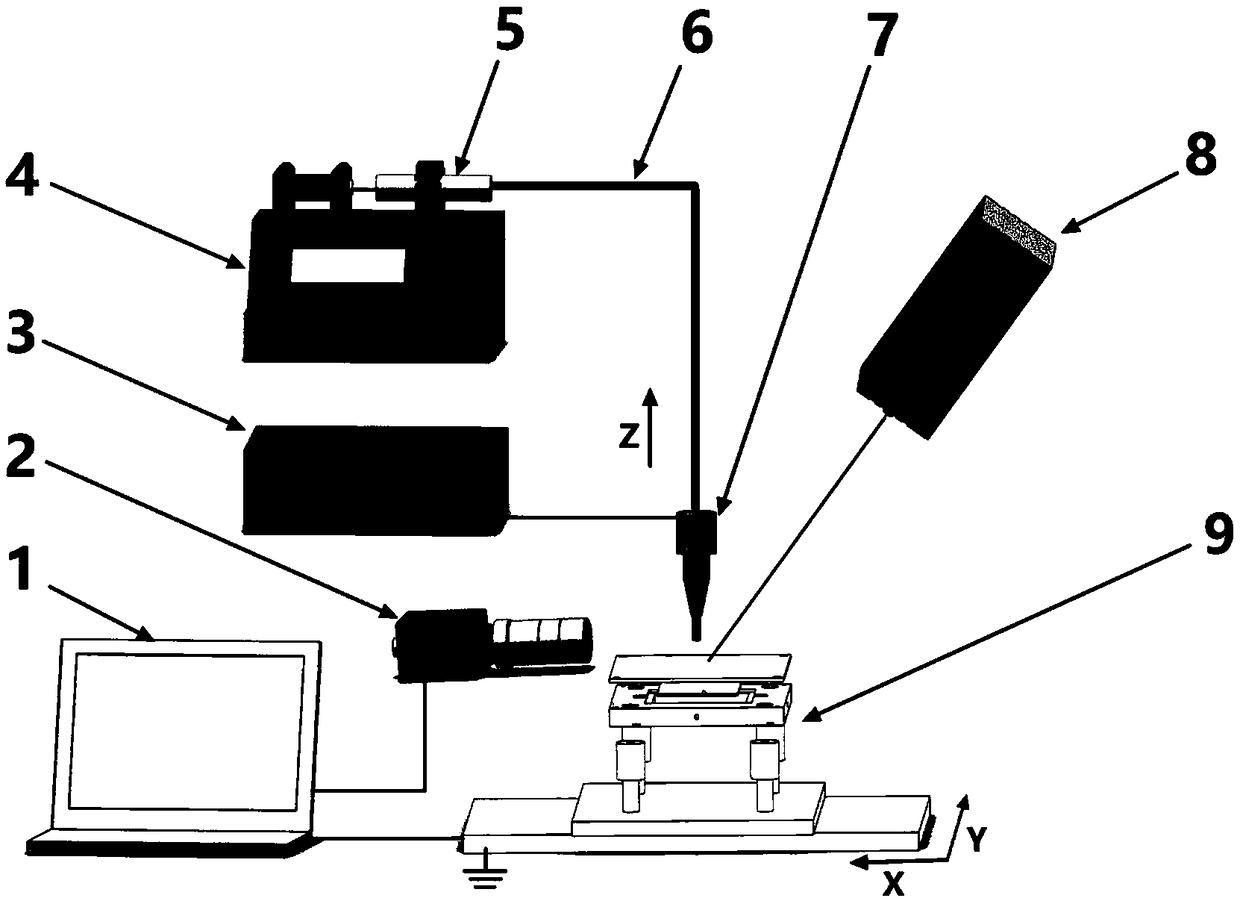

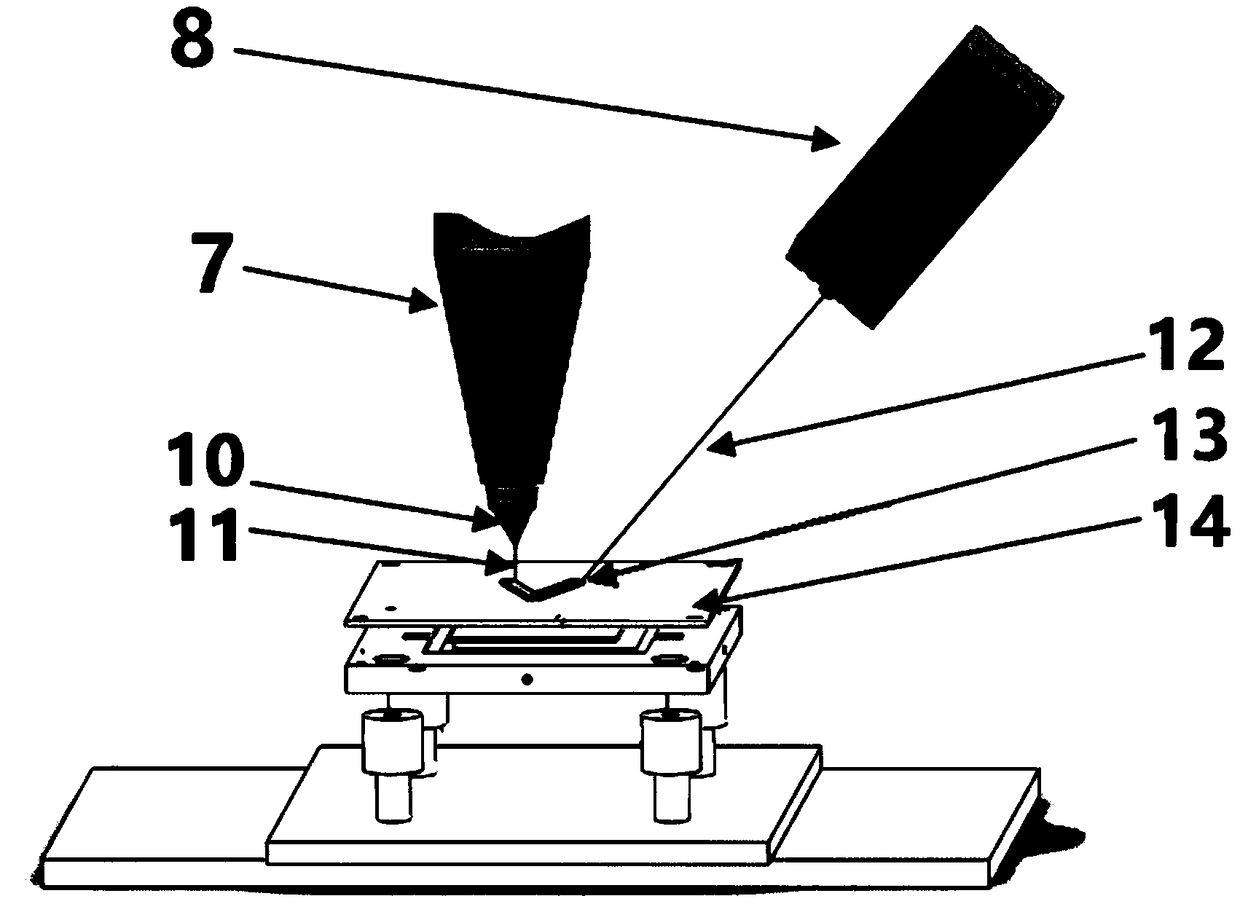

[0026] The present invention is further described in combination with technical solutions and drawings. The laser-assisted electrospray in-situ printing manufacturing device of the embodiment includes an electrospray printing module, a laser in-situ functionalization processing module, and the like.

[0027] The precision syringe 5 is installed on the micro-injection pump 4, and "ZnO suspension ink" is housed inside. The injection needle 7 is connected to the precision syringe 5 through the conduit 6, the high-voltage power supply 3 outputs 1200V, the positive output terminal is connected to the injection needle 7, and the negative electrode is connected to the printing plate 14. The needle 7 flows out and under the action of the electric field, a stable Taylor cone 10 is formed at the needle outlet, and a stable fine jet 11 is ejected to print on the substrate, and the X / Y axis motion platform drives the printing plate 14 according to the predetermined The motion track moves ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spot diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com