A kind of infrared transparent ceramic material and preparation method thereof

A transparent ceramic and infrared technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of harsh service environment of infrared windows/fairings, increased aerodynamic force and aerodynamic heat, etc. Growth rate, effect of grain size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0097] Examples 1-4 use the above-mentioned solid-phase method to synthesize the above-mentioned nanocomposite powder, and the specific steps are similar to the above-mentioned steps, which are mainly realized by adjusting the process parameter conditions of each step. Embodiments 1-4 adopt the above-mentioned solid-phase method to synthesize the process conditions of the above-mentioned nanocomposite powder specifically as shown in Table 1 below:

[0098] Table 1: The technological parameter condition of embodiment 1-4

[0099]

Embodiment 5-8

[0101] Examples 5-8 use the above-mentioned co-precipitation method to synthesize the above-mentioned nanocomposite powder, and the specific steps are similar to the above-mentioned steps, which are mainly realized by adjusting the process parameter conditions of each step. Examples 5-8 The process conditions for synthesizing the above-mentioned nanocomposite powders by the above-mentioned co-precipitation method are specifically shown in Table 2 below:

[0102] Table 2: The technological parameter condition of embodiment 5-8

[0103]

Embodiment 9-12

[0105] Examples 9-12 use the above-mentioned homogeneous precipitation method to synthesize the above-mentioned nanocomposite powder, and the specific steps are similar to the above-mentioned steps, which are mainly realized by adjusting the process parameter conditions of each step. Embodiments 9-12 The process conditions for synthesizing the above-mentioned nanocomposite powder by the above-mentioned uniform precipitation method are specifically shown in Table 3 below:

[0106] Table 3: The technological parameter condition of embodiment 9-12

[0107]

[0108]

PUM

| Property | Measurement | Unit |

|---|---|---|

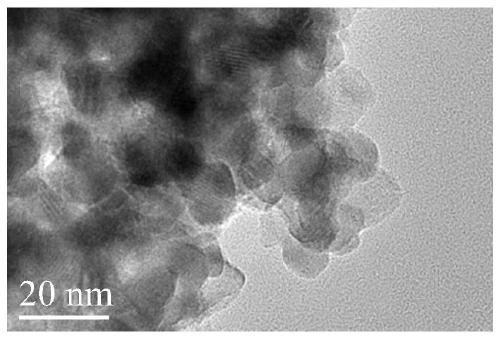

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com