Novel catalyst-free oxidation method for cyclooctane

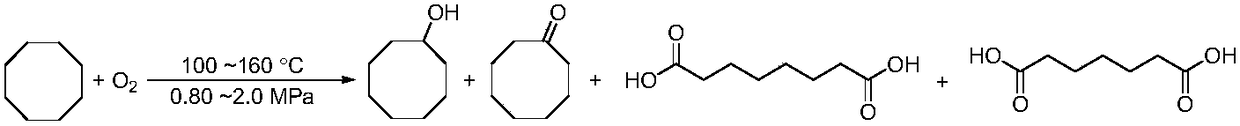

A cyclooctane and catalyst technology, which is applied in the field of cyclooctane catalyst-free oxidation, can solve problems such as environmental pollution, increased cyclooctane oxidation cost, unfavorable large-scale development of downstream products, etc., to achieve simple operation, prevent transition metal pollution, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] In a 100 mL stainless steel autoclave with a tetrafluoroethylene liner, feed 50.0 g of cyclooctane, and close the autoclave. Stir and slowly raise the temperature to 140°C, pass O 2 to 1.2MPa, at 140°C, 1.2MPa O 2 The reaction was stirred under pressure for 8.0 h, stirred and cooled to room temperature in an ice-water bath. The autoclave was turned on, and the obtained reaction mixture was filtered. The obtained solid was washed with 3×10 mL of cyclooctane, and dried in vacuum at 60° C., and the obtained white solid was analyzed by HPLC. The yield of suberic acid was 0.93%, and the yield of pimelic acid was 0.15%. Filtrate the obtained filtrate to rectify under reduced pressure, take 70 ℃ ~ 80 ℃ (20mm Hg) fraction, namely cyclooctanone, GC internal standard method analysis yield 5.68%; take 120 ℃ ~ 130 ℃ (22mm Hg) fraction, namely It is cyclooctyl alcohol, and the yield is 2.46% by GC internal standard analysis; at the same time, unreacted cyclooctane is recovered by ...

Embodiment 2

[0015] In a 100 mL stainless steel autoclave with a tetrafluoroethylene liner, feed 50.0 g of cyclooctane, and close the autoclave. Stir and slowly raise the temperature to 100°C, pass O 2 to 1.2MPa, at 100°C, 1.2MPa O 2 The reaction was stirred under pressure for 8.0 h, stirred and cooled to room temperature in an ice-water bath. The autoclave was turned on, the obtained reaction mixture was filtered, the obtained solid was washed with 3×10 mL cyclooctane, and dried in vacuum at 60° C., and the obtained white solid was analyzed by HPLC, and the yield of suberic acid was 0.0%, and the yield of pimelic acid was 0.0%. Filtrate the obtained filtrate to rectify under reduced pressure, take 70 ℃ ~ 80 ℃ (20mm Hg) fraction, namely cyclooctanone, GC internal standard method analysis yield 4.32%; take 120 ℃ ~ 130 ℃ (22mm Hg) fraction, namely It is cyclooctyl alcohol, and the yield is 0.04% by GC internal standard analysis; at the same time, rectification recovers unreacted cyclooctan...

Embodiment 3

[0017] In a 100 mL stainless steel autoclave with a tetrafluoroethylene liner, feed 50.0 g of cyclooctane, and close the autoclave. Stir and slowly raise the temperature to 160°C, pass O 2 to 1.2MPa, at 160°C, 1.2MPa O 2 The reaction was stirred under pressure for 6.0 h, stirred and cooled to room temperature in an ice-water bath. The autoclave was turned on, and the obtained reaction mixture was filtered. The obtained solid was washed with 3×10 mL of cyclooctane, and dried in vacuum at 60° C., and the obtained white solid was analyzed by HPLC. The yield of suberic acid was 1.85%, and the yield of pimelic acid was 0.87%. Filtrate the obtained filtrate and rectify under reduced pressure, take 70 ℃ ~ 80 ℃ (20mm Hg) fraction, namely cyclooctyl ketone, GC internal standard method analysis yield 6.58%; take 120 ℃ ~ 130 ℃ (22mm Hg) fraction, namely It is cyclooctyl alcohol, and the yield is 1.26% by GC internal standard analysis; at the same time, unreacted cyclooctane is recovere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com