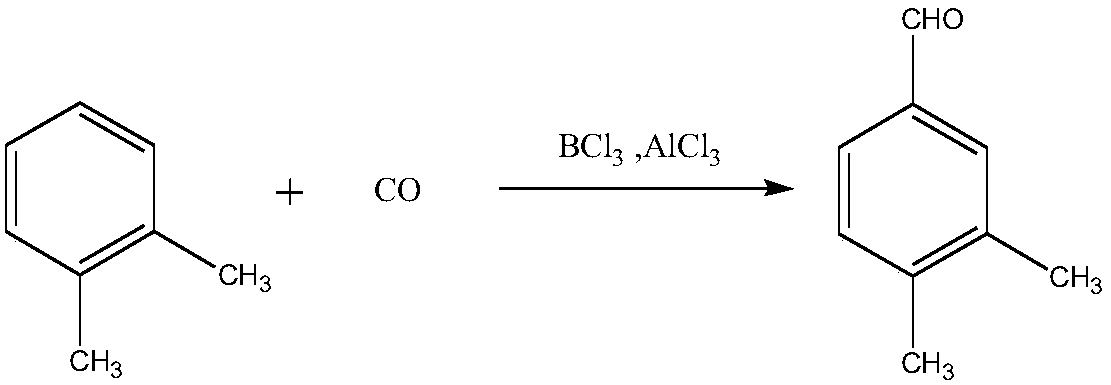

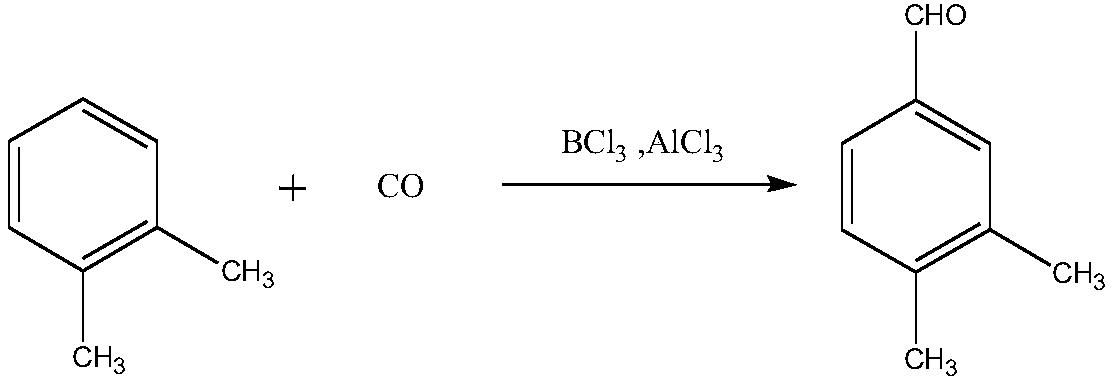

Environment-friendly synthetic method of 3,4-dimethylbenzaldehyde

A technology of dimethylbenzaldehyde and synthetic methods, which is applied in chemical instruments and methods, organic chemistry, physical/chemical process catalysts, etc., can solve the problems of harsh control of reaction conditions and complex catalyst recycling equipment, and achieve low cost, Reduced risk, low yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Add 500g of o-xylene into a 1L high-pressure reactor, replace it with nitrogen, start stirring, add 6.7g of anhydrous aluminum trichloride, cool to -10°C, slowly introduce 117g of boron trichloride, and control the temperature -15 ~-10°C, feed CO until the pressure is 1.0Mpa, when the pressure drops, continue to feed CO to maintain the pressure in the kettle until the pressure no longer drops, indicating the end of the reaction. The material is transferred to the flash evaporator, the temperature of the flash evaporator is controlled to be less than 50°C, and boron trichloride is recovered by double-stage condensation, which can be used in the reaction. The material after flashing is transferred in the flask that 300g ice water is housed again, stirs 30 minutes, leaves standstill layering, water layer extracts once with 50g o-xylene, merges organic layer, carries out vacuum fractionation, reclaims o-xylene can be Apply it to the reaction to obtain 3,4-dimethylbenzaldehy...

Embodiment 2

[0026] As described in Example 1, the difference is that 26.7g of anhydrous aluminum trichloride was added, the preparation steps and conditions were the same as in Example 1, and the resulting yield was 91.2%.

Embodiment 3

[0028] As described in Example 1, the difference is that 66.7g of anhydrous aluminum trichloride was added, the preparation steps and conditions were the same as in Example 1, and the resulting yield was 90.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com