Acrylic emulsion for fiber cement board and preparation method thereof

A technology of acrylic emulsion and fiber cement board, which is applied in the field of acrylic emulsion to improve performance, reduce molecular weight, and increase specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

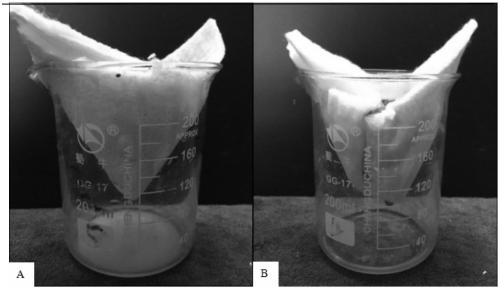

Image

Examples

preparation example Construction

[0036] In addition, the present invention also provides the preparation method of the acrylic acid emulsion for fiber cement board, comprising the following steps:

[0037] 1) Pre-emulsification: Under normal temperature and pressure, mix the anionic emulsifier and 30-40 parts of water in the pre-emulsification tank, fully stir and dissolve, and add the styrene, isooctyl acrylate, acrylic acid, Molecular weight modifier to obtain pre-emulsion;

[0038] 2) Polymerization: add 120-170 parts of water to the bottom of the reaction kettle, heat up to 80-90°C, stir for 20-40 minutes, first drop 0.1-0.8 parts of initiator within 5-10 minutes, and then directly drop Step 1) The obtained pre-emulsion, the dropwise addition time is 150-210 minutes, and the reaction temperature is 80-90°C;

[0039] Wherein, when the pre-emulsion has been added dropwise by 40%-60%, stop adding the remaining pre-emulsion and the remaining initiator, and put the chelating agent of the formula amount into t...

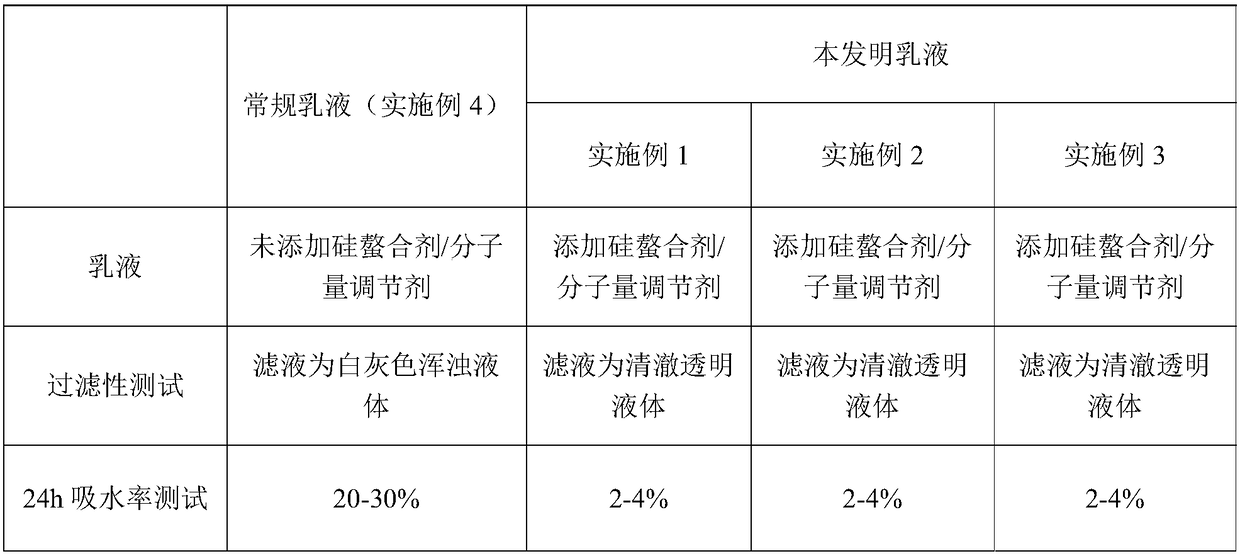

Embodiment 1

[0043] An acrylic emulsion for fiber cement board, comprising the following components in parts by mass: 180 parts of water, 50 parts of styrene, 35 parts of isooctyl acrylate, 0.5 part of acrylic acid, 1 part of anionic emulsifier, and 5 parts of chelating agent 0.5 part of molecular weight modifier, 0.2 part of initiator, 0.1 part of oxidizing agent, and 0.1 part of reducing agent.

[0044] The anionic emulsifier is sodium lauryl sulfate. Described chelating agent is ethylenediaminetetraacetic acid.

[0045] The molecular weight regulator is tertiary dodecyl mercaptan. The initiator is sodium persulfate.

[0046] As an improvement, the oxidizing agent adopts an organic peroxide. The reducing agent is sodium binitrite.

[0047] In addition, the present invention also provides the preparation method of the acrylic acid emulsion for fiber cement board, comprising the following steps:

[0048] 1) Pre-emulsification: Under normal temperature and pressure, mix the anionic emu...

Embodiment 2

[0054] An acrylic emulsion for fiber cement boards, comprising the following components in parts by mass: 260 parts of water, 60 parts of styrene, 45 parts of isooctyl acrylate, 5 parts of acrylic acid, 5 parts of anionic emulsifier, and 10 parts of chelating agent 1.5 parts of molecular weight modifier, 1 part of initiator, 0.5 part of oxidizing agent, and 0.5 part of reducing agent.

[0055] As an improvement, the anionic emulsifier is sodium dodecylbenzenesulfonate. Described chelating agent is aminotriacetic acid.

[0056] The molecular weight regulator is 2,4-diphenyl-4-methyl-1-pentene. The initiator is ammonium persulfate.

[0057] The oxidizing agent adopts organic peroxide. The reducing agent is vitamin C.

[0058] The preparation method of the acrylic acid emulsion that is used for fiber cement board, comprises the following steps:

[0059] 1) Pre-emulsification: Under normal temperature and pressure, mix the anionic emulsifier and 40 parts of water in the pre-e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com