A kind of acrylic acid emulsion for fiber cement board and preparation method thereof

A technology of acrylic emulsion and fiber cement board, which is applied in the field of acrylic emulsion to achieve the effects of wide size distribution, improved performance and excellent primer adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

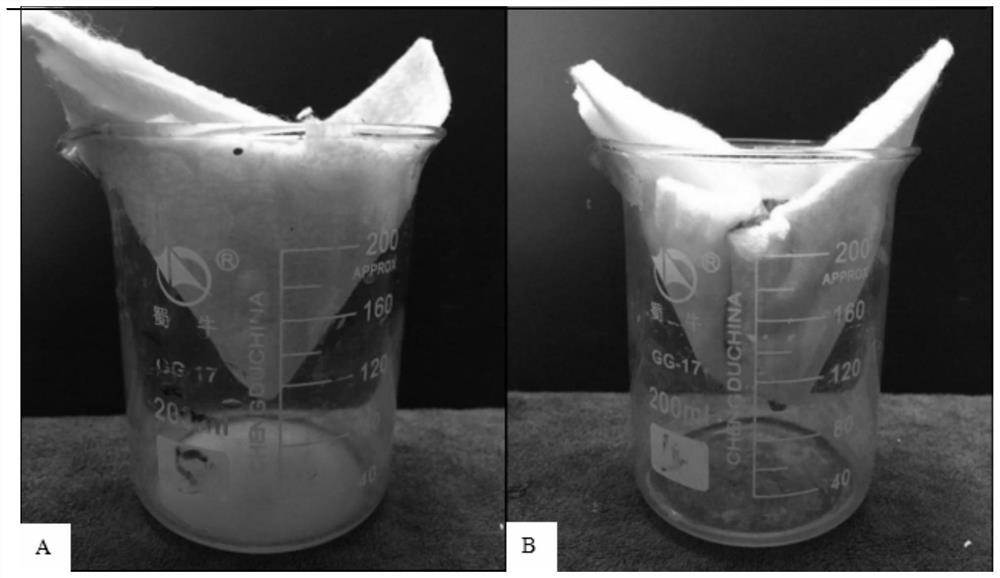

Image

Examples

preparation example Construction

[0036] In addition, the present invention also provides the preparation method of the acrylic acid emulsion for fiber cement board, comprising the following steps:

[0037] 1) Pre-emulsification: Under normal temperature and pressure, mix the anionic emulsifier and 30-40 parts of water in the pre-emulsification tank, fully stir and dissolve, and add the styrene, isooctyl acrylate, acrylic acid, Molecular weight modifier to obtain pre-emulsion;

[0038] 2) Polymerization: add 120-170 parts of water to the bottom of the reaction kettle, heat up to 80-90°C, stir for 20-40 minutes, first drop 0.1-0.8 parts of initiator within 5-10 minutes, and then directly drop Step 1) The obtained pre-emulsion, the dropwise addition time is 150-210 minutes, and the reaction temperature is 80-90°C;

[0039] Wherein, when the pre-emulsion has been added dropwise by 40%-60%, stop adding the remaining pre-emulsion and the remaining initiator, and put the chelating agent of the formula amount into t...

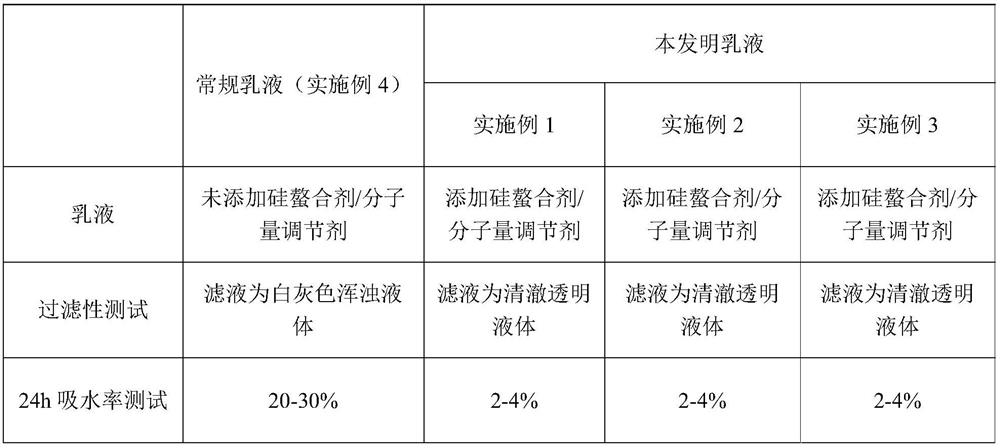

Embodiment 1

[0043] An acrylic emulsion for fiber cement board, comprising the following components in parts by mass: 180 parts of water, 50 parts of styrene, 35 parts of isooctyl acrylate, 0.5 part of acrylic acid, 1 part of anionic emulsifier, and 5 parts of chelating agent 0.5 part of molecular weight modifier, 0.2 part of initiator, 0.1 part of oxidizing agent, and 0.1 part of reducing agent.

[0044] The anionic emulsifier is sodium lauryl sulfate. Described chelating agent is ethylenediaminetetraacetic acid.

[0045] The molecular weight regulator is tertiary dodecyl mercaptan. The initiator is sodium persulfate.

[0046] As an improvement, the oxidizing agent adopts an organic peroxide. The reducing agent is sodium binitrite.

[0047] In addition, the present invention also provides the preparation method of the acrylic acid emulsion for fiber cement board, comprising the following steps:

[0048] 1) Pre-emulsification: Under normal temperature and pressure, mix the anionic emu...

Embodiment 2

[0054] An acrylic emulsion for fiber cement boards, comprising the following components in parts by mass: 260 parts of water, 60 parts of styrene, 45 parts of isooctyl acrylate, 5 parts of acrylic acid, 5 parts of anionic emulsifier, and 10 parts of chelating agent 1.5 parts of molecular weight modifier, 1 part of initiator, 0.5 part of oxidizing agent, and 0.5 part of reducing agent.

[0055] As an improvement, the anionic emulsifier is sodium dodecylbenzenesulfonate. Described chelating agent is aminotriacetic acid.

[0056] The molecular weight regulator is 2,4-diphenyl-4-methyl-1-pentene. The initiator is ammonium persulfate.

[0057] The oxidizing agent adopts organic peroxide. The reducing agent is vitamin C.

[0058] The preparation method of the acrylic acid emulsion that is used for fiber cement board, comprises the following steps:

[0059] 1) Pre-emulsification: Under normal temperature and pressure, mix the anionic emulsifier and 40 parts of water in the pre-e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com