Method of deep eutectic solvent modified lignin for epoxy resin curing agent

A technology of epoxy resin curing and low eutectic solvent, applied in the field of epoxy resin curing agent, can solve problems such as no reports yet, and achieve the effects of low price, easy reaction control, excellent operability and usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

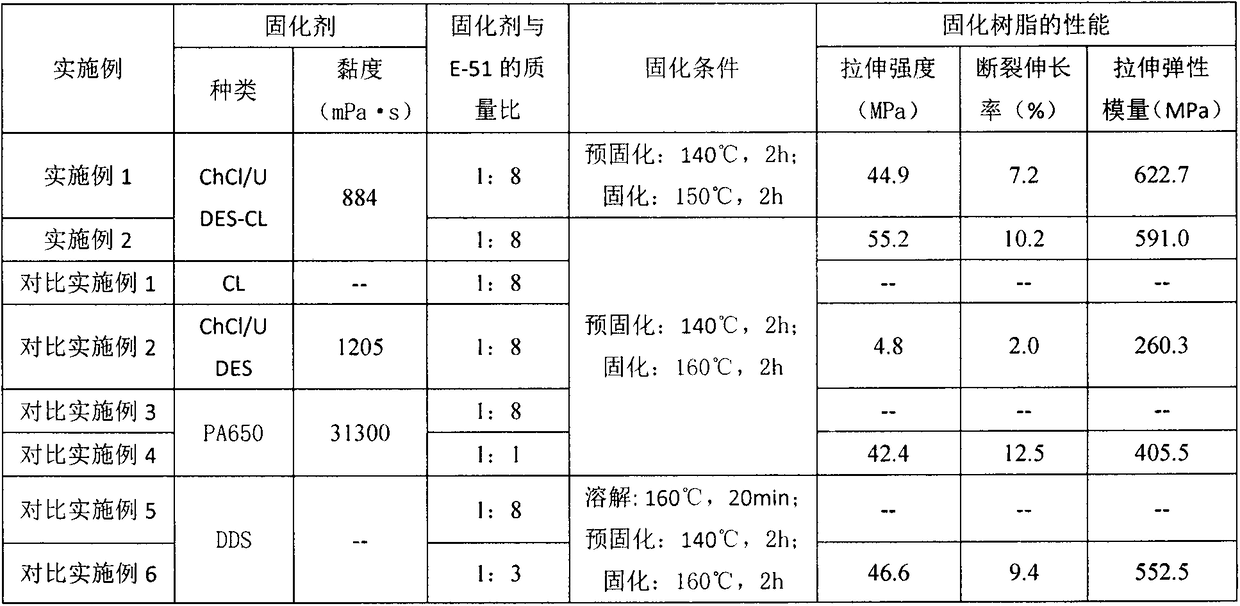

Embodiment 1

[0019] Weigh 69.8g of choline chloride (abbreviated as ChCl) and 60.0g of urea (abbreviated as U), add them into a sealed container, and stir for about 10min at 55°C until the reaction liquid is transparent, that is, choline chloride / urea Deep eutectic solvent (referred to as ChCl / UDES). Cool ChCl / U DES to 25°C and measure its viscosity to be 1205mPa·s. Weigh 3.9g of corncob enzymatic lignin (CL for short) and add it to ChCl / U DES, stir evenly, raise the temperature to 90°C, and react for 6h to obtain a mixture of choline chloride / urea deep eutectic solvent modified lignin. system (ChCl / U DES-CL for short), this mixed system is the curing agent for epoxy resin, and its viscosity at 25°C is measured to be 884mPa·s.

[0020] Weigh 7.5g of ChCl / U DES-CL curing agent, add it to 60.0g of epoxy resin E-51 and stir evenly, and pour the mixture into the preheated In a good mold, first pre-cured at 140°C for 2 hours, then cured at 150°C for 2 hours, and then naturally cooled to room ...

Embodiment 2

[0022] According to the preparation method of ChCl / U DES-CL in Example 1, ChCl / U DES-CL curing agent was prepared.

[0023] Weigh 7.5g of ChCl / U DES-CL curing agent, add it into 60.0g of epoxy resin E-51 and stir evenly, and pour the mixture into the pre- In the heated mold, pre-cure at 140°C for 2 hours, then heat-cure at 160°C for 2 hours, and then cool to room temperature naturally to prepare a cured resin sample. The measured tensile strength is 55.2MPa, elongation at break It is 10.2%, and the tensile modulus of elasticity is 591.0MPa.

Embodiment 3

[0025] According to the preparation method of ChCl / U DES-CL in Example 1, ChCl / U DES-CL curing agent was prepared.

[0026] Weigh 8.6g of ChCl / U DES-CL curing agent, add it to 60.0g of epoxy resin E-51 and stir evenly, and pour the mixture into the pre- In the heated mold, pre-cured at 140°C for 2 hours, then cured at 160°C for 2 hours, and then cooled to room temperature naturally to prepare a cured resin sample. The measured tensile strength was 24.6MPa, and the elongation at break was 4.8%, and the tensile modulus of elasticity is 488.4MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com