Water-soluble printing ink washing agent and preparation method thereof

A technology for printing ink and cleaning agent, applied in the field of water-soluble printing ink cleaning agent and its preparation, can solve the problems of corrosion, penetration of objects, poor cleaning effect of cleaning agent, etc., and achieves strong detergency, shortened service life, environmental protection and the effect of less harm to personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A water-soluble printing ink cleaning agent, the sum of the mass ratios of all components is 100%, according to the total mass of the water-soluble printing ink cleaning agent is 1kg, raw materials include: 5% ethylene glycol monomethyl ether, citric acid Sodium 2%, malic acid 1%, Surfynol 465 1%, Indian drytech company's printed gum arabic lithogum acacia 1%, triethanolamine 1%, fatty alcohol polyoxyethylene ether 0.5%, fatty alcohol polyoxyethylene ether sodium sulfate 0.5 %, sodium benzoate 0.3%, benzotriazole 0.3%, hexamethylenetetramine 0.3%, bentonite 1%, and the rest is deionized water.

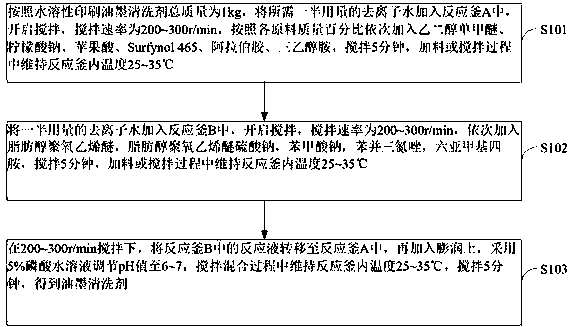

[0036] The preparation method of this water-soluble printing ink cleaning agent comprises the following steps:

[0037] S101. According to the total mass of the water-soluble printing ink cleaning agent is 1kg, add half of the required amount of deionized water into the reaction kettle A, start stirring at a stirring rate of 200~300r / min, and add ethylene glycol in sequence acco...

Embodiment 2

[0044] A water-soluble printing ink cleaning agent, the sum of all component mass ratios is 100%, according to the total mass of the water-soluble printing ink cleaning agent is 1kg, raw materials include: ethylene glycol monomethyl ether 10%, citric acid Sodium 3%, malic acid 2%, Surfynol 465 2%, Indian drytech company's printed gum arabic lithogum acacia 2%, triethanolamine 2%, fatty alcohol polyoxyethylene ether 1%, fatty alcohol polyoxyethylene ether sodium sulfate 1 %, sodium benzoate 0.5%, benzotriazole 0.5%, hexamethylenetetramine 0.5%, bentonite 2%, and the rest is deionized water.

[0045] The preparation method of this water-soluble printing ink cleaning agent comprises the following steps:

[0046] S201. According to the total mass of the water-soluble printing ink cleaning agent is 1kg, add half of the required amount of deionized water into the reaction kettle A, start stirring at a stirring rate of 200~300r / min, and add ethylene glycol in sequence according to th...

Embodiment 3

[0052]A water-soluble printing ink cleaning agent, the sum of all component mass ratios is 100%, according to the total mass of the water-soluble printing ink cleaning agent is 1kg, raw materials include: 7.5% ethylene glycol monomethyl ether, citric acid Sodium 2.5%, malic acid 1.5%, Surfynol 465 1.5%, Indian drytech company's printed gum arabic lithogum gum arabic 1.5%, triethanolamine 1.5%, fatty alcohol polyoxyethylene ether 0.75%, fatty alcohol polyoxyethylene ether sodium sulfate 0.75 %, sodium benzoate 0.4%, benzotriazole 0.4%, hexamethylenetetramine 0.4%, bentonite 1.5%, and the rest is deionized water.

[0053] The preparation method of this water-soluble printing ink cleaning agent comprises the following steps:

[0054] S301. Add half of the required amount of deionized water into the reaction kettle A, start stirring at a stirring rate of 200~300r / min, and add ethylene glycol monomethyl ether, sodium citrate, malic acid, Surfynol 465, gum arabic, triethanolamine, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com