A kind of preparation method of copper gallium alloy, silver gallium alloy

A copper-gallium alloy and silver-gallium technology is applied in the preparation field of copper-gallium alloy and copper-silver alloy, which can solve the problems of affecting the effect of forming alloys, complex system equipment, poor fusion effect, etc., achieving excellent industrial production prospects and simple operation process. , to avoid the effect of high temperature environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

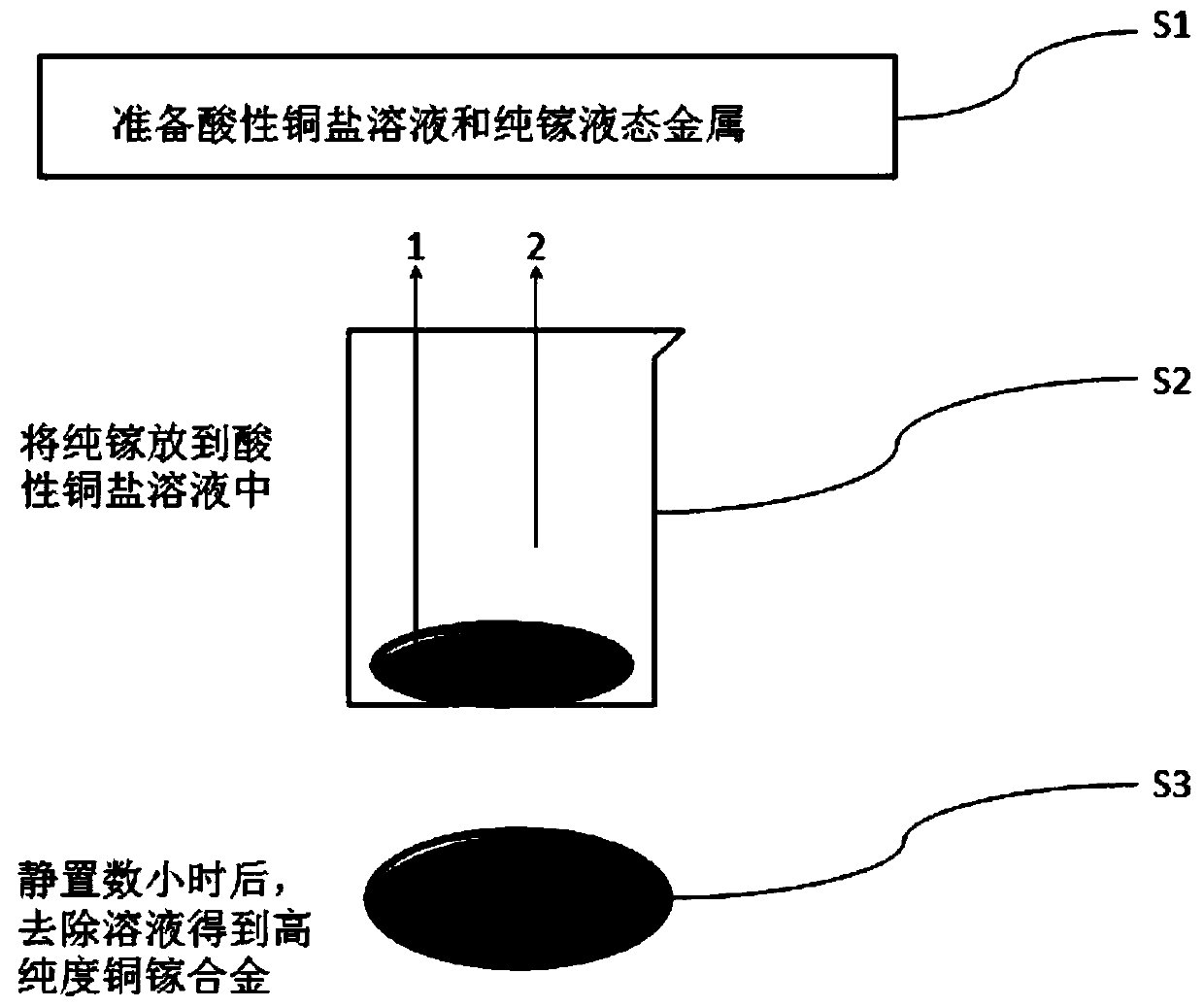

[0035] by figure 1 The schematic diagram of the preparation method of copper-gallium alloy is shown in the flow chart, which mainly includes:

[0036] S1: prepare acidic copper salt solution and pure gallium;

[0037] S2: Put pure gallium in an acidic copper salt solution, and heat the solution to a temperature higher than 29°C until the gallium becomes completely liquid;

[0038] S3: Stand still for several hours, after the reaction is complete and the solution becomes transparent, remove the solution to obtain a high-purity copper-gallium alloy.

Embodiment 1

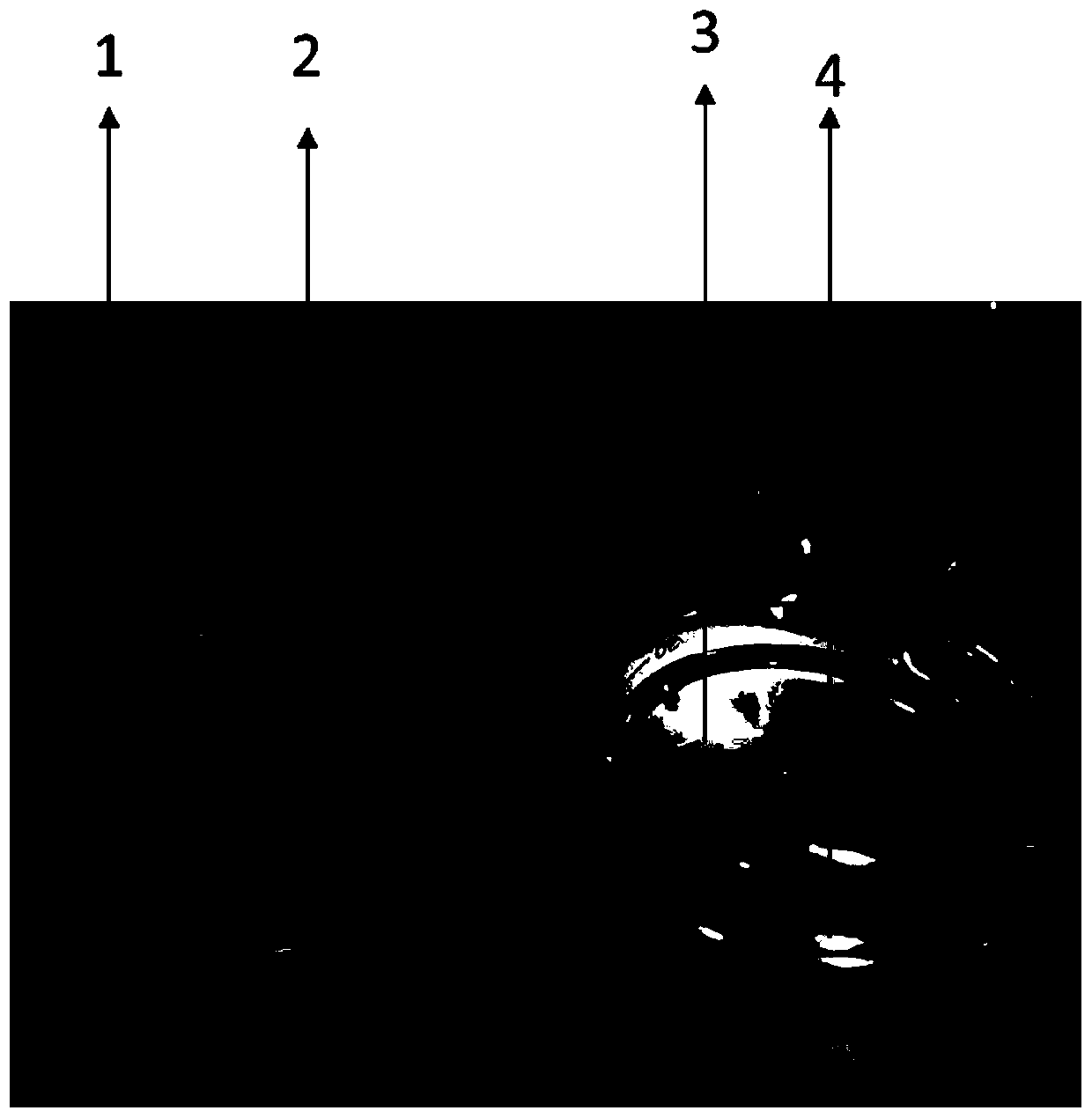

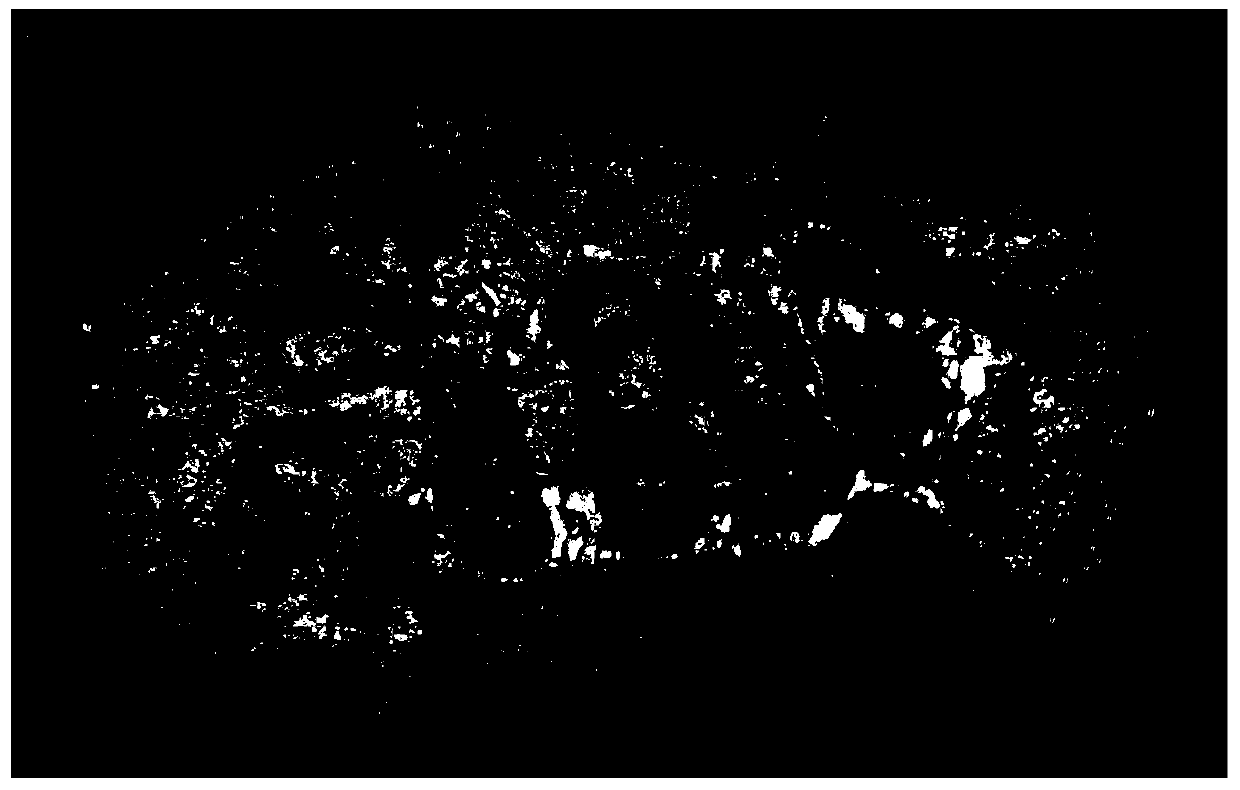

[0040] 5ml mass concentration is that the cupric chloride solution of 10% and the hydrochloric acid solution that 5ml molar concentration is 2mol / L are mixed to form acidic cupric chloride solution, adds 6g pure gallium ( figure 2 A), be heated to 30 ℃, until gallium becomes liquid completely; Stand still, until solution becomes transparent color ( figure 2 B), remove solution and obtain high-purity copper-gallium alloy ( image 3 ).

[0041] The copper-gallium alloy prepared in this embodiment is tested for its elemental composition by energy spectrum testing, and it is found that it is mainly composed of copper and gallium ( Figure 4 ), which proved the successful preparation of copper-gallium alloy with higher purity.

[0042] Reaction principle: Because gallium and copper have different electrode potentials in acidic solution, gallium is more active than copper. Thus gallium can reduce copper out of solution. At the same time, because of the good wettability between...

Embodiment 2

[0044] Mix 5ml of silver nitrate solution with a mass concentration of 20% and 5ml of nitric acid solution with a molar concentration of 2mol / L to form an acidic silver nitrate solution, add 10g of pure gallium therein, and heat to 30°C until the gallium becomes liquid completely; Stand still until the solution becomes transparent, and remove the solution to obtain a high-purity silver-gallium alloy.

[0045] The element composition contained in the silver-gallium alloy prepared in this embodiment was also tested by energy spectrum test, and it was found that it was mainly composed of silver and gallium, which proved that the silver-gallium alloy with high purity was successfully prepared.

[0046] Reaction principle is similar to embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com