Building with precast reinforced concrete supports

A technology of concrete support and reinforced concrete, which is applied in the direction of buildings, building components, building structures, etc., and can solve the problems of limited connection space of reinforcement bars in two-way stressed cavity floors, cumbersome connection of reinforcement bars, and large components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The invention will be further described below in conjunction with the accompanying drawings.

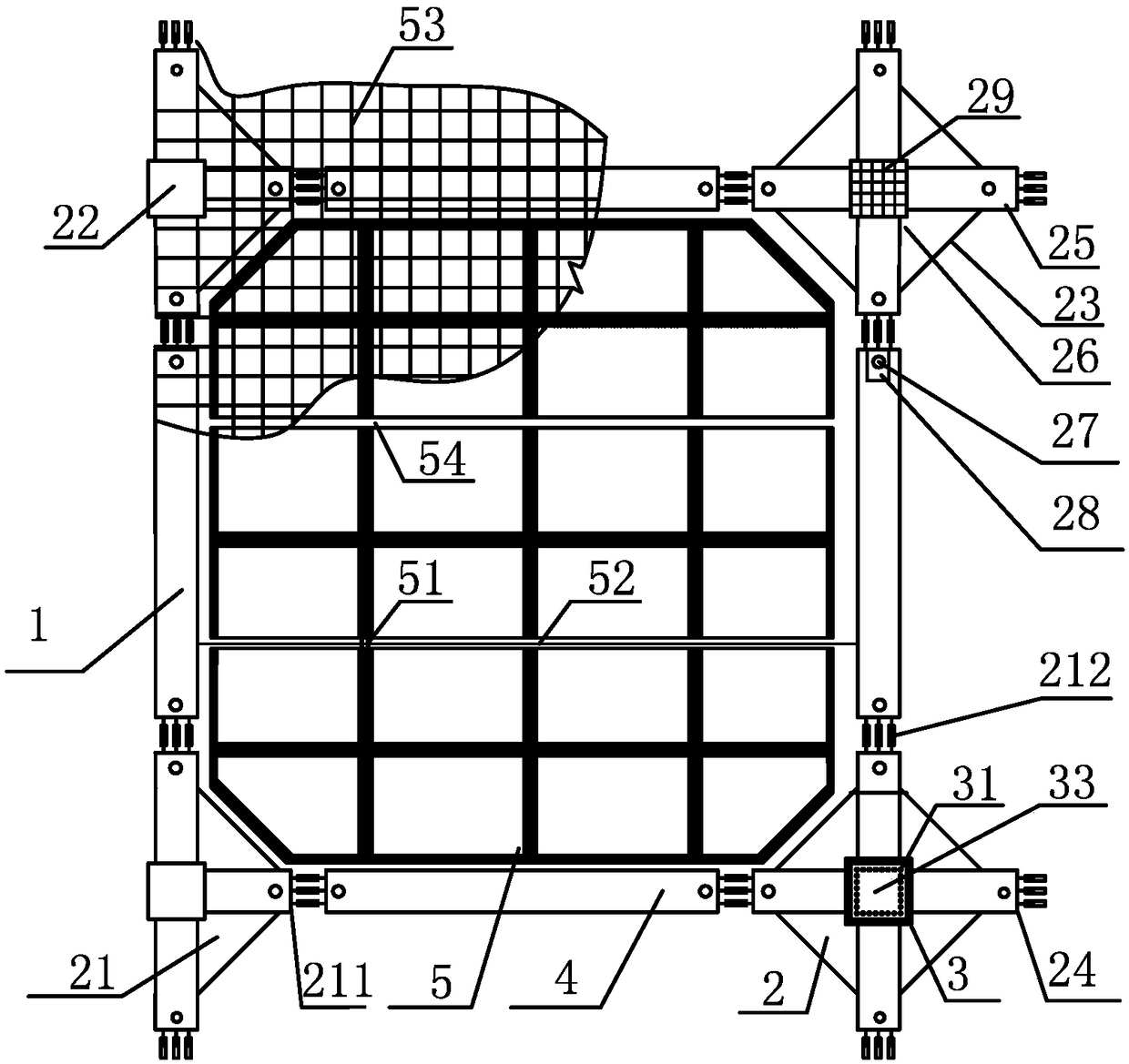

[0025] figure 1 It is a plane embodiment diagram of the frame structure of the present invention, during the implementation of the present invention;

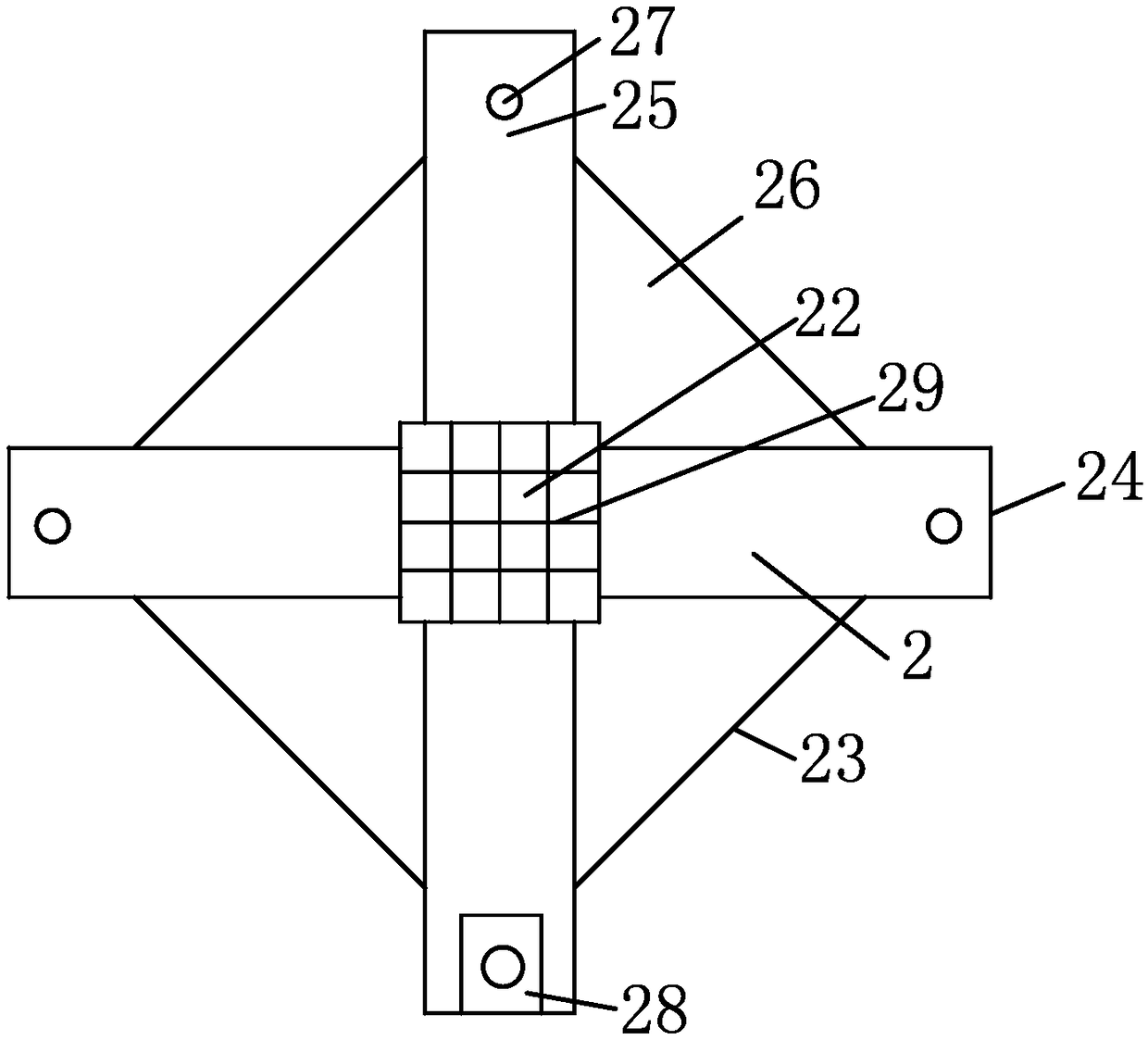

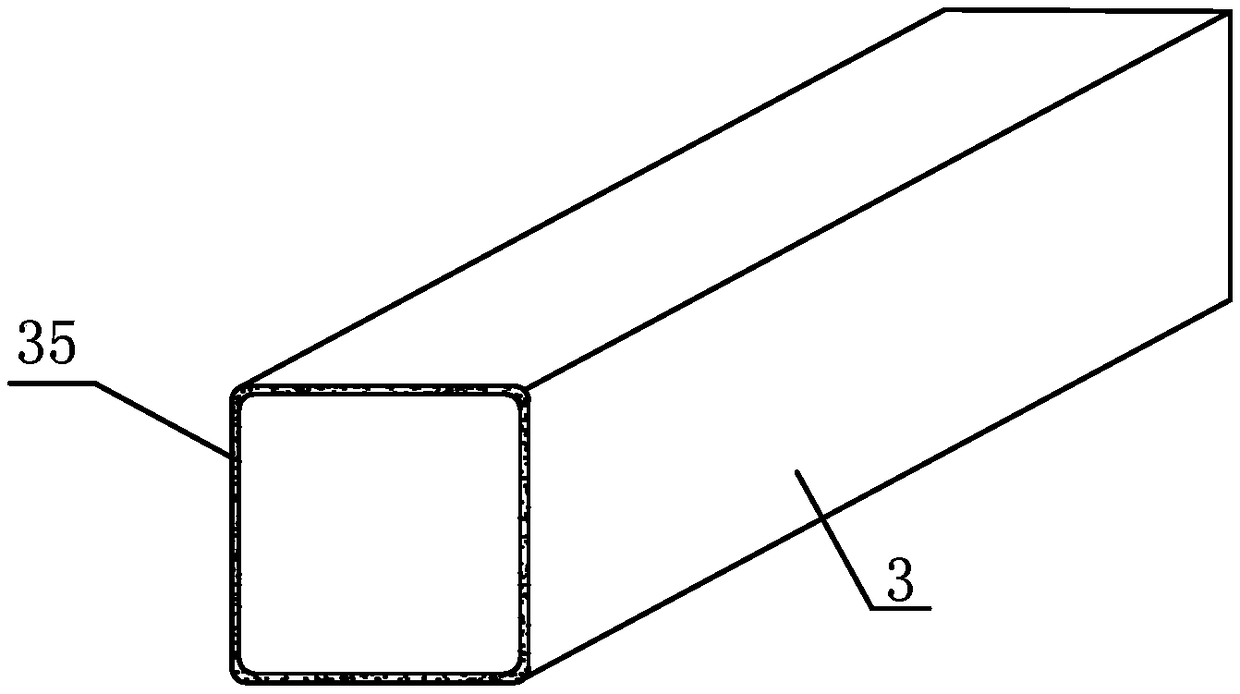

[0026] Step 1: Manufacture the prefabricated concrete column frame 3 of the specifications and models required by the frame structure 1, the diamond-shaped prefabricated reinforced concrete support body 2 or the triangular prefabricated reinforced concrete support body 21, the prefabricated main beam 4, the prefabricated stairs, and the cavity Floor 5 and column reinforcement 31; diamond-shaped prefabricated reinforced concrete support body 2 includes main beam assembly end 24, square column hole 22 in the middle of the support, rhombus side 23, water chestnut 25, reinforced concrete between beams 26, and bolt holes 27 , the main beam connecting steel plate 28, the main beam cross reinforcement 29 in the square column hole 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com