Method for determining content of neodymium fluoride and lithium fluoride in neodymium production electrolyte

A measurement method and electrolyte technology, which is applied in the field of electrolysis, can solve the problems of no chemical analysis, etc., and achieve the effect of fast analysis speed, high accuracy, and reliable analysis data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

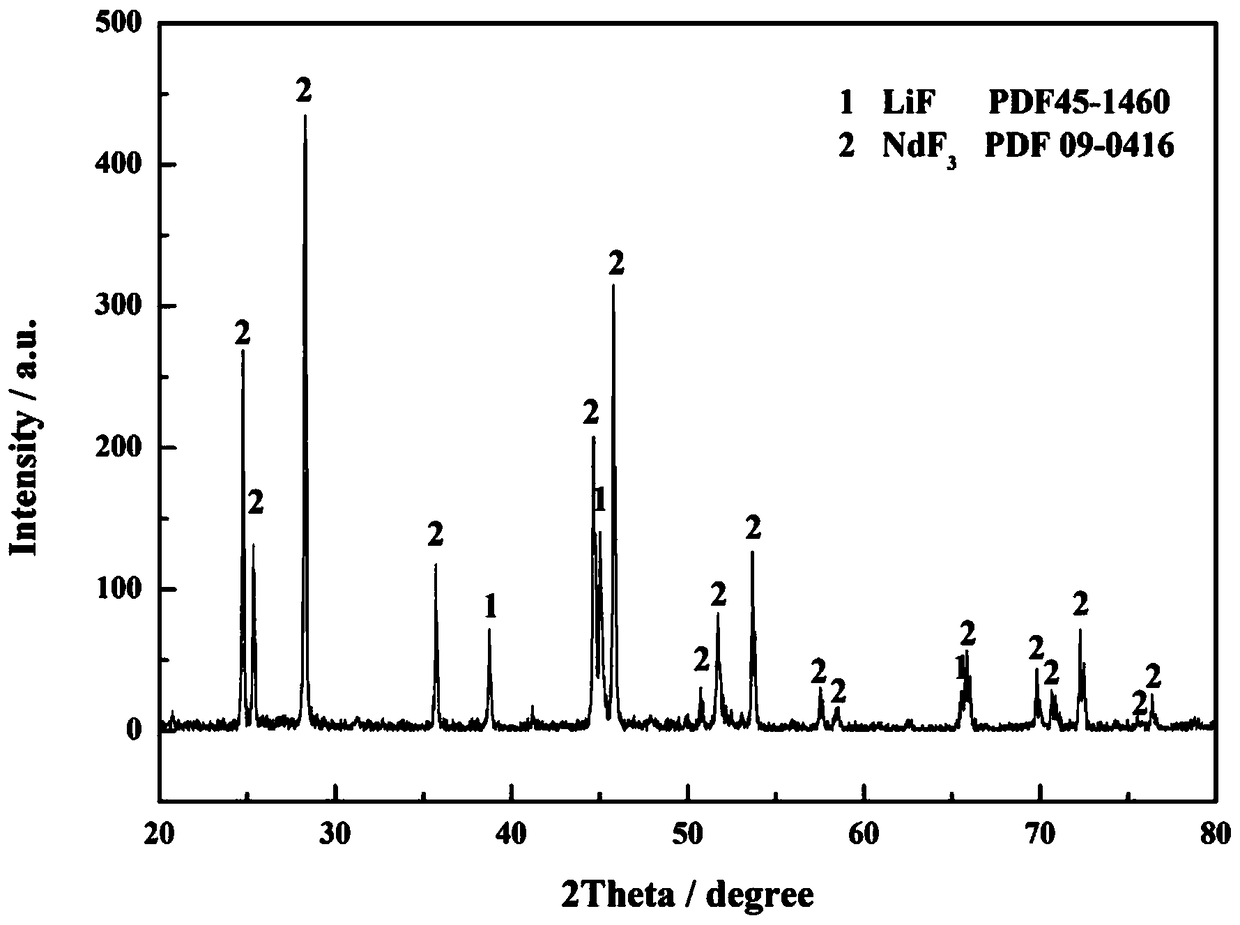

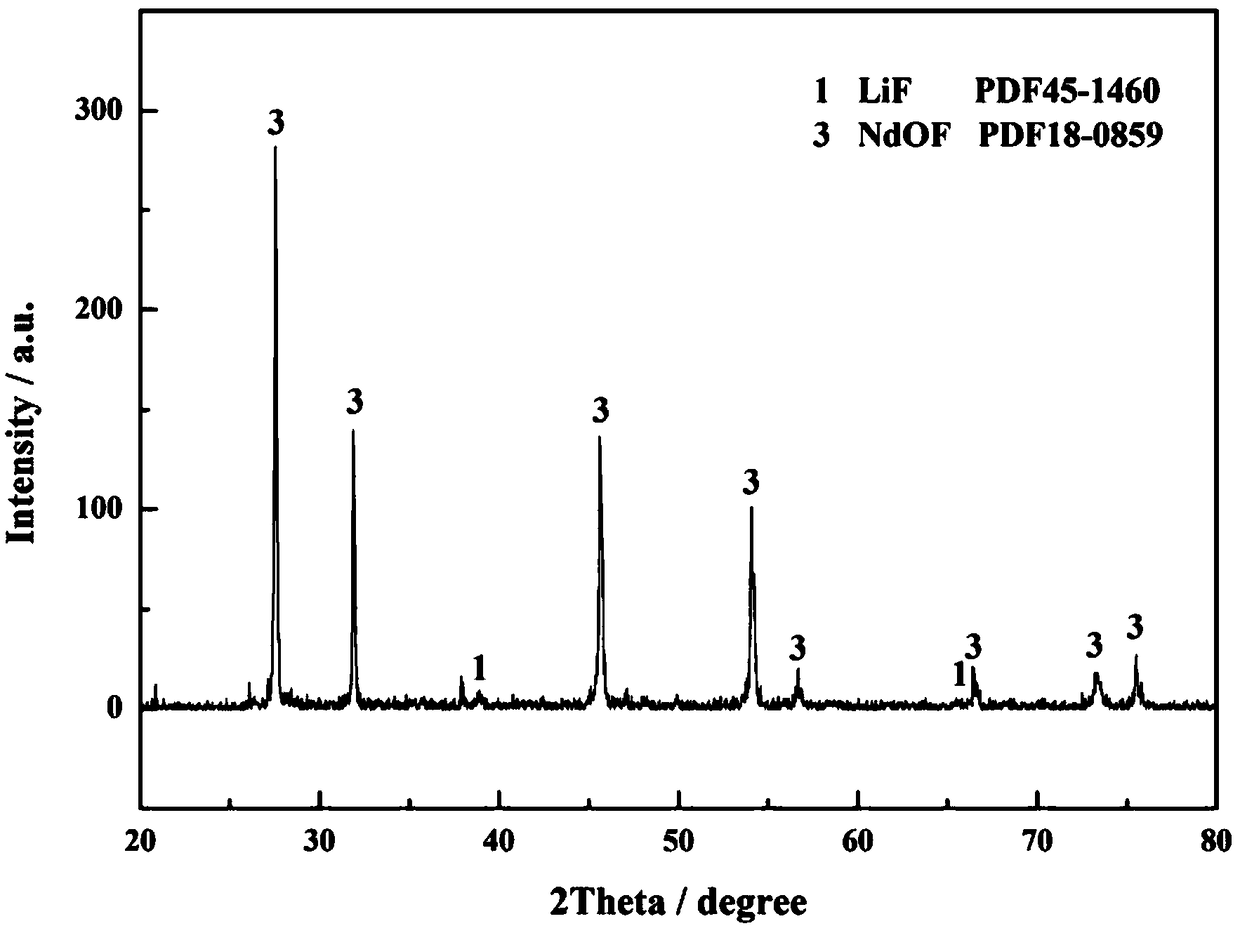

Image

Examples

Embodiment 1

[0030] This embodiment provides a method for determining the content of neodymium fluoride and lithium fluoride in the electrolyte for the production of neodymium, including the following steps.

[0031] (1) Pipette 0.00, 0.50, 1.00, 5.00, 10.00, 20.00, 50.00mL of neodymium standard solution into seven 100mL volumetric flasks respectively, and use a 5% nitric acid solution to set the volume to the mark, shake well, and The solution was introduced into an inductively coupled plasma emission spectrometer to obtain a standard working curve for neodymium.

[0032] (2) Pipette 0.00, 0.50, 1.00, 2.00, 5.00, 10.00mL lithium standard solution into six 100mL volumetric flasks, dilute to the mark with 5% nitric acid solution, shake well, and introduce the obtained solution into In the inductively coupled plasma optical emission spectrometer, the lithium standard working curve was obtained.

[0033] (3) According to the composition of neodymium production electrolyte, weigh 6g LiF (mass...

Embodiment 2

[0045] This embodiment provides a method for determining the content of neodymium fluoride and lithium fluoride in the electrolyte for the production of neodymium, including the following steps.

[0046] (1) Pipette 0.00, 0.50, 1.00, 5.00, 10.00, 20.00, 50.00mL of neodymium standard solution into seven 100mL volumetric flasks respectively, and use a 5% nitric acid solution to set the volume to the mark, shake well, and The solution was introduced into an inductively coupled plasma emission spectrometer to obtain a standard working curve for neodymium.

[0047] (2) Pipette 0.00, 0.50, 1.00, 2.00, 5.00, 10.00mL lithium standard solution into six 100mL volumetric flasks, dilute to the mark with 5% nitric acid solution, shake well, and introduce the obtained solution into In the inductively coupled plasma optical emission spectrometer, the lithium standard working curve was obtained.

[0048] (3) According to the composition of neodymium production electrolyte, weigh 6g LiF (mass...

Embodiment 3

[0060] This embodiment provides a method for determining the content of neodymium fluoride and lithium fluoride in the electrolyte for the production of neodymium, including the following steps.

[0061] (1) Pipette 0.00, 0.50, 1.00, 5.00, 10.00, 20.00, 50.00mL of neodymium standard solution into seven 100mL volumetric flasks respectively, and use a 5% nitric acid solution to set the volume to the mark, shake well, and The solution was introduced into an inductively coupled plasma emission spectrometer to obtain a standard working curve for neodymium.

[0062] (2) Pipette 0.00, 0.50, 1.00, 2.00, 5.00, 10.00mL lithium standard solution into six 100mL volumetric flasks, dilute to the mark with 5% nitric acid solution, shake well, and introduce the obtained solution into In the inductively coupled plasma optical emission spectrometer, the lithium standard working curve was obtained.

[0063] (3) According to the composition of neodymium production electrolyte, weigh 6g LiF (mass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com