Preparation method for metal organic framework material-heme-based electrochemical sensor and application thereof

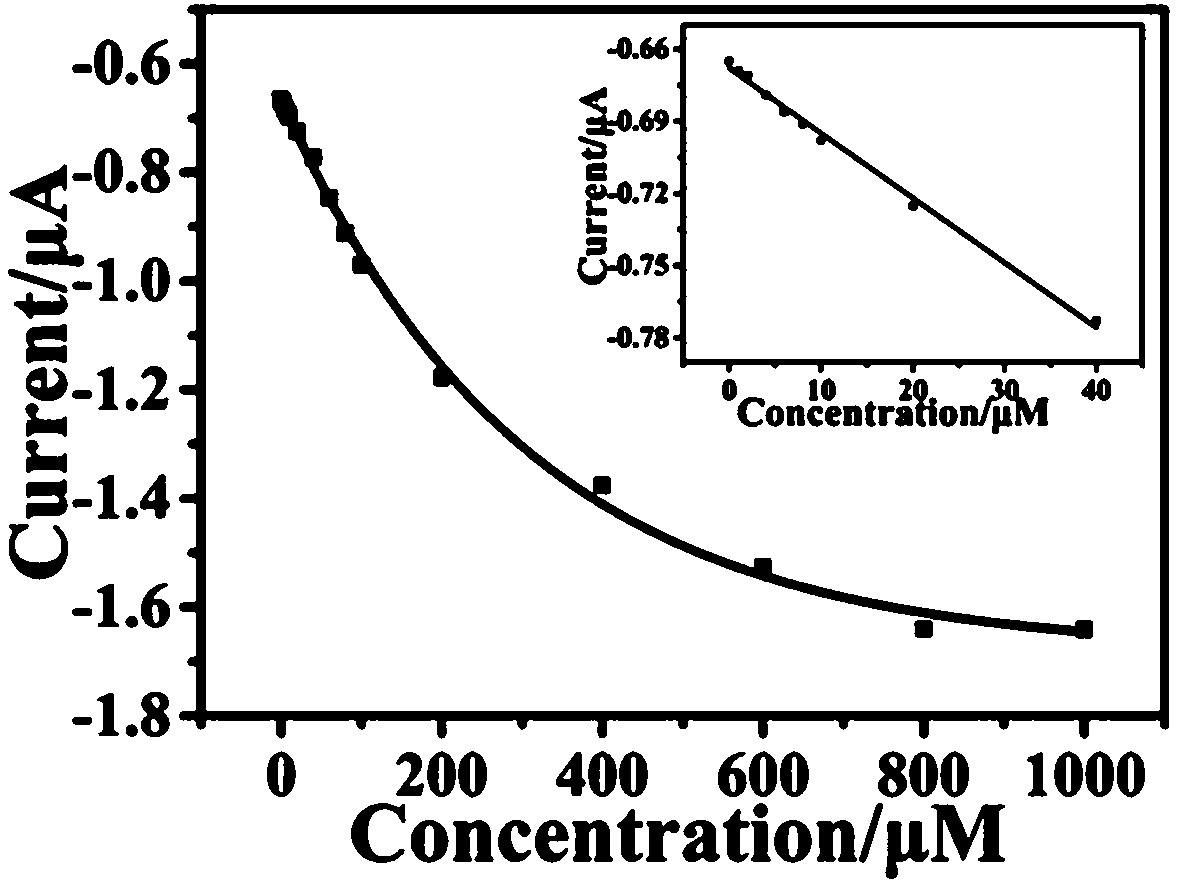

A metal-organic framework and heme technology, applied in the direction of material electrochemical variables, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problem of poor catalytic activity and stability, and poor catalytic activity of heme , poor stability of heme, etc., to achieve the effects of fast sensitivity, high electrochemical catalytic activity, enhanced stability and catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method based on a metal organic framework material-heme electrochemical sensor is carried out as follows:

[0026] 1) Synthesis of MOFs: Weigh 0.166 g of terephthalic acid and 0.096 g of nickel nitrate hexahydrate, mix them in 20 mlml N,N-dimethylformamide (DMF), and add 2 ml of 0.4 M NaOH solution, closed the reaction vessel, and reacted at 100°C for 8 h; after the reaction, cooled to room temperature, washed the obtained precipitate with DMF and absolute ethanol three times, and centrifuged and dried to obtain nickel-MOFs nano Material.

[0027] 2) Preparation of MOFs-heme nanocomposites: Weigh 0.1 g hemin and dissolve it in 30 ml DMF, then add 4 ml freshly prepared 0.1 M NaOH solution, mix well, sonicate for 30 min, and then add 0.1 g MOFs Sonicate for 3 min, then stir for 15 min, close the reactor, and place it in an oven at 100°C for 24 h. The obtained precipitates were washed three times with DMF and absolute ethanol, and dried to obtain pure MOFs-...

Embodiment 2

[0036] A preparation method based on a metal organic framework material-heme electrochemical sensor, comprising the steps of:

[0037] 1) Synthesis of MOFs: Mix terephthalic acid and nickel nitrate hexahydrate in DMF, add NaOH solution drop by drop under stirring conditions, close the reaction vessel, and react at 100±5°C for 7-9 h; After finishing, cool down to room temperature, wash the obtained precipitate with DMF and absolute ethanol for more than 3 times, and obtain nickel-MOFs nanomaterials after drying.

[0038] In this step, the mol ratio of terephthalic acid, nickel nitrate hexahydrate and NaOH is 3: 0.95: 2.3; the consumption of DMF is 70 times of the quality sum of terephthalic acid and nickel nitrate; The molarity is 0.35 mol / l.

[0039] 2) Preparation of MOFs-heme nanocomposites: Mix hemin and MOFs at a mass ratio of 1:0.95, dissolve in DMF, add NaOH solution to it, react at 100±5°C for 18 hours, and cool to room temperature; The obtained precipitates were wash...

Embodiment 3

[0049] A preparation method based on a metal organic framework material-heme electrochemical sensor, comprising the steps of:

[0050] 1) Synthesis of MOFs: Mix terephthalic acid and nickel nitrate hexahydrate in DMF, add NaOH solution drop by drop under stirring conditions, close the reaction vessel, and react at 105°C for 9 h; after the reaction, cool After reaching room temperature, the obtained precipitates were washed three times with DMF and absolute ethanol, and dried to obtain nickel-MOFs nanomaterials.

[0051] In this step, the mol ratio of terephthalic acid, nickel nitrate hexahydrate and NaOH is 3: 0.95: 2.5; the consumption of DMF is 74 times of the quality sum of terephthalic acid and nickel nitrate; The molarity is 0.35 mol / l.

[0052] 2) Preparation of MOFs-heme nanocomposites: Mix hemin and MOFs at a mass ratio of 1:0.95, dissolve in DMF, add NaOH solution to it, react at 105°C for 30 h, and cool to room temperature; The obtained precipitates were washed thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com