Solar cell mask for spin coating process

A technology of solar cells and spin coating technology, applied in the field of mask plates, can solve the problems of inconvenient adjustment and movement of glass substrates, inconvenience in distinguishing cell efficiency in regions with different cell thicknesses, and inability to reflect electrical differences, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

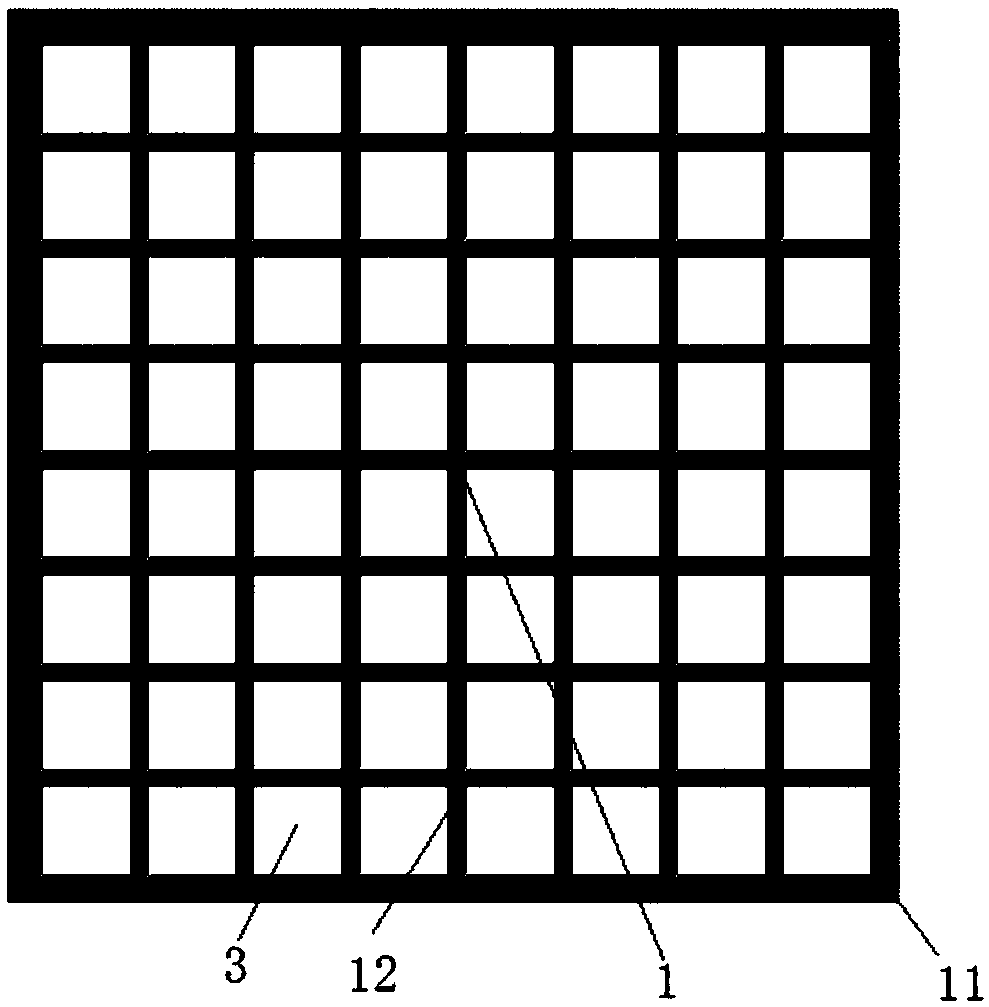

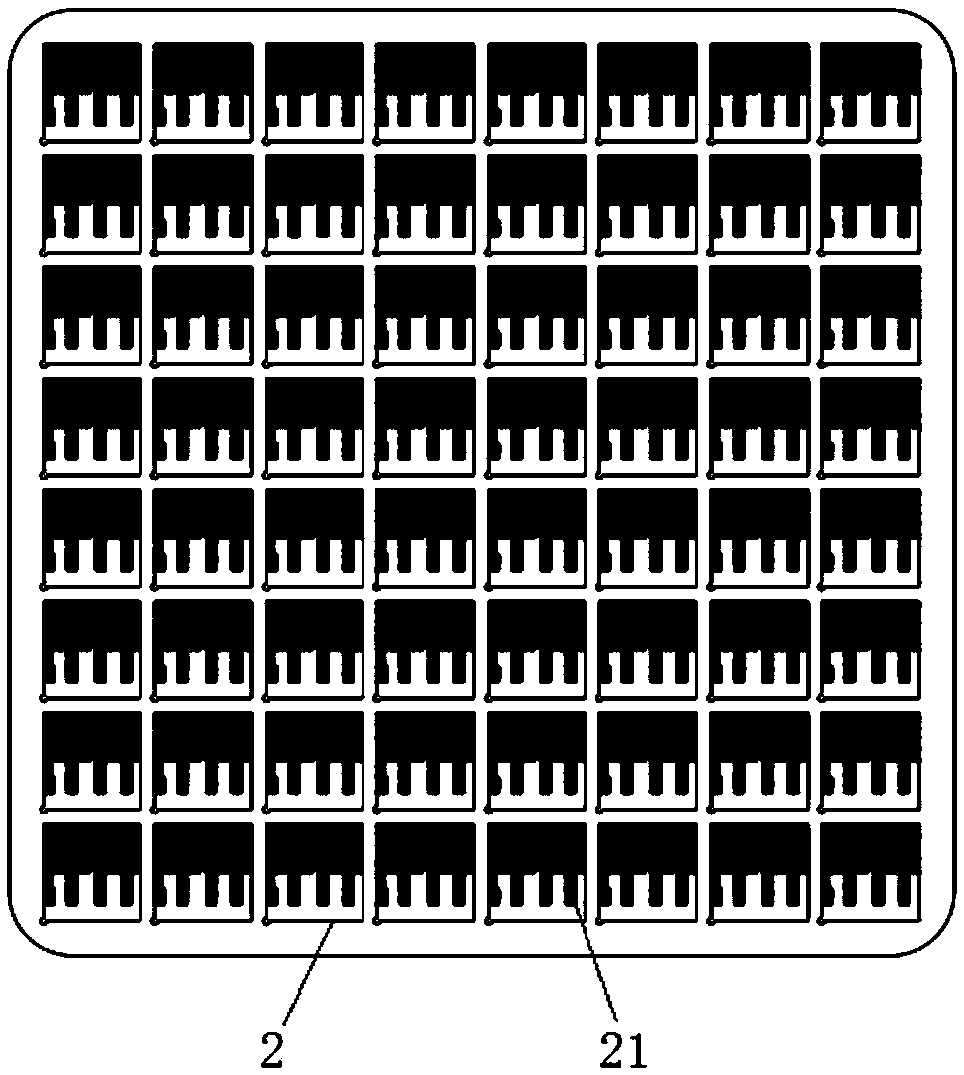

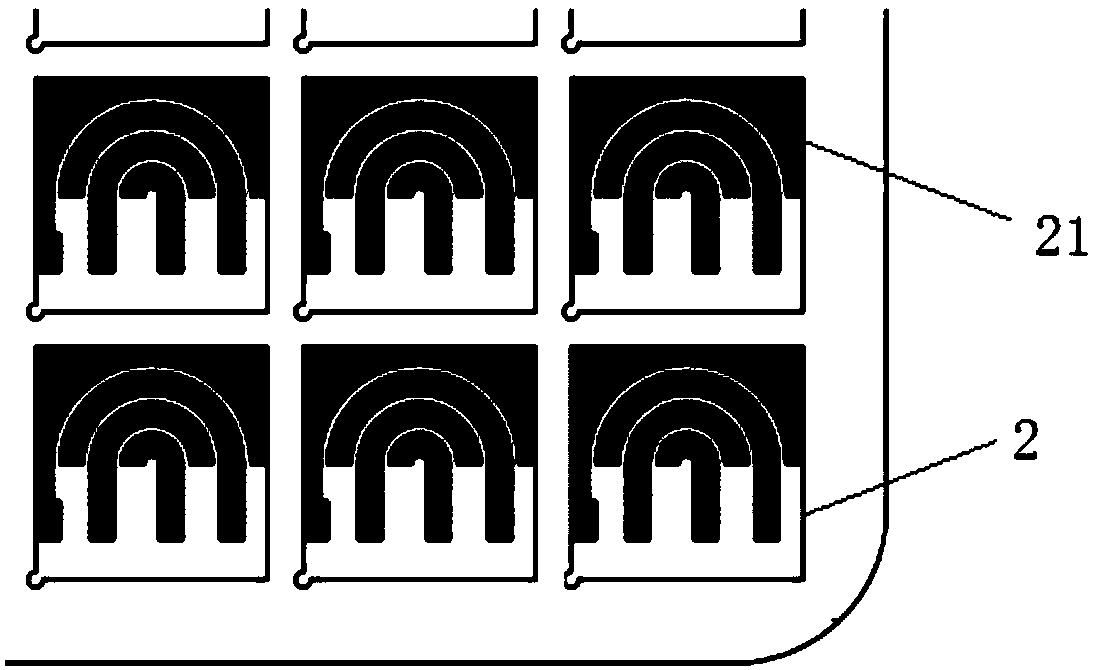

[0038] A solar cell mask used for spin-coating process, the outer frame 1 is made of steel plate with a thickness of 1.25 mm, which is the same thickness as the laboratory glass substrate, the outer frame 11 and the separator 12 of the outer frame 1 will mask The template is divided into a total of 64 square grids 3 of 8×8, and the interval between the grids is 2.5 mm. The grids of the electrode layout sheet 2 are set in one-to-one correspondence with the grids 3 of the frame frame 1, and are fixed by welding with the frame frame 1; the electrode layout sheet 2 is made of a steel plate with a thickness of 0.2 mm; the electrode layout sheet 2 is provided with a coating area 21, The coating area is composed of a ring structure 221 and a rectangular structure 222; except for the coating area 21 on the electrode layout thin plate 2, other parts are covered by a mask.

[0039] Other structural forms of the present invention can change the size and quantity of the annular area of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com