Vertical honeycomb sandwich plate, preparation method and sandwich plate connecting method

A technology of honeycomb sandwich panel and connection method, which is applied in the direction of layered products, transportation and packaging, vehicle parts, etc., and can solve the problem of poor sound insulation and heat insulation performance of honeycomb sandwich panels, poor bonding strength between core material and panel, and polymer materials. There are few types of applications, etc., to achieve the effect of increasing the maximum bearing capacity, improving the diversification of functions, and improving the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

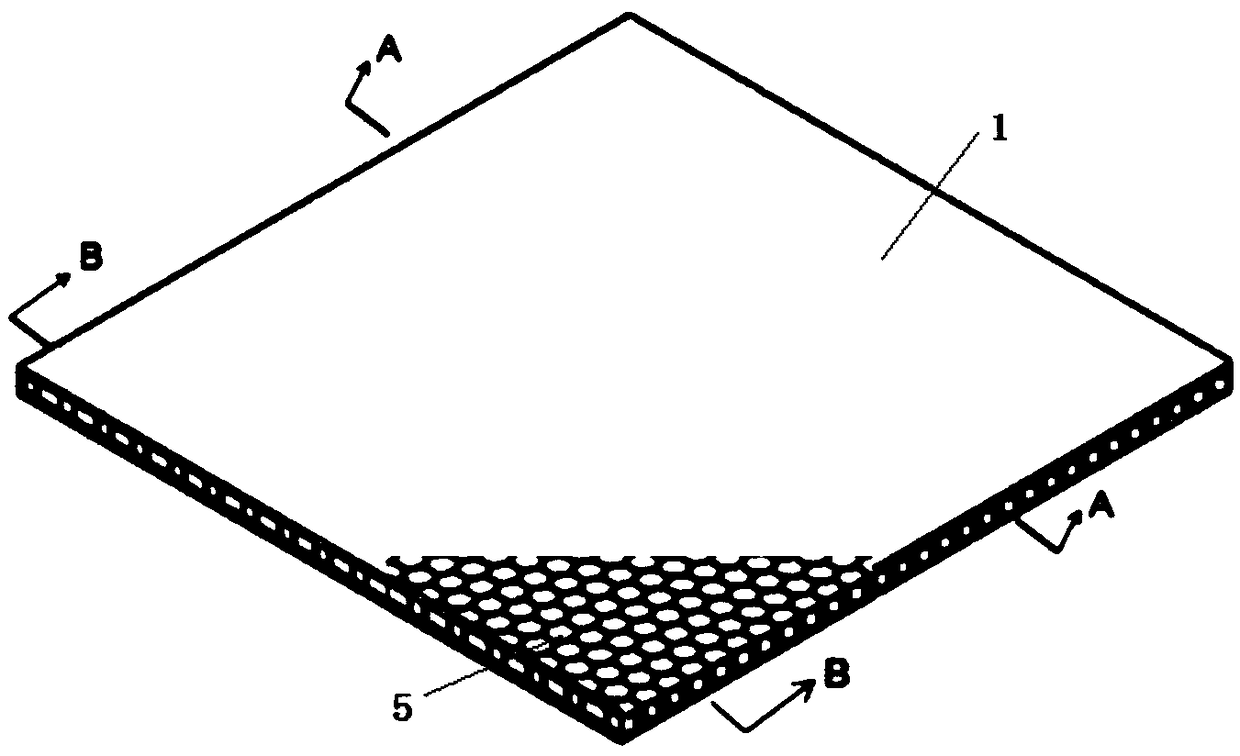

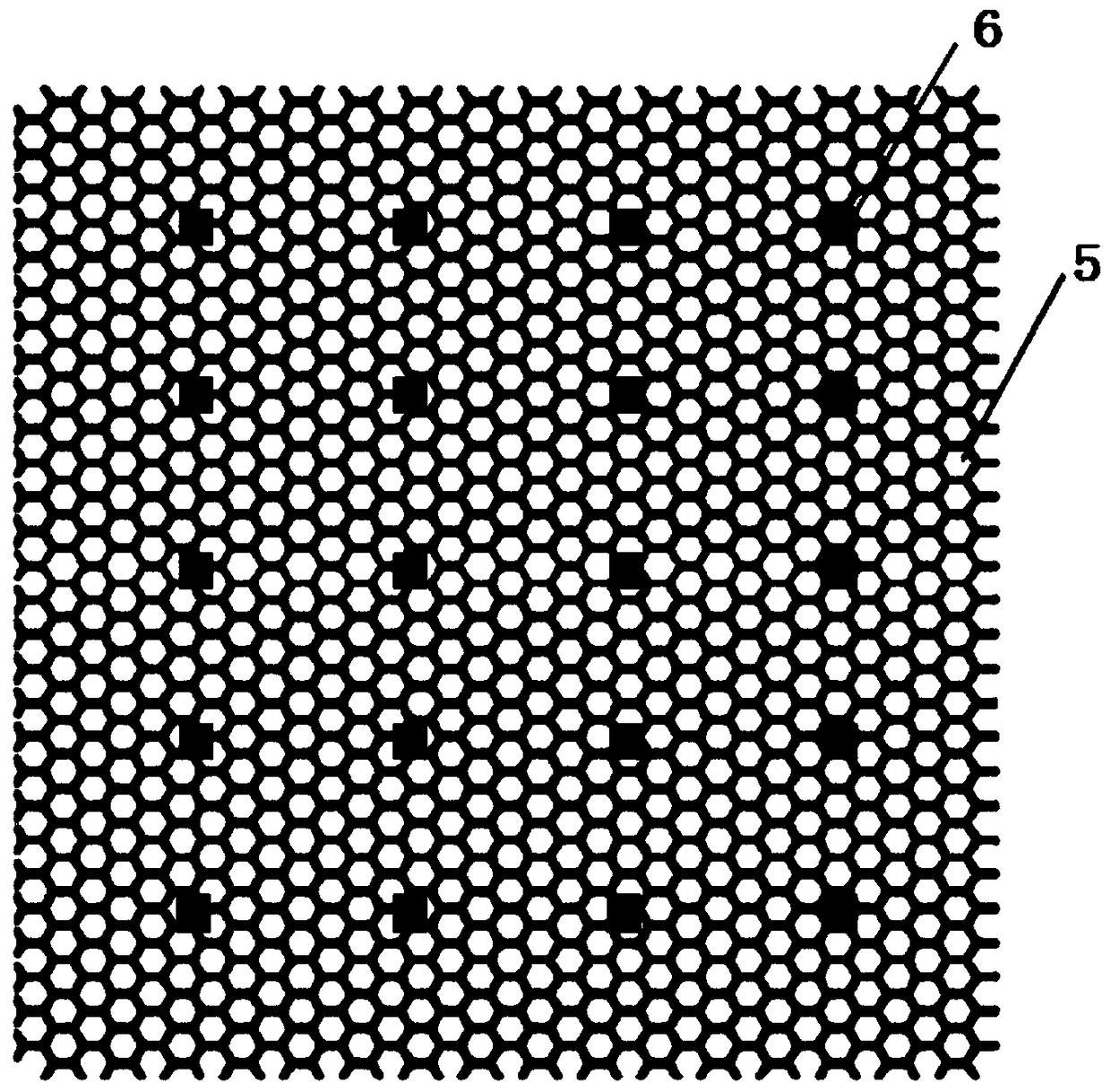

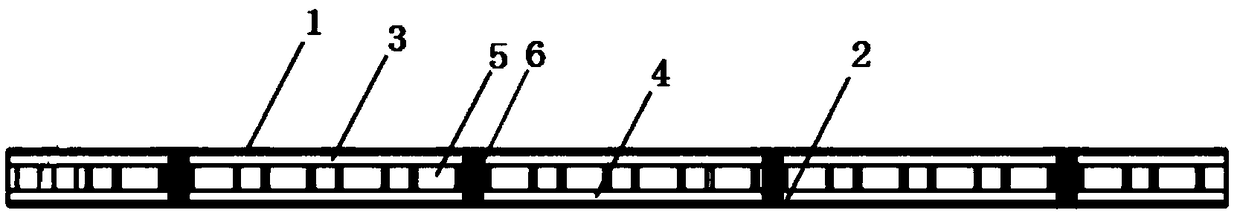

[0039]The preparation method of the vertical honeycomb sandwich panel of the present invention comprises the following steps: first, the honeycomb holes of the honeycomb layer 5 are filled with foam material, and the honeycomb holes for penetrating several columns 6 are arranged, and then one end of several columns 6 is connected with the lower After the panel 2 is fixedly connected, the honeycomb layer 5 is set, and the upper panel 1 and the other end of the column 6 are connected and fixed, and the glue layer material is respectively poured between the upper panel 1 and the honeycomb layer 5, and between the lower panel 2 and the honeycomb layer 5, The upper glue layer 3 and the lower glue layer 4 are formed to make a vertical honeycomb sandwich panel.

[0040] In addition, in the above preparation method, when casting the upper glue layer 3 and the lower glue layer 4, a C-shaped plate is used to seal the boundary, so that no leakage of material can be achieved during the cas...

Embodiment 1

[0049] In this embodiment, the upper and lower panels are made of Q235 steel, the glue layer and honeycomb layer honeycomb framework are polyurethane elastomers, and the foam material filled in the honeycomb layer is polyurethane foam material.

[0050] The specific parameters are: the upper and lower panels are made of Q235 steel, and its elastic modulus is 2.1×10 5 MPa, Poisson's ratio 0.3, density 7850kg / m 3 . The adhesive layer structure adopts the "PTMEG+TDI" system, with an elastic modulus of 300MPa, a tensile strength of 60MPa, a hardness of Shore D65, and a density of 1.13kg / dm 3 . The main frame structure of the honeycomb layer adopts the "DP400+MDI" system, with an elastic modulus of 2400MPa, a tensile strength of 75MPa, a Shore hardness of D80, and a density of 1.14kg / dm 3 , the skeleton structure can be prefabricated by preparing molds and pouring. Its structural form can be a hexagonal structure, or a triangular or circular cross-sectional structure. After the ...

Embodiment 2

[0055] In this embodiment, FRP is used as the panel material, the polyurethane elastomer is used as the adhesive layer and the honeycomb skeleton material, and the polyurethane foam is used as the foam filling material of the honeycomb layer. Specifically, the upper and lower parts are made of glass fiber reinforced plastic with a density of 1600Kg / m 3 , the modulus of elasticity is 72GPa, and Poisson's ratio is 0.2. The adhesive layer structure adopts the "PTMEG+TDI" system, with an elastic modulus of 300MPa, a tensile strength of 60MPa, a hardness of Shore D65, and a density of 1.13kg / dm 3 . The main frame structure of the honeycomb layer adopts the "DP400+MDI" system, with an elastic modulus of 2400MPa, a tensile strength of 75MPa, a Shore hardness of D80, and a density of 1.14kg / dm 3 . The foam filling material adopts the "PPG1000+TDI+water-based blowing agent" system. The panel in this embodiment is made of non-weldable material, and may also be carbon fiber, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com